Method for producing profile for aircraft wing stringers

A wing and truss technology, applied in the field of producing aircraft wing truss profiles, can solve problems such as product yield and stability, and achieve the effects of improving surface quality, reducing defects in coarse crystal rings, and improving overall performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Next, preferred embodiments of the present invention will be specifically described. It should be understood that those skilled in the related art may make various equivalent transformations to the details of the disclosed implementations, and these equivalent transformations are also within the protection scope of the present invention.

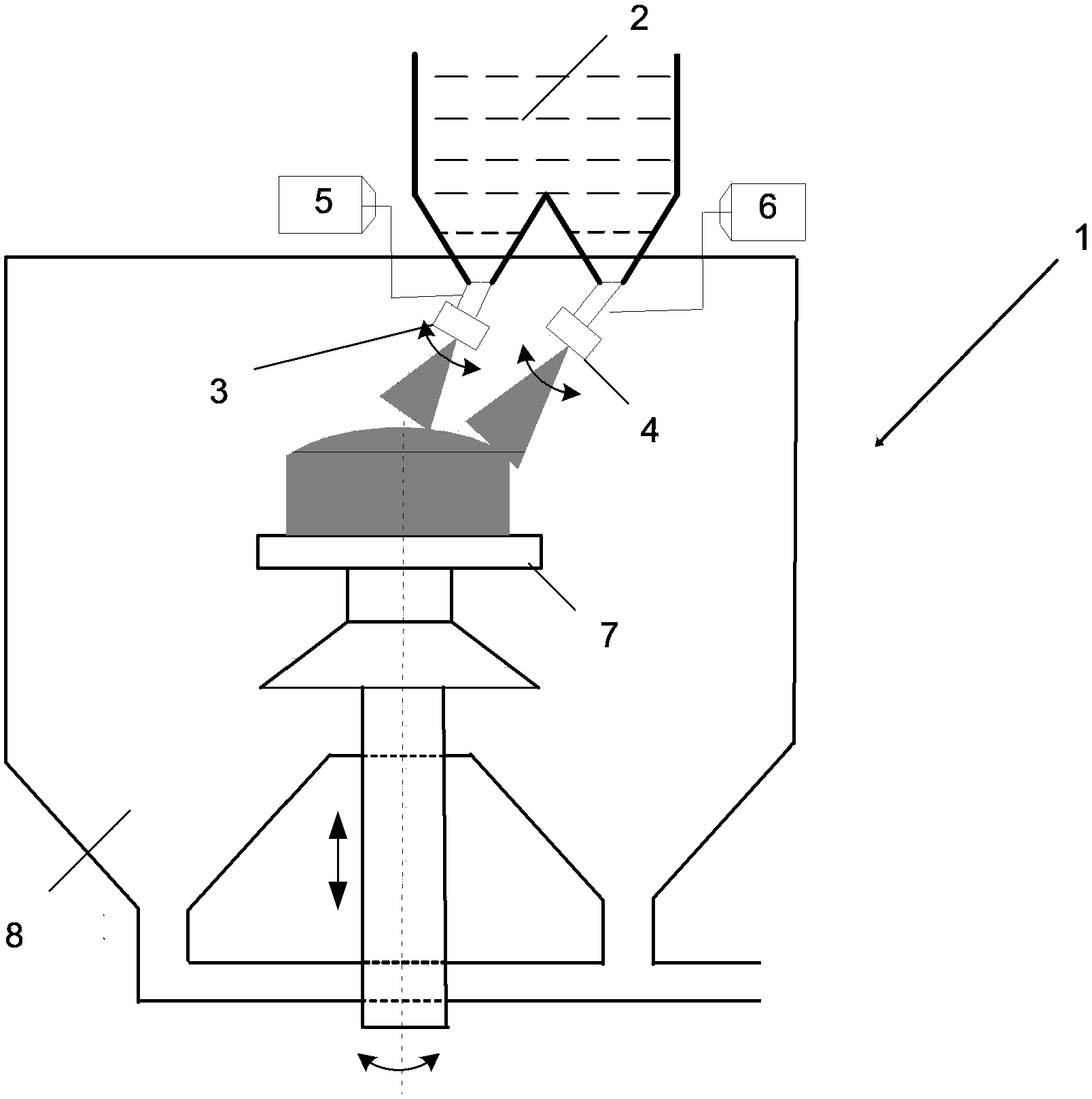

[0028] Next, the method for producing the aircraft wing stringer profile of the present invention will be specifically described.

[0029]

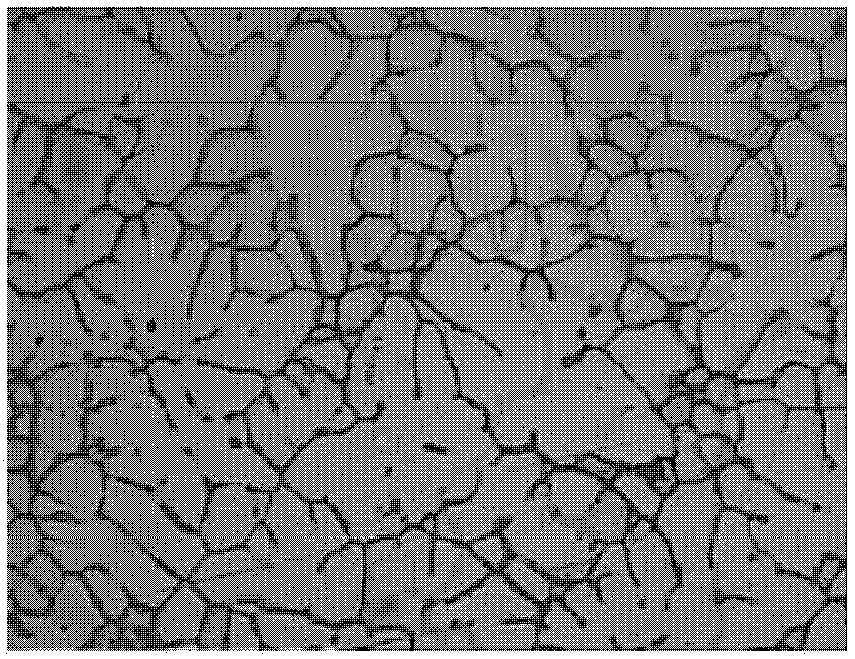

[0030] First, calculate the amount of aluminum ingots, intermediate alloys, and pure metal alloys according to the optimization and adjustment plan of the aluminum alloy composition, and melt the raw materials in a furnace such as an intermediate frequency furnace. Among them, the calculation of the composition of the aluminum alloy is calculated based on the data of the composition of the 7055 aluminum alloy. The composition of the 7055 aluminum alloy used in the present invention is specific...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com