Rolling tool

A rolling and tooling technology, which is applied in the direction of manufacturing tools, metal processing equipment, polishing machine tools, etc., can solve the problems of leaking fluid or emulsion, large rolling tools, loss, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

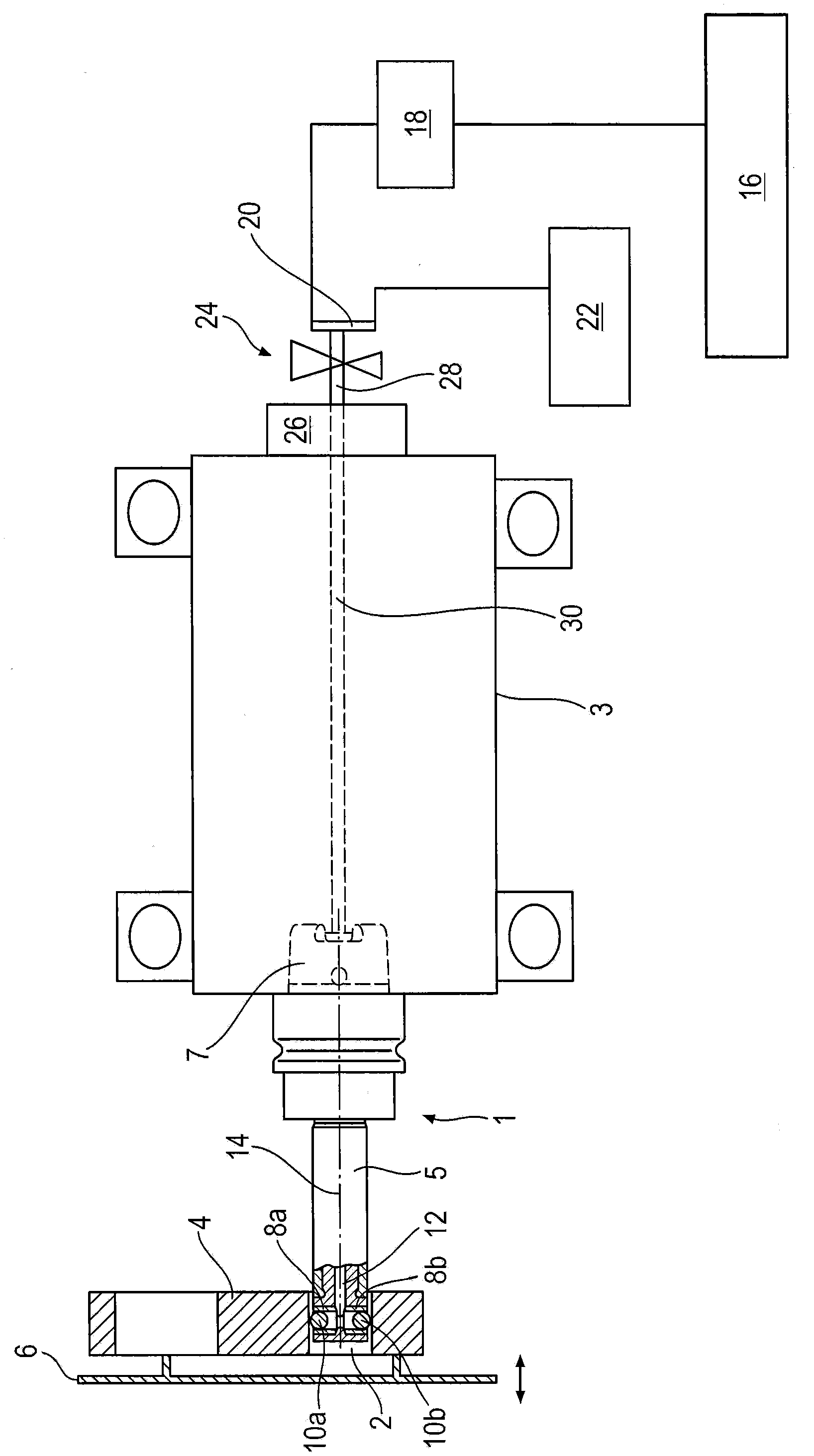

[0039] figure 1 A partial cross-sectional view and a partial schematic view of the rolling machine are shown. The rolling machine comprises a rolling tool 1 adapted to be driven in rotation relative to a stationary housing 3 .

