Device and method for measuring mass flow rate of solid particles in gas-solid two-phase flow

A solid particle and phase flow technology, applied in the field of measurement, can solve the problems that the measurement of the mass flow rate of solid powder cannot be completed, and the special properties of solid propellant powder are not applicable.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

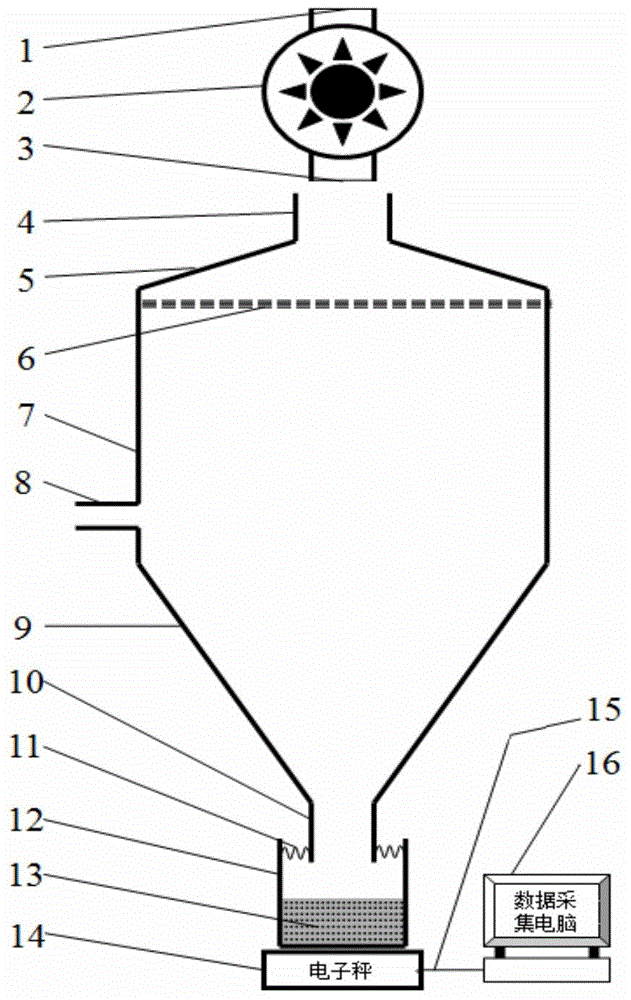

[0022] This embodiment is a device and method for measuring the mass flow rate of solid particles in a gas-solid two-phase flow.

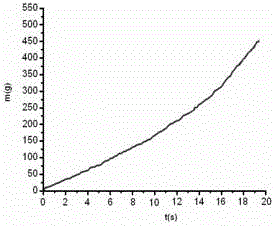

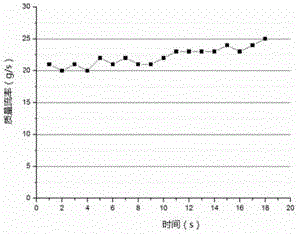

[0023] refer to figure 1 , figure 2 , image 3 , the mass flow rate measuring device of solid particles in the gas-solid two-phase flow of the present invention is composed of air extractor 2, cyclone separator, powder sieve net 6, support 20, powder accumulation cylinder 12, connecting sealing cover 11, electronic scale 14, data Line 15, data acquisition computer 16, flange 18, bolt 19, fixing hole 21, boss 22, air extractor 2 is installed on the upper end of the cyclone exhaust port, powder sieve net 6 is fixed in the cyclone In the upper part, the two-phase flow inlet 8 is located on the outer wall of the cylindrical section 7 of the cyclone separator. The bracket 20 is installed on the lower part of the cyclone separator and connected by bolts. It is connected with the data collection computer 16 through the data line 15; the connecting sea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com