Stripping finishing method of woolen dyed fabric

A wool and fabric technology, applied in the field of stripping and finishing of wool dyed fabrics, can solve the problems of difficult stripping of wool reactive dyes and difficult stripping of wool reactive dyes, and achieve excellent stripping effect, high dyeing consistency, The effect of high color rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

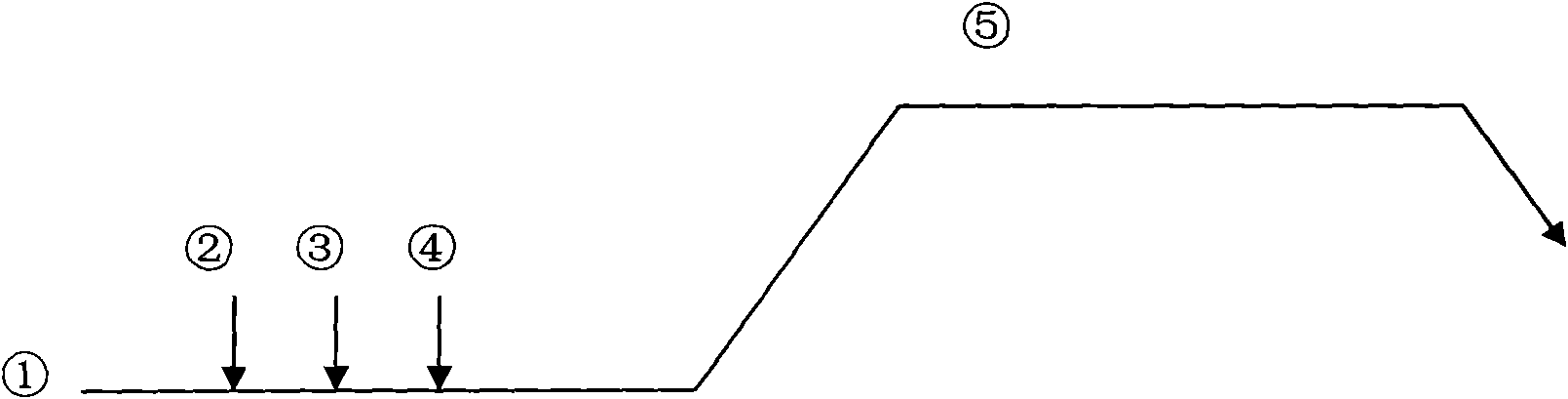

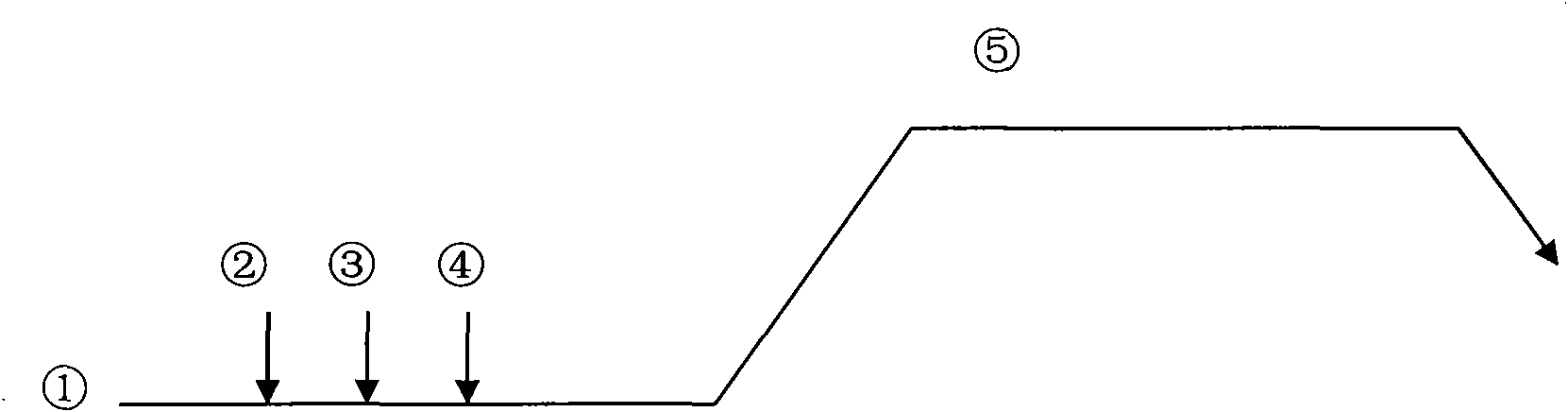

Method used

Image

Examples

Embodiment 1

[0023] Embodiment 1 (wool bulk fiber)

[0024] Select 170 kg of wool dyed loose fiber (the original red dyeing formula dosage is about 4%), put it into a solution with a liquor ratio of 1:20 at room temperature, add leveling agent ALBEGAL SET 3%, and add a reducing agent after running for 5 minutes Degulin 2%, adjust the pH value to 4.5-5.5 with formic acid, raise the temperature to 90°C and keep it warm for 30 minutes, slowly cool down to 60°C, wash it with water, and then dye it after 2 washes. After stripping, use a DATACOLOR SF600 spectrophotometer to test the K / S value, and the stripping rate is 72%.

Embodiment 2

[0025] Embodiment 2 (wool yarn)

[0026] Select 100 kg of wool dyed yarn (the amount of the original green dyeing formula is about 3%), put it into a solution with a bath ratio of 1:20 at room temperature, add leveling agent ALBEGAL SET 4%, run for 15 minutes and then add reducing agent Degulin 3%, use formic acid to adjust the pH value to 4.5-5.5, raise the temperature to 95°C and keep it warm for 30 minutes, after slowly cooling down to 60°C, wash it with water, and then dye it after 3 washes. The K / S value was tested with a DATACOLOR SF600 spectrophotometer, and the stripping rate was 60%.

Embodiment 3

[0027] Embodiment 3 (wool gray cloth fabric)

[0028] Select 200 kg of wool dyed gray fabric (the original black dyeing formula dosage is about 6%), put it into a solution with a bath ratio of 1:10 at room temperature, add leveling agent ALBEGAL SET 4%, run for 5 minutes, add reducing agent Degu Lin 2%, adjust the pH value to 4.5-6 with formic acid, heat up to 90 degrees and keep warm for 20 minutes, slowly cool down to 60 degrees, wash with water, and dye after 2 washes. The K / S value was tested with a DATACOLOR SF600 spectrophotometer, and the stripping rate was 78%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com