[0040] A part 5 of the tool 1 is partially introduced into the connecting rod bore 2 of the connecting rod 4 . The connecting rod 4 is fixed to the receptacle 6 and is thus able to be displaced in translation relative to the tool 1 (according to the double arrow).

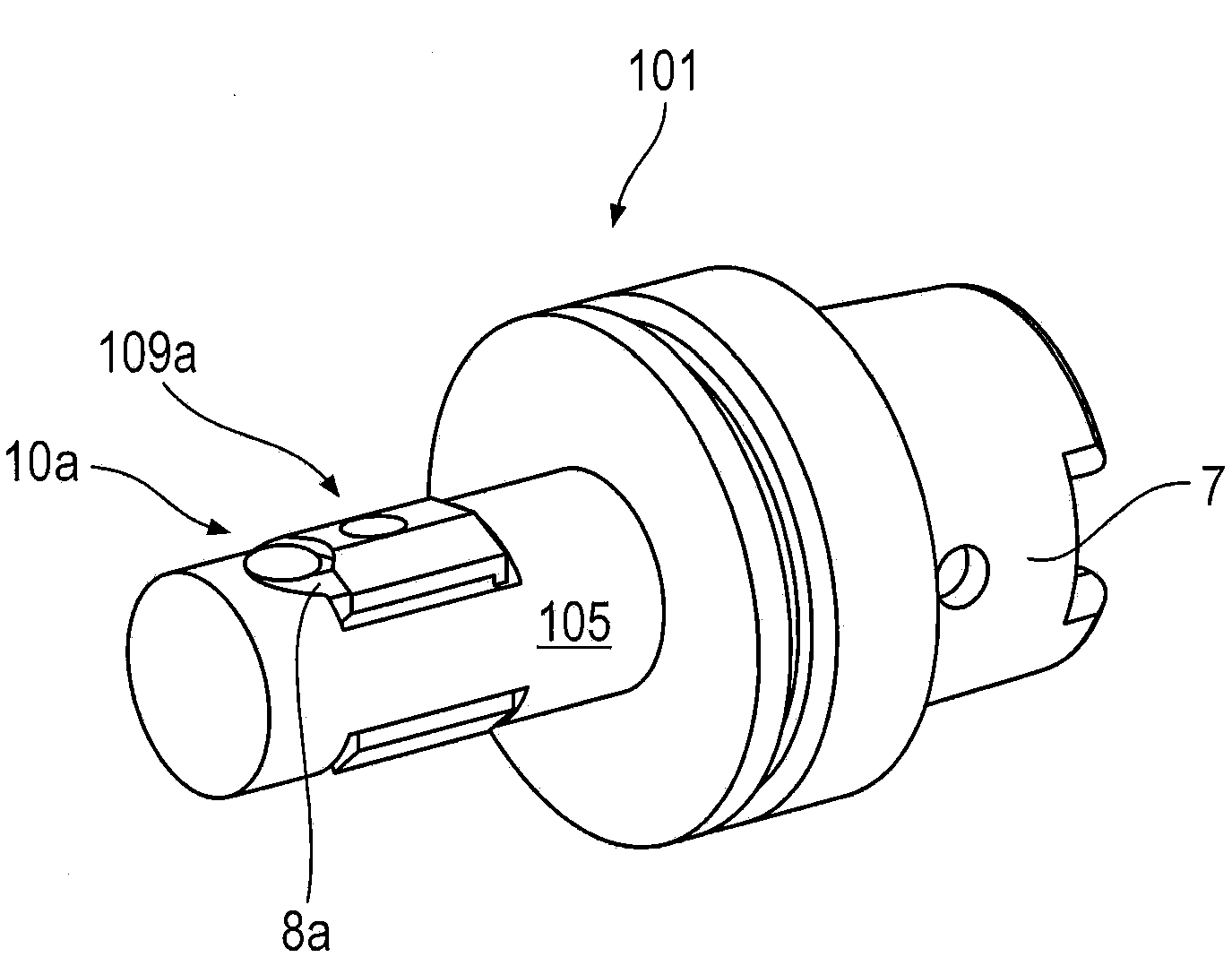

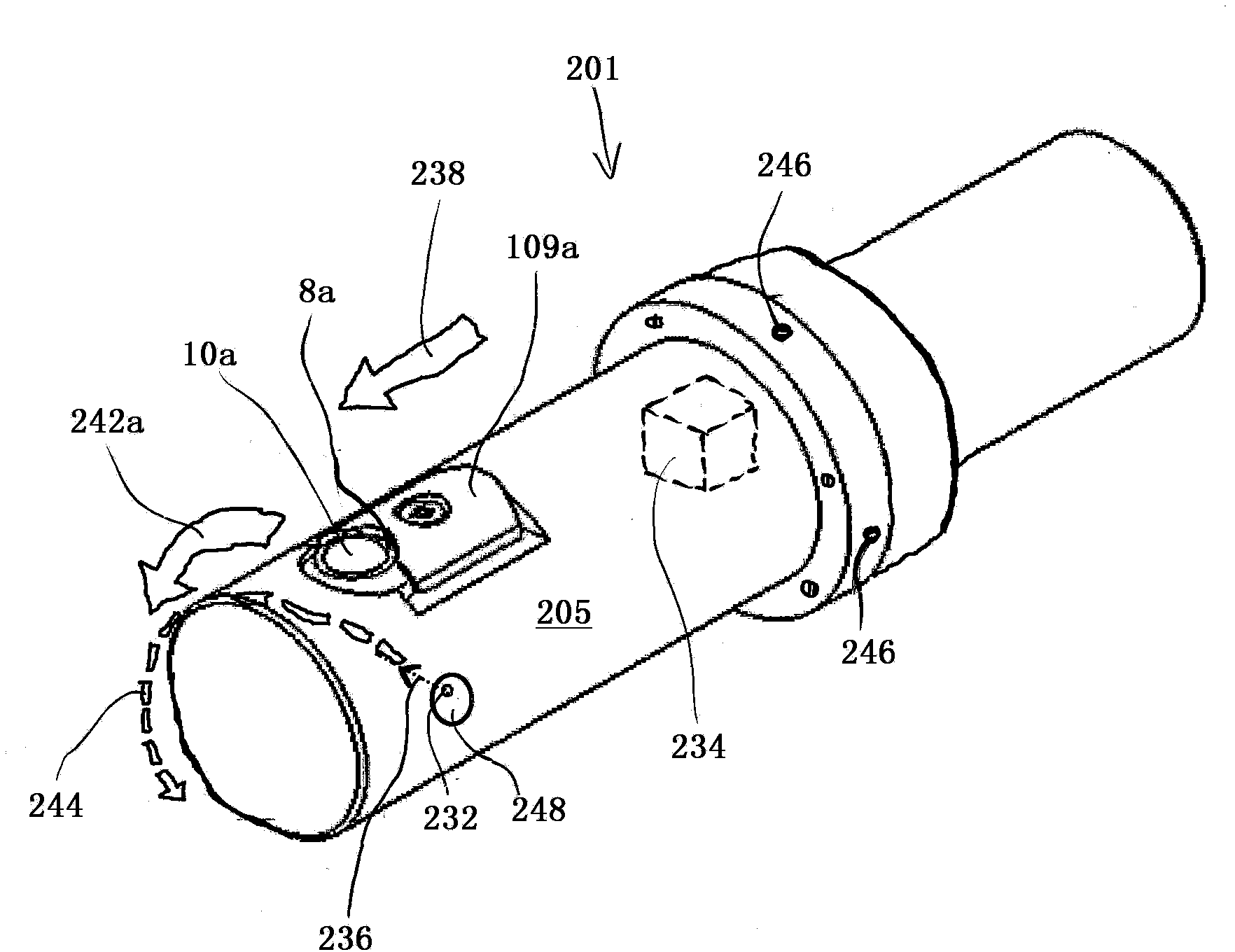

[0041] The part 5 of the tool 1 which is introduced into the connecting rod bore 2 is approximately cylindrical. Two radially extending opposite bushings 8 a , 8 b are inserted into the part 5 . At the radially outer end of part 5, a race is formed by a corresponding constraint (not in figure 1 shown in detail). The balls 10a, 10b are mainly housed in the bushings 8a, 8b, wherein the balls 10a, 10b basically have two different positions: In the unloaded position (not shown), the balls ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com