Ceramic tile furnishing equipment and method

A technology for ceramic tiles and equipment, applied in the field of ceramic tile manufacturing, can solve the problems of dull decorative effect of ceramic tiles, inability to combine decorative patterns, and no decorative effect, and achieve the effects of strong concave-convex feeling, low cost and convenient modification.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

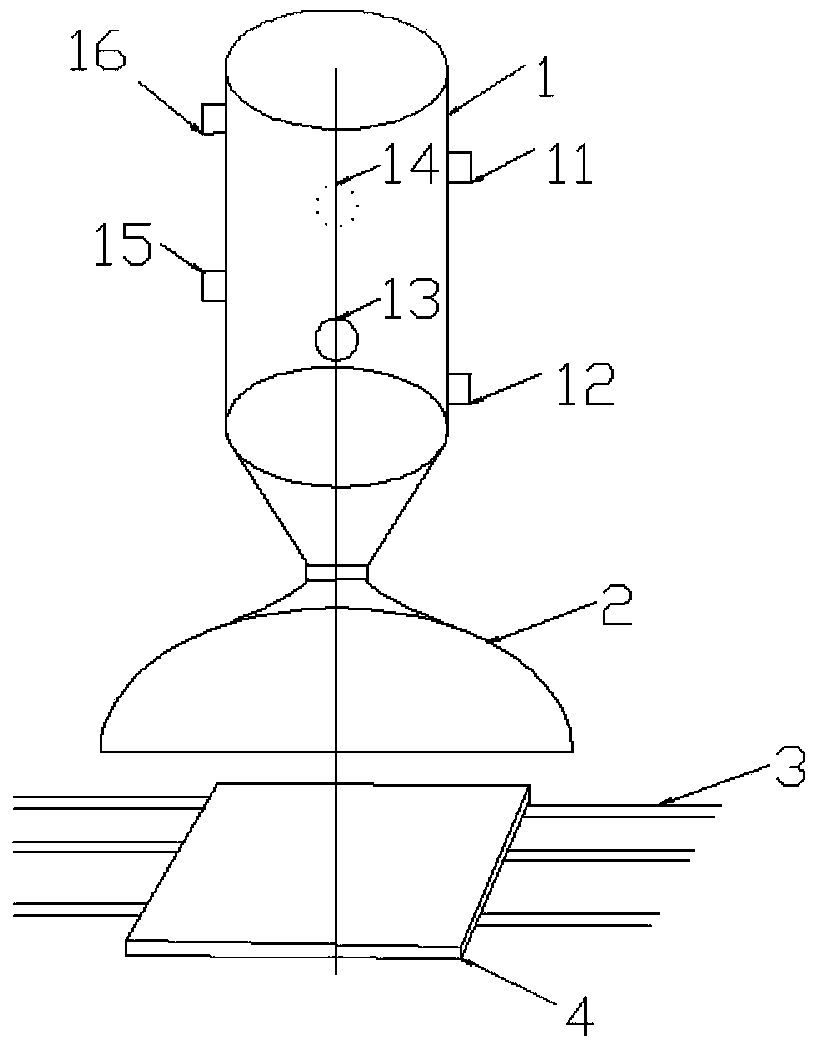

[0034] The ceramic tile decoration equipment of the present embodiment, such as figure 1 As shown, it includes a glaze mixer 1, a glaze bell jar 2, and a conveyor belt 3. The glaze glaze bell jar 2 is installed above the conveyor belt 3, and the lower end outlet of the glaze mixer 1 is connected to the glaze glaze mixer. The upper end entrance of bell jar 2.

[0035] The glaze mixer 1 is a container whose upper part is a cylinder and the lower part is a funnel. The upper part of the glaze mixer 1 has five glaze injection ports 11 , 12 , 13 , 14 and a glaze return port 16 .

[0036] The position of the glaze return opening 16 is higher than the glaze injection openings 11 , 12 , 13 , 14 , 15 .

[0037] The glaze injection openings 11, 12, 13, 14, 15 are evenly distributed on the upper, lower, left and right, front and rear parts of the cylinder.

[0038] The diameter to height ratio of the cylinder is 0.7.

[0039] The height ratio of the cylinder to the funnel was 1.2.

[...

