Industrial automatic quantitative liquid product production blending system

A liquid and product technology, applied in mixer accessories, chemical instruments and methods, mixers, etc., can solve problems such as poor labor environment, heavy physical strength, and low production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

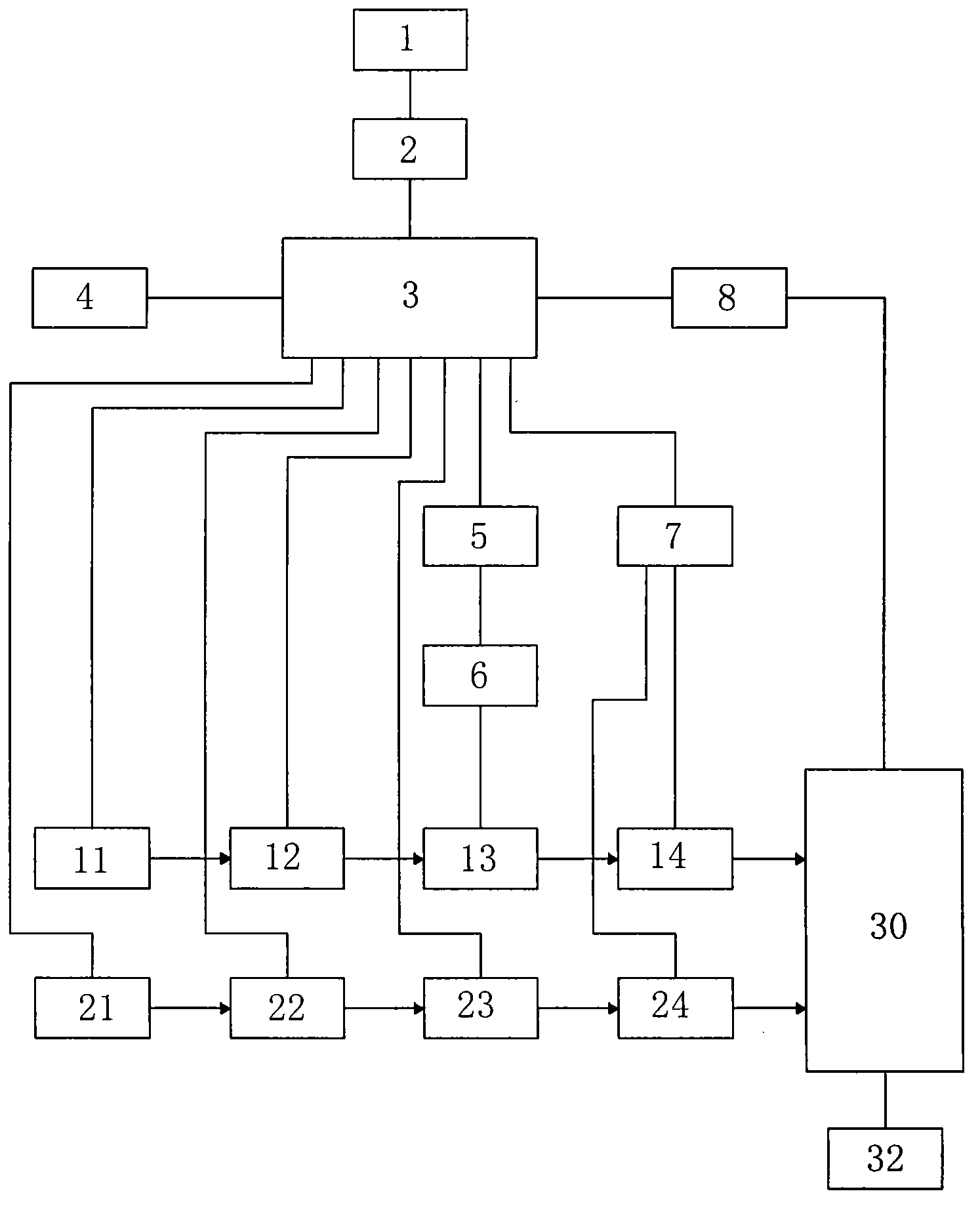

[0017] Embodiment Taking the methanol fuel automatic deployment system of FX2013-1018-1 of Shanxi Fengxi Energy Company as an example, take figure 1 The clues are explained as follows: From the perspective of long-term practicality, the upper computer adopts a highly reliable industrial computer, the single-chip MCU selects Siemens 200 industrial single-chip MCU, the solenoid valve selects GDLDSV2W-160-15, and the variable frequency pump selects stainless steel produced by Guangzhou Yongli Pump Industry Co., Ltd. Centrifugal pump, AOPU LR-6 for industrial frequency pump, intelligent turbine flowmeter LWYC-5 for flowmeter, TK6070K3WV touch screen for touch screen, 0.75KW EM235CN for inverter, CP2341 for Ethernet gateway, A, B, vertical drum reactor A 200-liter reactor is selected, and the C container is a sealed container resistant to corrosion, acid and alkali. In consideration of practical safety, the methanol fuel automatic dispensing system of FX2013-1018-1 has added emerge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com