Manufacturing method of tyre with colorful patterns and automatic production line of tyre with colorful patterns

An automatic production line, color pattern technology, applied in the post-processing of printing, printing device, printing and other directions, can solve the problems of high cost, complex process, low efficiency, etc., to achieve low production cost, low economic cost, high degree of automation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

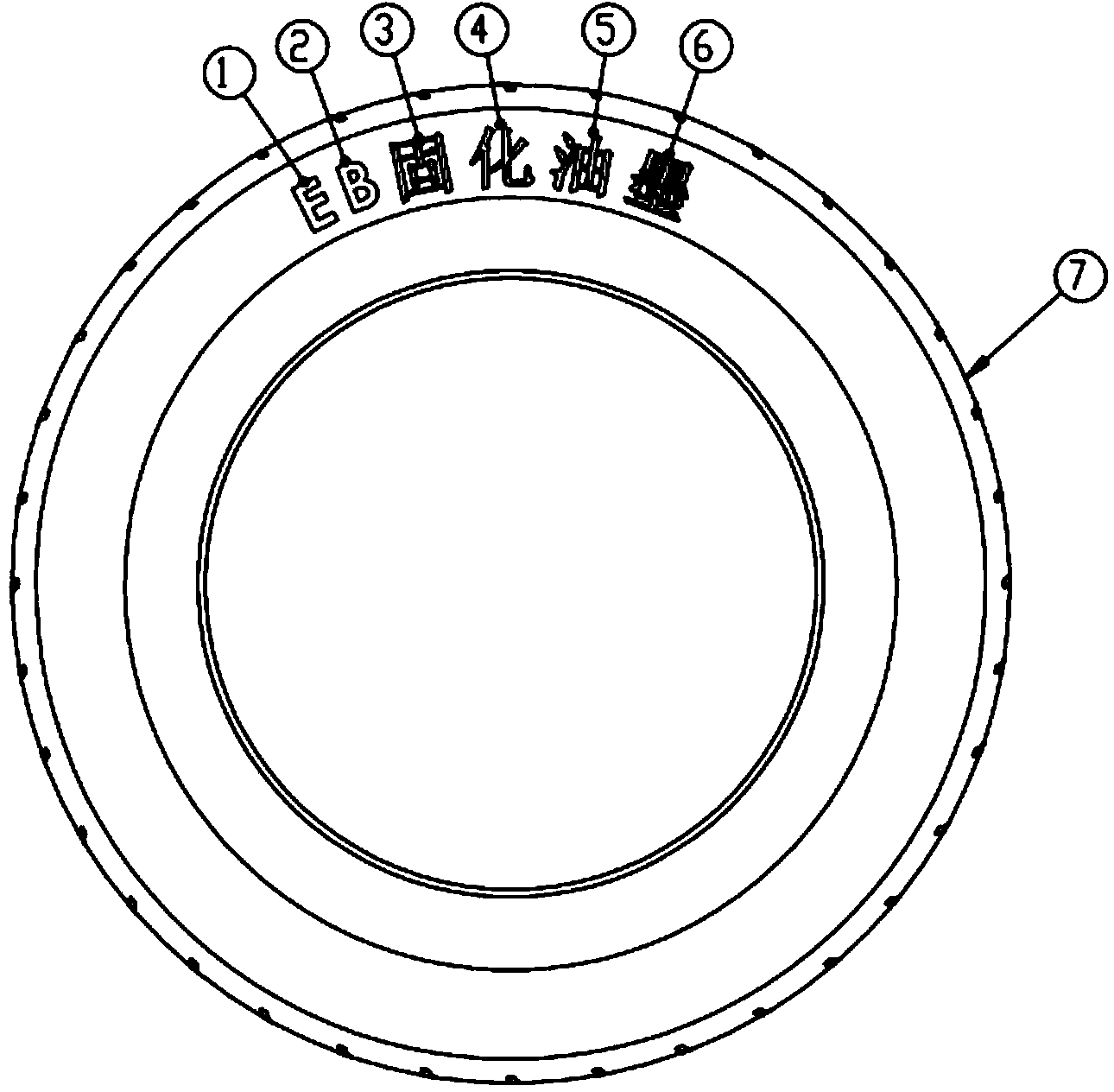

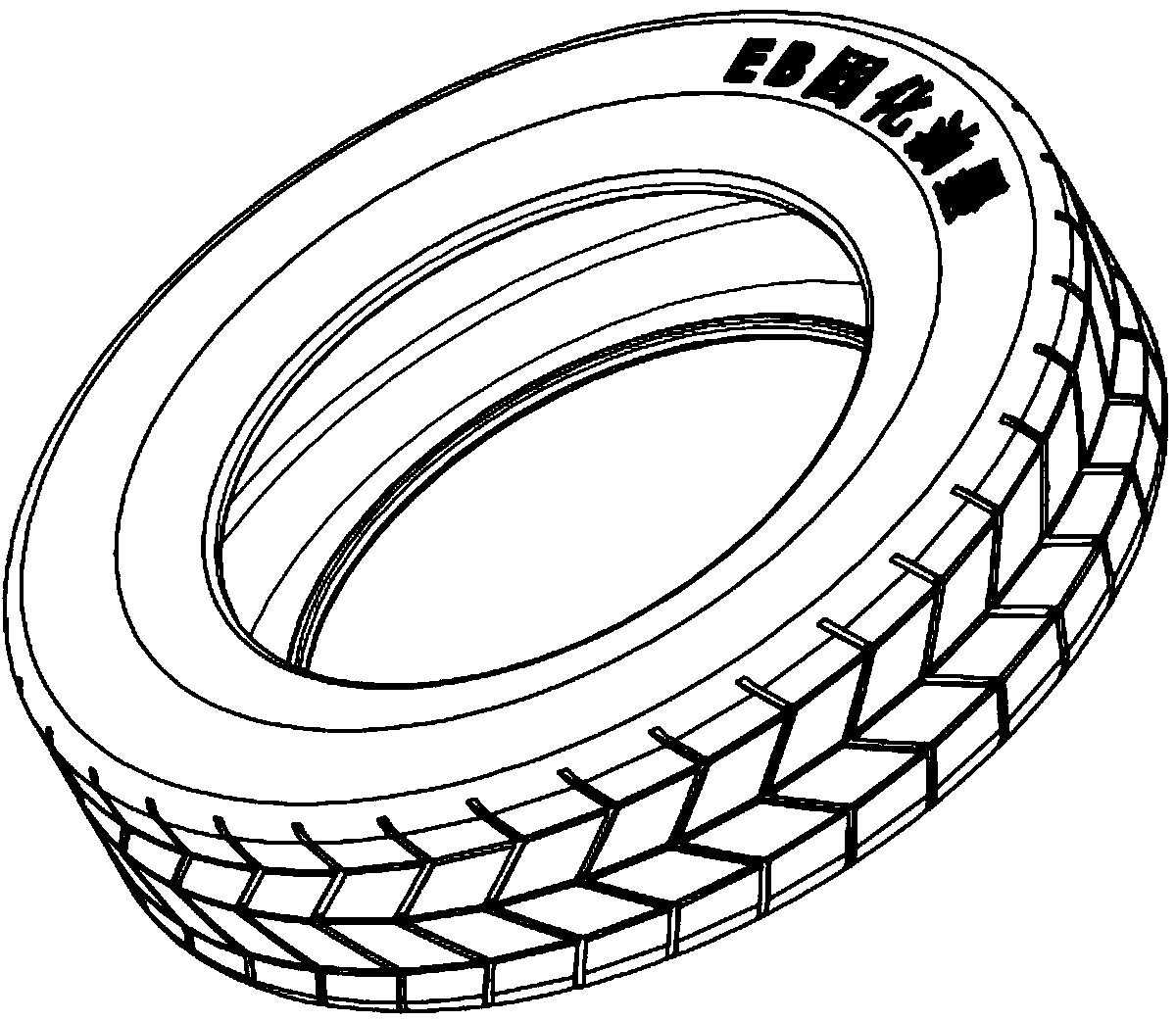

[0024] Such as figure 1 and 3 The specific embodiment of the tire with colored patterns produced by the present invention shown, figure 1 Among them, 1--red font, 2--orange font, 3--yellow font, 4--green font, 5--blue font, 6--purple font, 7, black carcass, ink can make various Different colors; spray patterns can be various characters, letters, patterns and patterns.