Embodiment 2

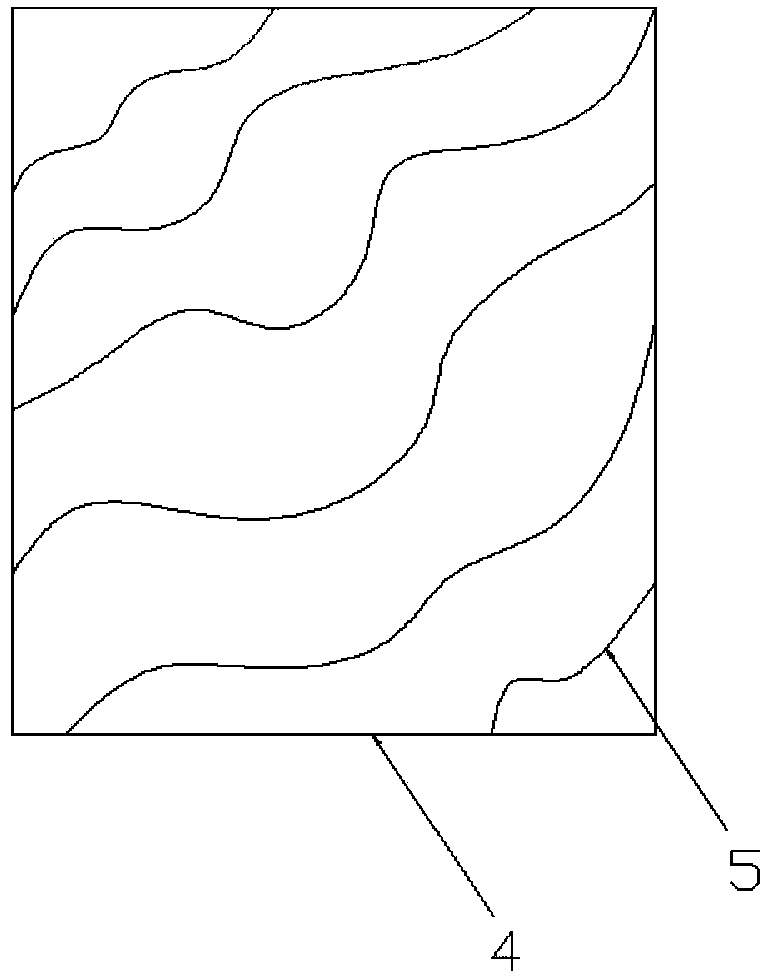

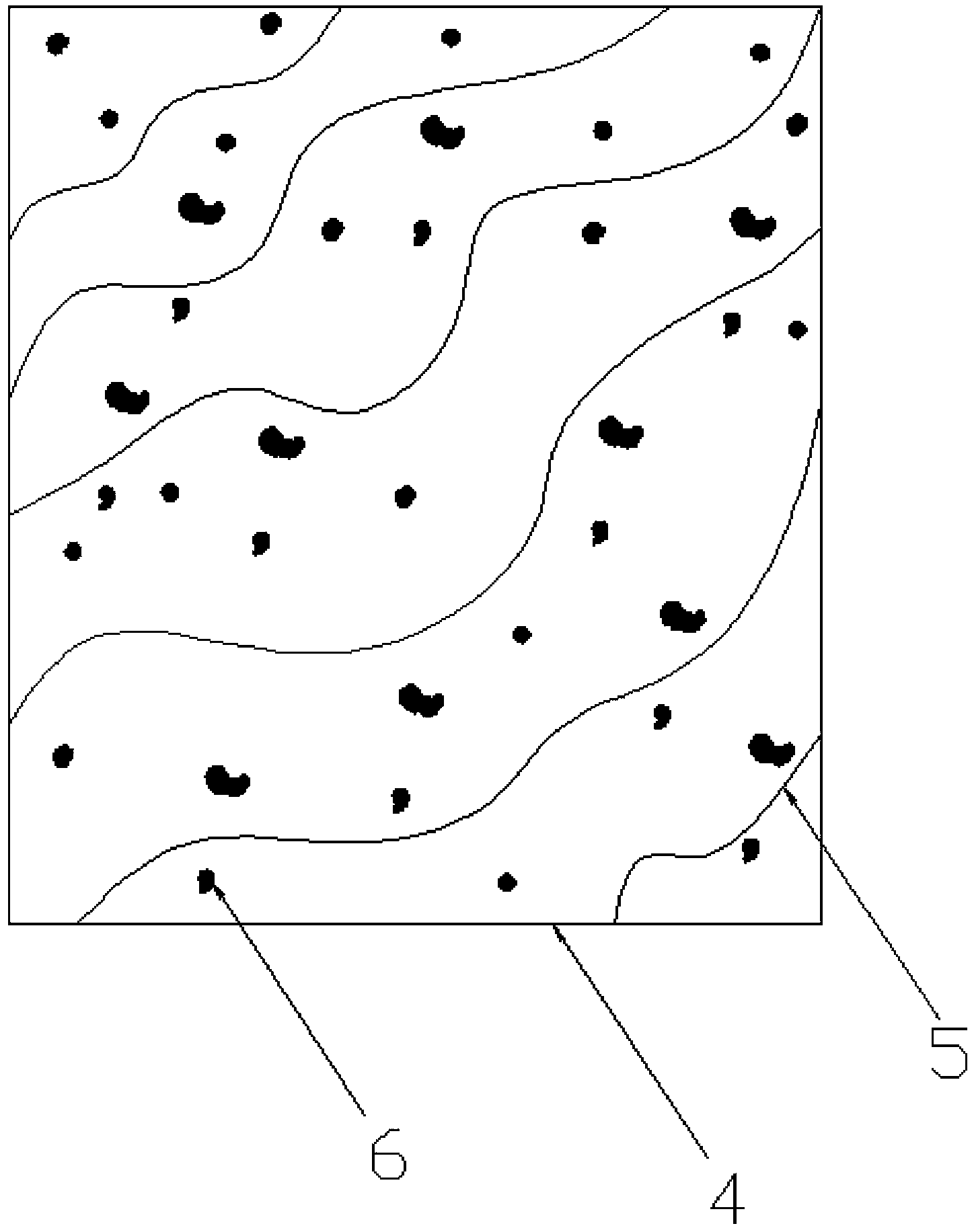

[0048] This embodiment is different from Embodiment 1, refer to figure 1 , figure 2 , image 3, using the above-mentioned ceramic tile decoration equipment, three sets of glaze mixing devices 1 and glaze pouring bell jars 2 are sequentially installed on the top of the conveyor belt 3 according to the conveying direction, and the grouting ports on the glaze mixing devices 1 of each group are respectively 4 , 5, 6. The ceramic tile body 4 passes through three sets of glaze bell jars 2 sequentially, and the glaze slurry is mixed in three different glaze mixers 1 to obtain different glaze slurry, and is sprayed on the ceramic tile body 4 by three sets of glaze glaze bell jars 2 to obtain glaze lines 5. Different glaze lines 5 that can be crossed (rotated at a certain angle in advance when passing through different ceramic tile decoration equipment) or stacked (each mixer uses different glazes, such as different colors), expand the use of the present invention The scope of appl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com