Low-order torsional mode electromagnetic acoustic array transducer

A technology of array sensor and torsional mode, which is applied in the direction of ultrasonic/sonic/infrasonic generation to achieve high modal energy, uniform static magnetic field strength, and improved signal energy and signal-to-noise ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

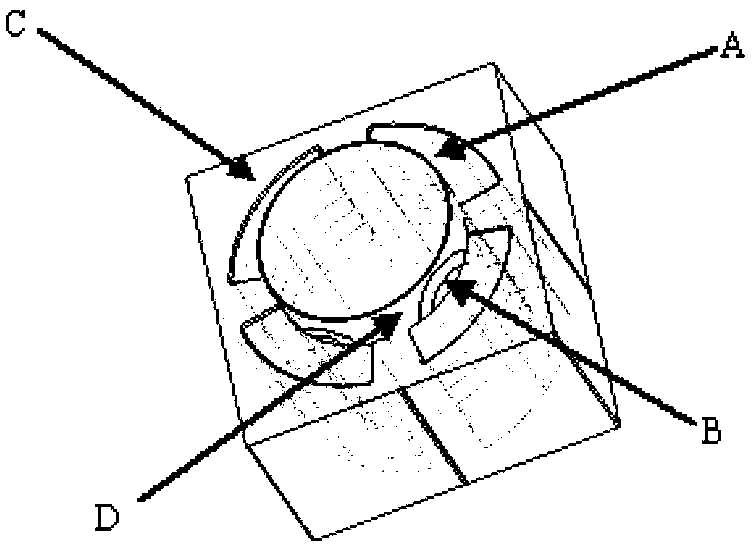

[0029] The device shown in the figure is used to achieve defect detection of alloy steel pipes.

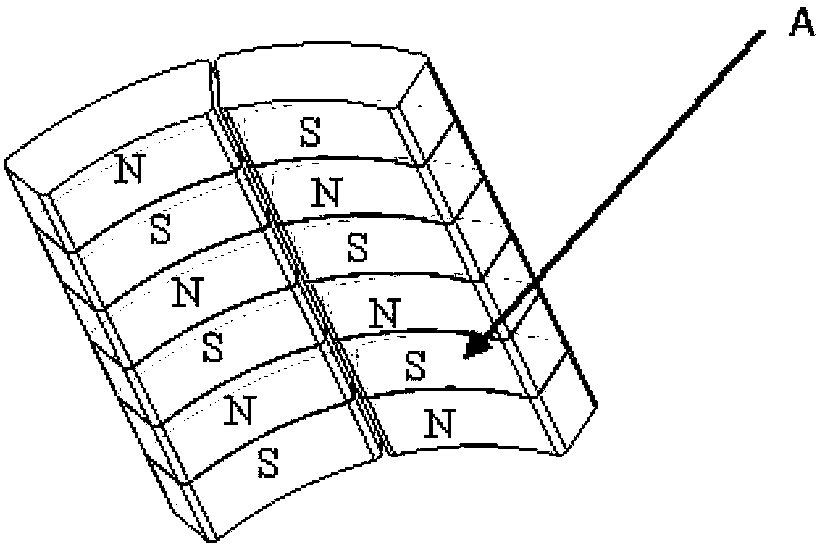

[0030] For defect detection of alloy steel pipes, the electromagnetic acoustic array sensor that excites the T(0,1) mode, A, rubidium iron boron magnet array, B, racetrack coil, C, PPM electromagnetic acoustic sensor housing, D, flexible printed circuit board, E. Electromagnetic acoustic array sensor, F, impedance matching network, G, RPR-4000 high-energy pulse transmitter / receiver, H, digital filter, I, computer, J, alloy steel pipe.

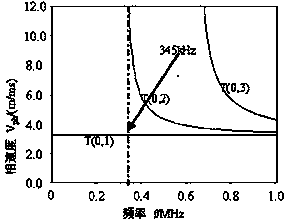

[0031] The alloy steel pipe J, the specification is 42×5×1000 (unit: mm), the material is 12Cr1MoV alloy steel pipe, the density is 7.85g / cm3, and the Poisson's ratio is 2.7. Image 6 The dispersion curve of the torsion mode in the alloy steel pipe is given in the above parameters. For testing other specifications and material pipes, the parameters of the electromagnetic acoustic array sensor can be adjusted accordingly according to this example.

[003...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com