Process pipeline welding working station

A welding workstation and process pipeline technology, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of complex operation of automatic welding workstation, unsuitable for oil field station construction, and high operating cost, and achieve high welding efficiency. The effect of quality and welding efficiency, reduction of labor intensity and production cost, flexible and convenient disassembly

Active Publication Date: 2013-12-18

BC P INC CHINA NAT PETROLEUM CORP +1

View PDF8 Cites 3 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The present invention provides a process pipeline welding workstation, which overcomes the deficiencies of the prior art and can effectively solve the problems of the existing automatic welding workstations, which are complex in operation, equipped with many personnel, high in operating costs, and unsuitable for construction in oil field stations. question

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

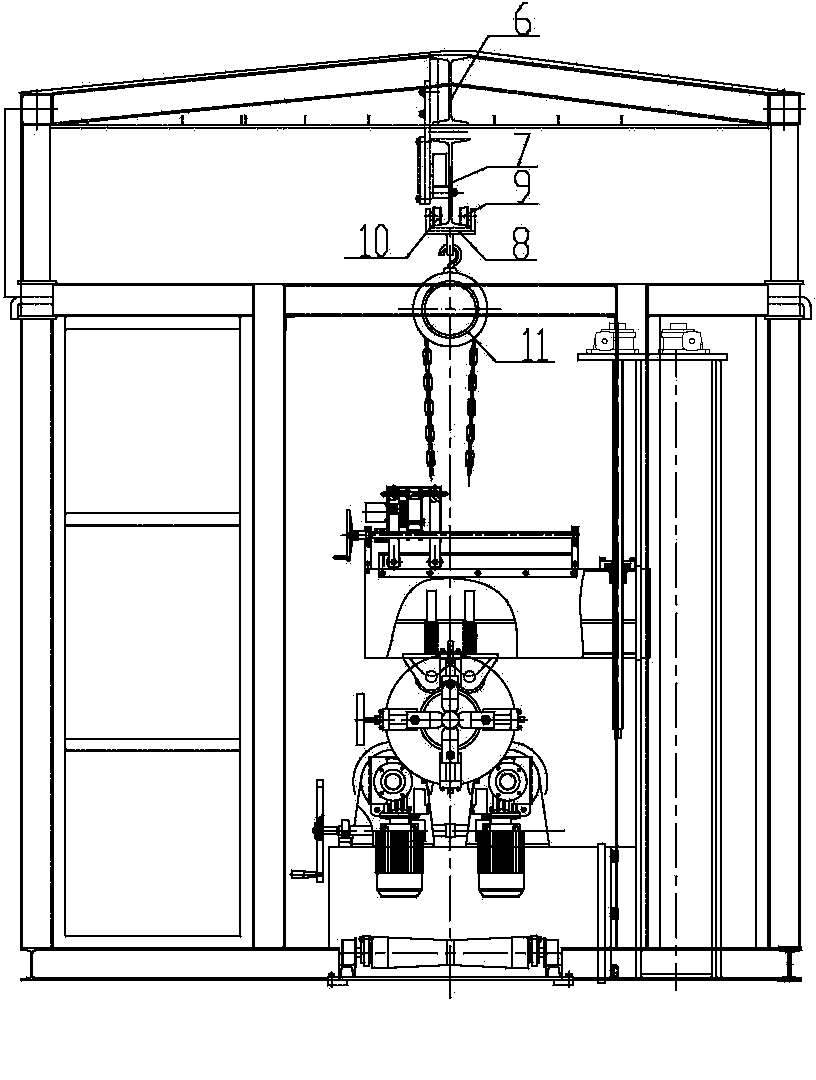

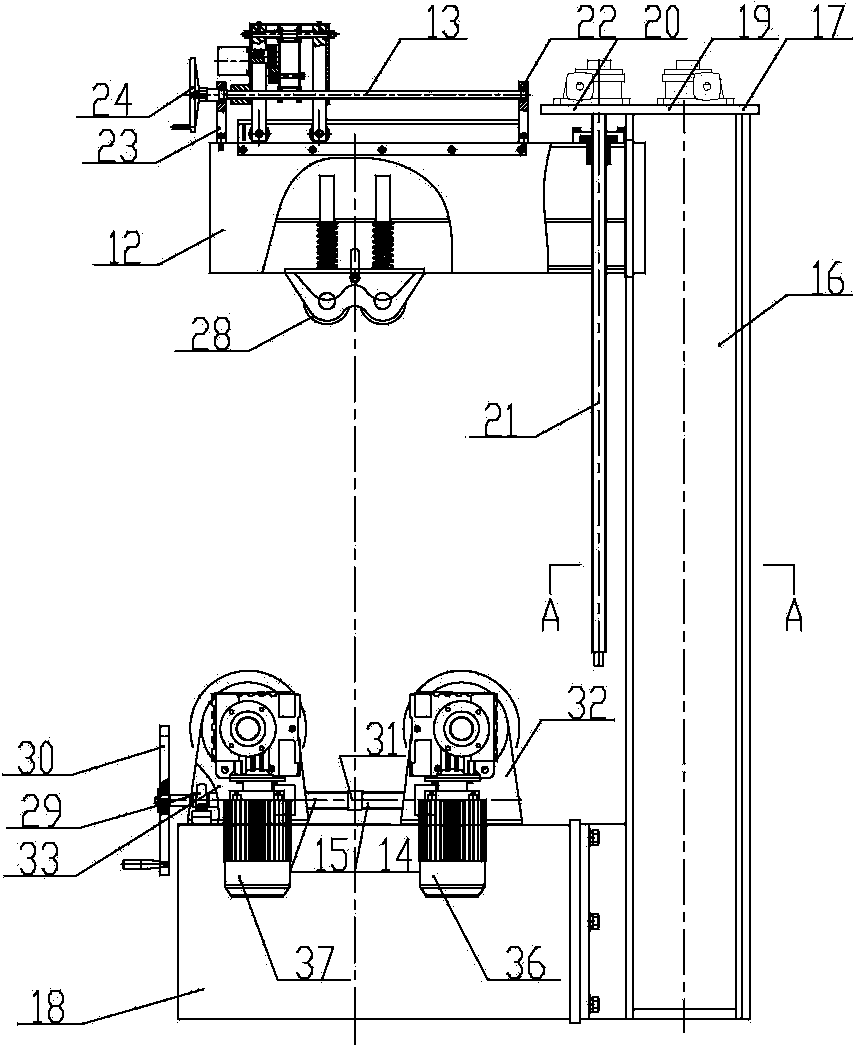

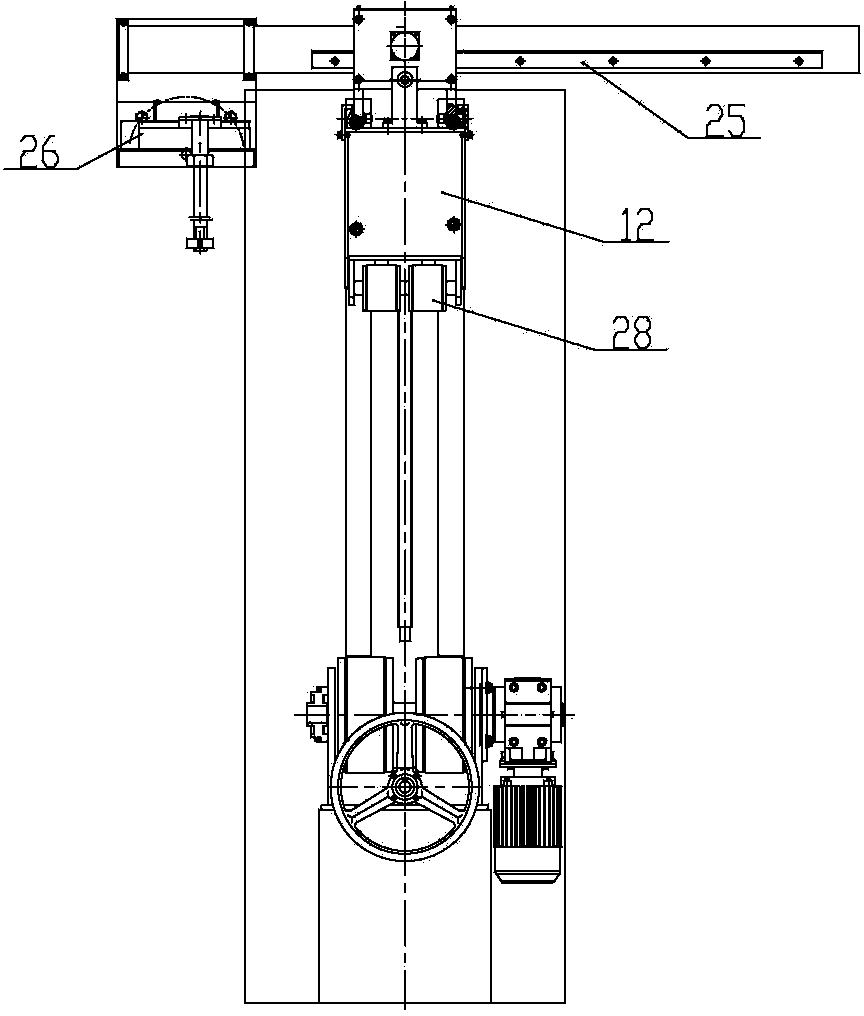

The invention relates to the technical field of an auxiliary device for pipeline welding, in particular to a process pipeline welding working station. The process pipeline welding working station comprises a horizontal track and a workshop, wherein the workshop is fixedly arranged on the middle part of the horizontal track; the left side and the right side of the workshop are provided with a material inlet and a material outlet which are communicated with the horizontal track respectively; the left part and the right part of the horizontal track are provided with a left bracket trolley and a right bracket trolley respectively; the horizontal track between the left bracket trolley and the right bracket trolley is provided with at least two conveying roller carriers; the upper