Pattern printing device and pattern printing process thereof

A printing and station technology, applied in printing, printing machines, rotary printing machines, etc., can solve the problems of high printing cost, increased thickness, and many processes, and achieve the effect of fast printing speed, low production cost, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

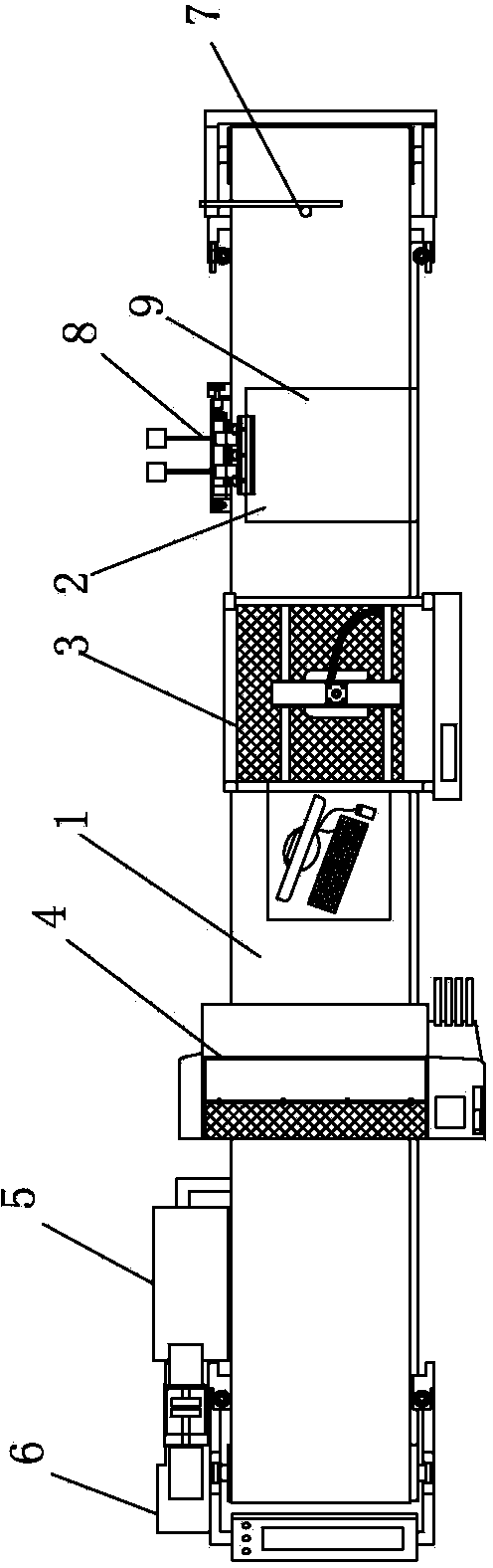

[0053] A printing device such as figure 1 shown, including

[0054] The hot-pressing printing mechanism 3 is used for heating the surface of the printing raw material;

[0055] The printing mechanism 4 is used to print patterns on the surface of the raw material after hot pressing and printing, and the printing mechanism 4 is arranged at the next station of the hot pressing and printing mechanism 3;

[0056] The workbench is used to supply materials to the hot-press unloading mechanism 3 and the printing mechanism 4, and to support raw materials.

[0057] With the printing device of the present invention, the hot-press printing mechanism 3 is used to fade the surface of the raw material into a white background color, and then the printing mechanism 4 is used to print patterns on the white background color, which solves the problem that traditional digital printing cannot print on dark-colored raw materials. There is no need to spray additional white background layer, which e...

Embodiment 2

[0060] A kind of printing device of the present invention, as figure 1 As shown, the main technical solutions of this embodiment are basically the same as those of Embodiment 1, and the features not explained in this embodiment are explained in Embodiment 1, and will not be repeated here. The difference between this embodiment and Embodiment 1 is that the workbench is set as a conveyor belt-type workbench.

[0061] The workbench includes a servo drive motor 5, a drive roller set 6 and a conveyor belt 1, the servo drive motor 5 is drivingly connected to the drive roller set 6, the conveyor belt 1 moves with the set, and the conveyor belt 1 passes through the heat transfer belt in turn. Press and pull printing mechanism 3 and printing mechanism 4.

[0062] The conveyor belt 1 can continuously pass the raw materials through the station without moving the raw materials, and the effect of plate alignment and color registration is good without displacement, and after laying the raw...

Embodiment 3

[0075] A kind of printing process of the present invention, comprises the steps:

[0076] Step 1, plate making, after making the pattern plate, apply fading agent on the position where the pattern is printed on the surface of the raw material according to the size of the pattern,

[0077] Step 2, unprinting, sending the raw material coated with the fading agent into the hot-pressing unprinting mechanism 3, hot-pressing unprinting, and unprinting the surface of the raw material into a white background color;

[0078] Step 3, printing, sending the raw materials after the printing is completed to the printing mechanism 4, and printing the pattern.

[0079] Step 4: Spray a color-fixing agent on the pattern surface after printing the raw material.

[0080] Using the printing process of the present invention, by applying the fading agent, the surface of the raw material is faded into a white background color through the hot-pressing printing mechanism 3, and then the printing mecha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com