An oil cylinder device for cushioning after unloading

A rear buffer and oil cylinder technology, applied in the direction of fluid pressure actuation device, etc., can solve the problems of poor buffer effect and large buffer stroke, and achieve the effects of smooth buffering, shortening buffer stroke and reducing peak value.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

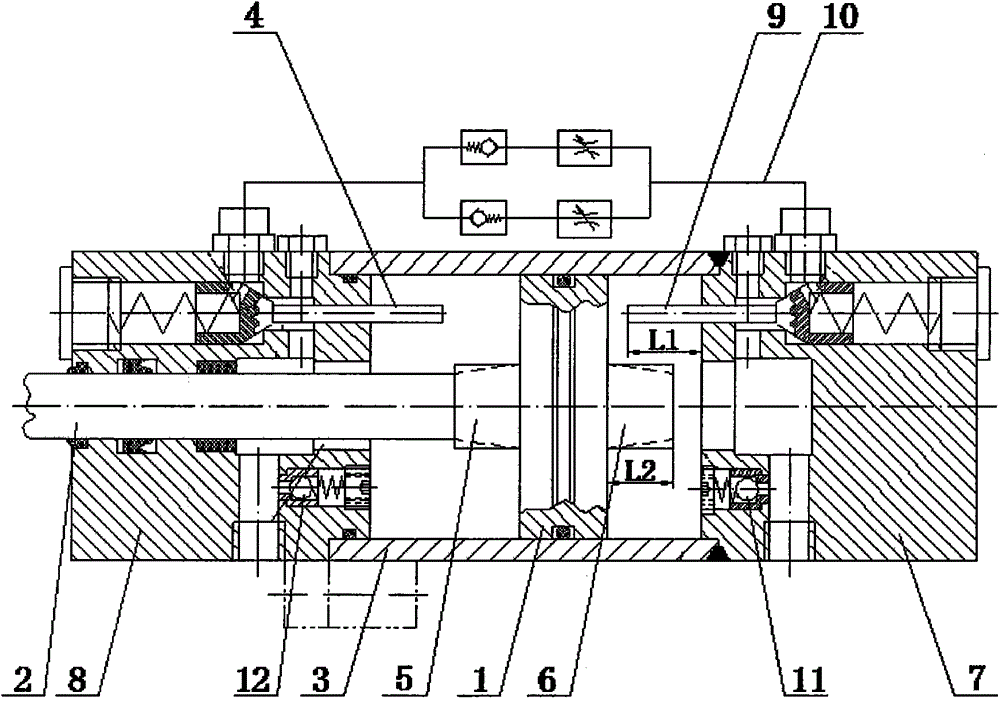

[0029] An oil cylinder device for cushioning after unloading of the present invention comprises: a cylinder bottom 7, a cylinder barrel 3, a cylinder cover 8, a buffer piston and two check valve pistons with the same structure,

[0030] The connection between the piston head 1 and the piston rod 2 of the buffer piston is processed with a cylindrical buffer plunger A5 with an outer diameter larger than that of the piston rod, and the front end center of the piston head 1 extends forward from the cylindrical buffer plunger B6. The side walls of the buffer plunger at both ends of the piston head 1 are processed with oil inlet grooves gradually expanding from the piston head 1 to both sides.

[0031] The end of one end of the piston head of the check valve piston is processed with a spring installation groove. There are connected oil inlet holes;

[0032] The inner diameter of the cylinder barrel 3 matches the outer diameter of the piston head 1 in the buffer piston;

[0033] Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com