Tire containing non-Newtonian fluid

A non-Newtonian fluid and non-Newtonian technology, applied in the field of tires containing non-Newtonian fluids, can solve the problem of not being able to dynamically change the contact area between the tire and the ground, and achieve the effect of reducing the contact area, reducing tire resistance and increasing the contact area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

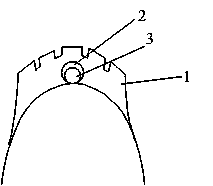

Image

Examples

Embodiment 1

[0019] The formula of the non-Newtonian fluid of the non-Newtonian fluid pipe related to the embodiment of the present invention is: 30 parts by weight of liquid polyvinyl alcohol, 5 parts by weight of fiber floc, 25 parts by weight of nanometer calcium carbonate, 15 parts by weight of heavy calcium carbonate, glass Brazing fiber is 25 parts by weight, and the thickness of the non-Newtonian fluid pipe is 15 millimeters.

Embodiment 2

[0021] The formula of the non-Newtonian fluid of the non-Newtonian fluid pipe related to the embodiment of the present invention is: 65 parts by weight of liquid polyvinyl alcohol, 5 parts by weight of fiber flocs, 15 parts by weight of nanometer calcium carbonate, 5 parts by weight of heavy calcium carbonate, glass 10 parts by weight of brazing fiber, and the thickness of the non-Newtonian fluid pipe is 5 mm.

Embodiment 3

[0023] The formula of the non-Newtonian fluid of the non-Newtonian fluid pipe related to the embodiment of the present invention is: 45 parts by weight of liquid polyvinyl alcohol, 5 parts by weight of fiber flocs, 20 parts by weight of nanometer calcium carbonate, 10 parts by weight of heavy calcium carbonate, glass Brazing fiber is 20 parts by weight, and the thickness of the non-Newtonian fluid pipe is 10 mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Cross section size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com