Scratch nail structure for fixing fire resistant materials for boiler

A technology for refractory materials and nails, applied in the combustion method, combustion chamber, cover/lining and other directions, can solve the problems of refractory material falling off, weld cracking, affecting the safety and reliability of boilers, etc., to achieve reliable connection and improve safety and reliability. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

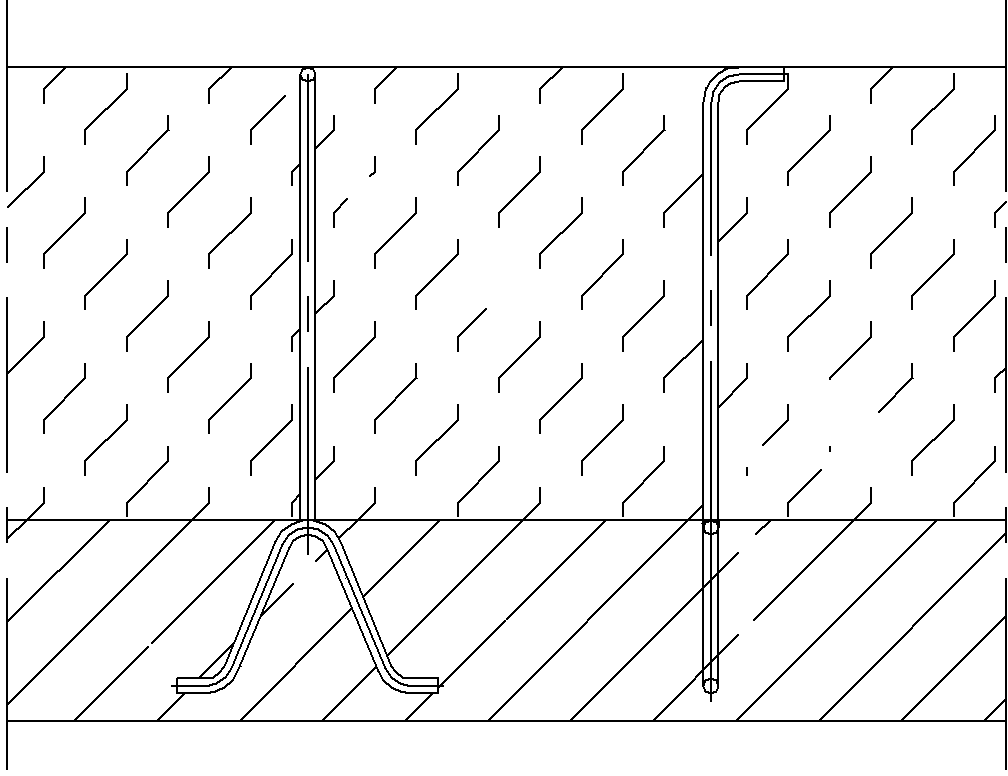

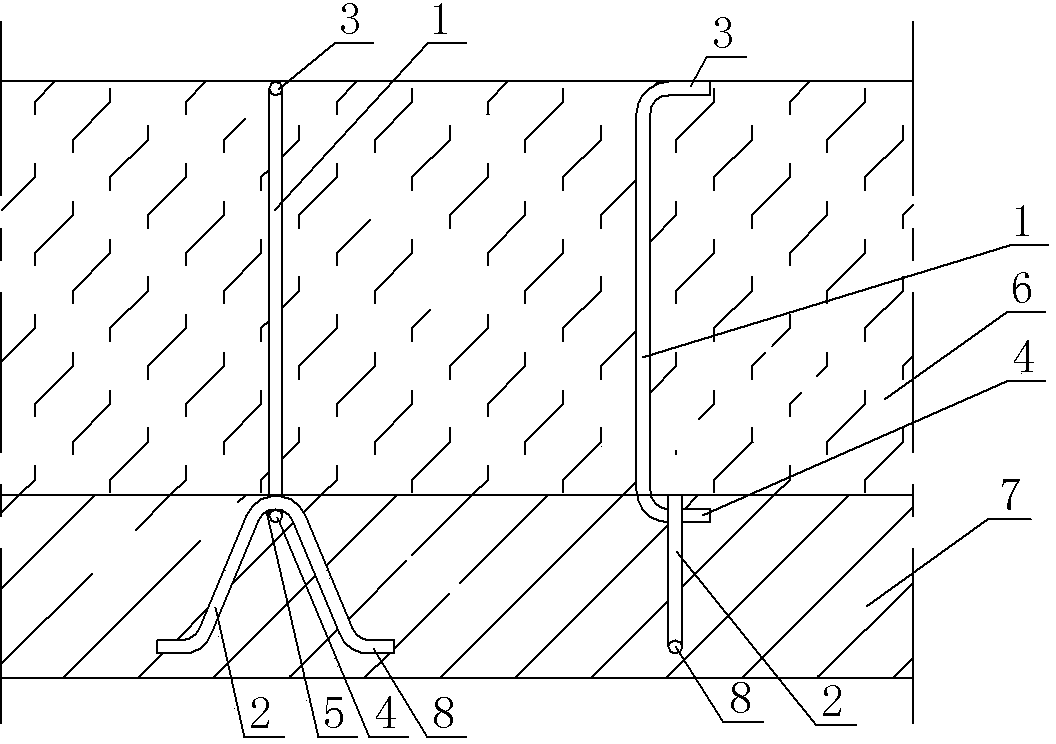

[0008] See figure 2 , which includes a tail structure 1, a head structure 2, the upper part of the tail structure 1 protrudes 3, the head structure 2 is an angled outward flaring structure, the lower part of the tail structure 1 has an outer convex hook 4, and the outer convex hook Hook 4 to catch the bending position 5 at the lower part of the center of the outwardly flared structure with an angle, and then weld and connect. In the figure, 6 is an insulating material layer, and 7 is a refractory material layer. The upper protruding part 3 of the tail structure 1 of the grab nail hooks the insulation material layer 6, and the outward flared part 8 of the angled outward flare structure of the head structure of the grab nail hooks the refractory material layer 7.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com