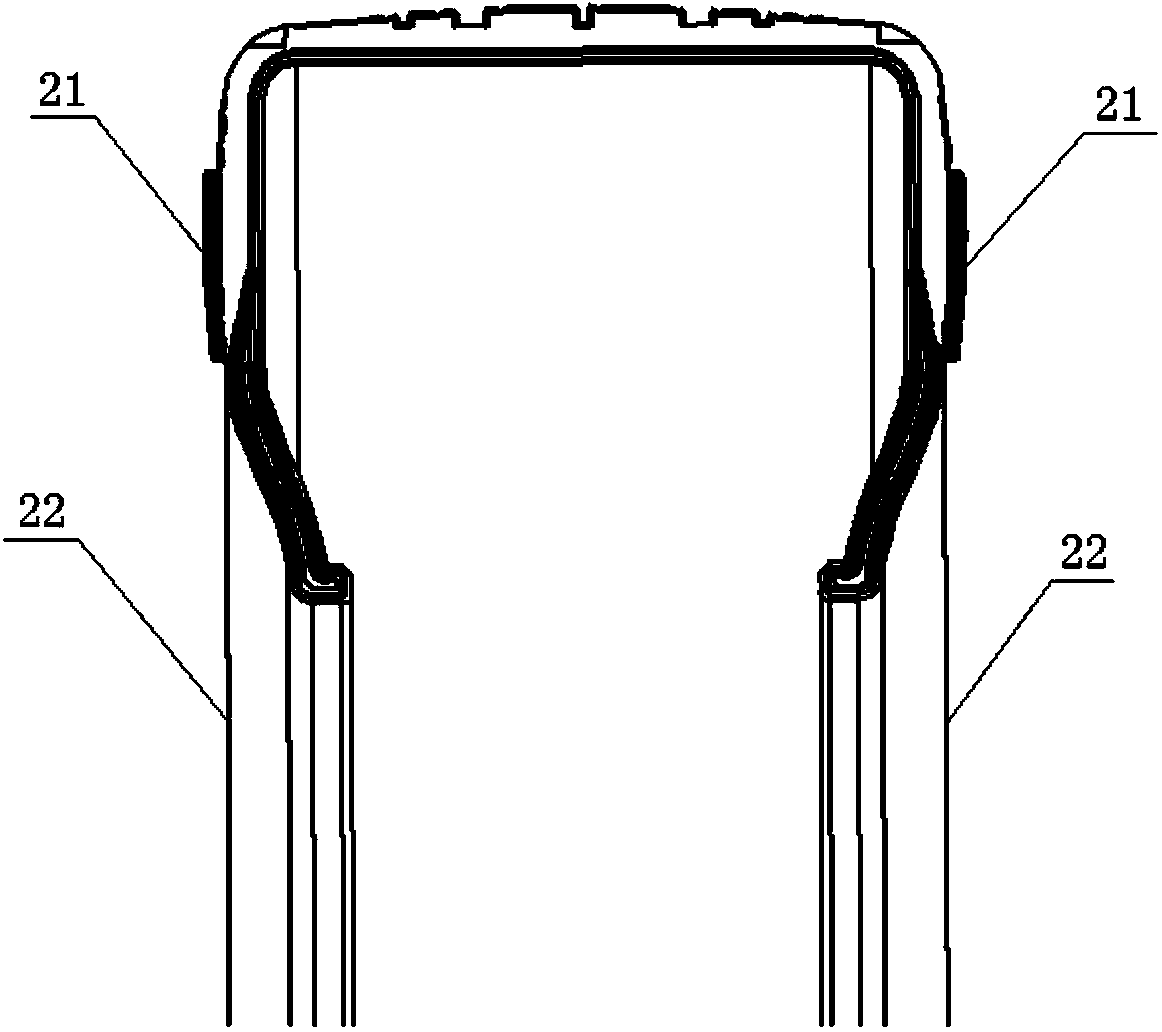

[0025] figure 2 Among them, 21 represents the place where the color ink is sprayed, and 22 indicates the side of the carcass.

[0026] Such as Figure 4 As shown, the production transmission line 15 runs through the first printing or spraying work area 11, the second printing or spraying work area 14, the turning device 13, the radiation curing work area 12 and the sorting equipment 16, the arrow along the production transmission line in the figure The direction is the transport direction of the tire 10 . The printing or spraying work area 11 is provided with a printing or spraying device, the radiation ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com