part in the workshop is fixedly provided with a lifting device. The process pipeline welding working station has a rational and compact structure and is convenient to use; the purposes of transporting and lifting pipe fittings and welding between the pipe fittings are realized through cooperative use of the horizontal track, the workshop, a lifting, clamping and welding device and the lifting device; the process pipeline welding working station has the characteristics of flexibility and convenience in disassembly, safety and reliability, the operation is facilitated, the welding quality and the welding efficiency are improved, and the labor intensity and the production cost of operation personnel are reduced.

Description

technical field [0001] The invention relates to the technical field of pipeline welding auxiliary devices, and relates to a process pipeline welding workstation. Background technique [0002] In the current oil field surface construction, the process pipeline construction usually adopts the method of prefabrication in advance to reduce the number of welding joints in the later construction, thereby improving construction efficiency and shortening the construction period. At present, the prefabrication of process pipes mainly adopts two methods: manual welding prefabrication and automatic welding workstation prefabrication. The latter can improve welding efficiency, reduce labor intensity and improve welding quality. At present, the mode generally adopted by various types of automatic welding workstations in China is: firstly, the foreman is the counterpart, and after the welder makes the bottom, the crane or its own crane is used to lift it to the support, and transport it t...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): B23K37/00B23K37/04

Inventor 王志坚杨建强刘娅李原红卜庆风毛琦

Owner BC P INC CHINA NAT PETROLEUM CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com