Process for producing ethylene/vinyl alcohol copolymer resin, ethylene/vinyl alcohol copolymer resin, and multilayer structure

A vinyl alcohol copolymer and vinyl ester copolymer technology, which is applied in the field of multilayer structures, can solve the problems such as the easy occurrence of gluing and quality deterioration of granular materials, and achieve the effects of excellent appearance characteristics, reduced yellowing, and suppression of quality deterioration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-2~1-7

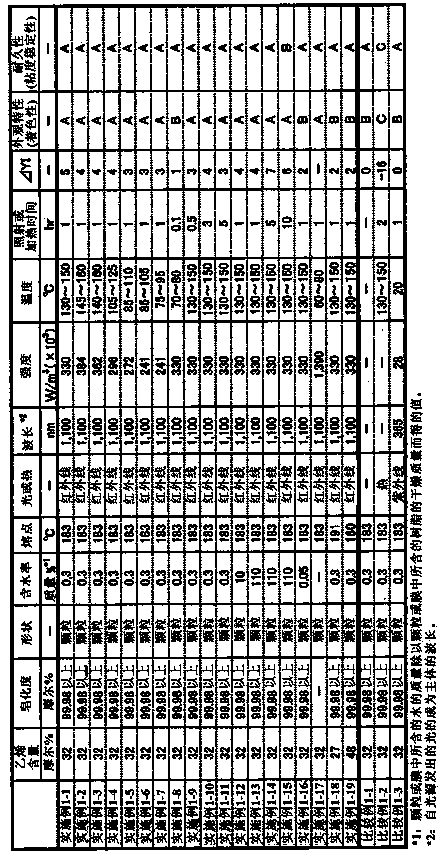

[0248] EVOH particles of Examples 1-2 to 1-7 were obtained in the same manner as in Example 1-1, except that the resin temperature and light intensity of the EVOH particles during infrared irradiation were as shown in Table 1.

Embodiment 1-8~1-11

[0250] EVOH particles of Examples 1-8 to 1-11 were obtained in the same manner as in Example 1-1 except that the resin temperature and infrared irradiation time for the EVOH particles during infrared irradiation were as shown in Table 1.

Embodiment 1-12

[0252] In Example 1-1, the EVOH pellets dried at 80° C. for 3 hours were taken out and the moisture content was measured. As a result, the moisture content was 10% by mass. The EVOH particles were irradiated with infrared rays in the same manner as in Example 1. Next, drying was performed at 120° C. for 24 hours by the same method as in Example 1-1 to obtain EVOH particles.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com