Novel turning lathe

A lathe, a new type of technology, applied in metal processing equipment, tangent devices, manufacturing tools, etc., can solve problems such as product appearance and electrical performance, and achieve the effects of preventing cracks and rotten teeth, avoiding pollution, and improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in further detail below in conjunction with the accompanying drawings.

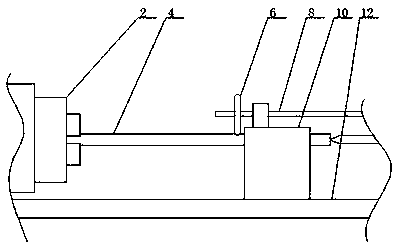

[0016] like figure 1 Shown, the present invention comprises the chuck 2 that is used for clamping workpiece 4, is provided with a slidable workbench 10 on the guide rail 12 of lathe, and emery wheel 6 is connected with the first power unit that drives it to rotate by transmission shaft 8, and transmission shaft 8 is connected on the workbench 10 by bearing. Transmission shaft 8 is adjustable in the position of feed direction. The chuck 2 is driven to rotate by the second power device. The first power unit is a high-speed motor, and the second power unit is a low-speed motor. The grinding wheel 6 is a diamond grinding wheel 6 .

[0017] The working principle of the present invention is as follows, at first adjust the position of emery wheel 6 feed direction, control the feed rate of emery wheel 6, then simultaneously drive first power unit and second power...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com