Prestressed Loading Device of Internal Support System of Foundation Pit Support

A support system and foundation pit support technology, which is applied in basic structure engineering, excavation, construction, etc., can solve the problems of non-reusable, low support stiffness, and difficult to control deformation, so as to save construction costs, large construction space, The effect of convenient construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

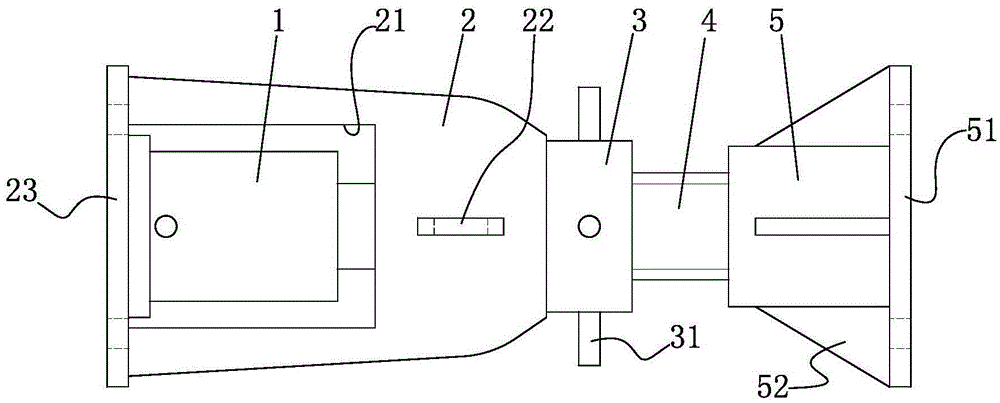

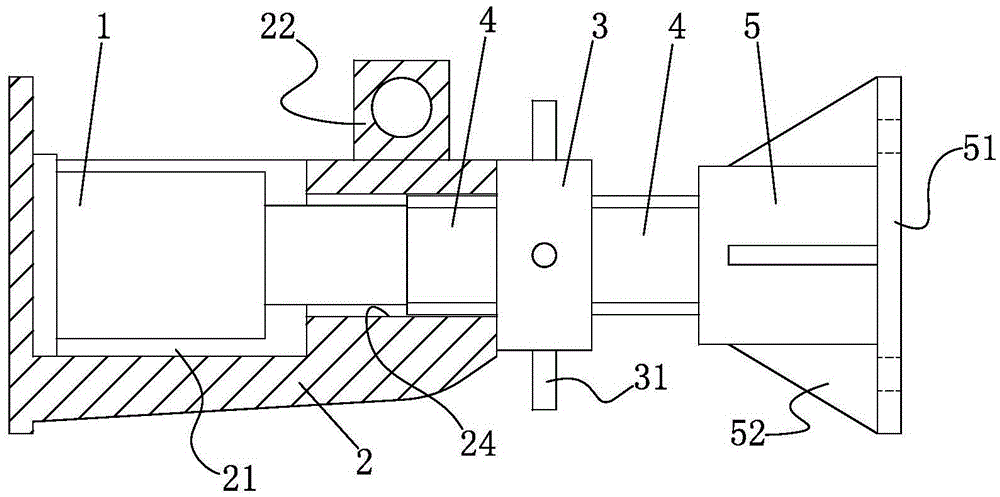

[0017] like figure 1 , figure 2 The prestressed loading device of the inner support system of the foundation pit support includes a jack 1 and a connecting part, and the connecting part includes a loading seat 2, a nut 3, a screw 4 and a screw base 5, and the loading seat 2 is provided for placing The groove 21 of the jack 1, one side of the groove 21 is a screw socket 24, the screw 4 is inserted in the screw socket 24, and the loading seat 2 is provided with a connecting flange A23 on the opposite side of the screw socket 24, and the groove 21 The jack 1 is placed inside, the top strut of the jack 1 is inserted into the screw socket 24 and is offset against one end of the screw 4, and the other end of the screw 4 is fixedly connected with the screw base 5, and the screw base 5 is provided with a connection on the opposite side of the connecting screw 4. The flange B51 and the nut 3 capable of abutting against the loading seat 2 are threadedly connected to the part of the sc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com