Method and device for measuring accurate contents of core components of liquid beverage in situ in production process

A technology for on-site measurement and production process, which is applied in the directions of measuring devices, color/spectral characteristic measurement, and material analysis, etc. It can solve problems such as complex operation, poor accuracy and uncertainty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

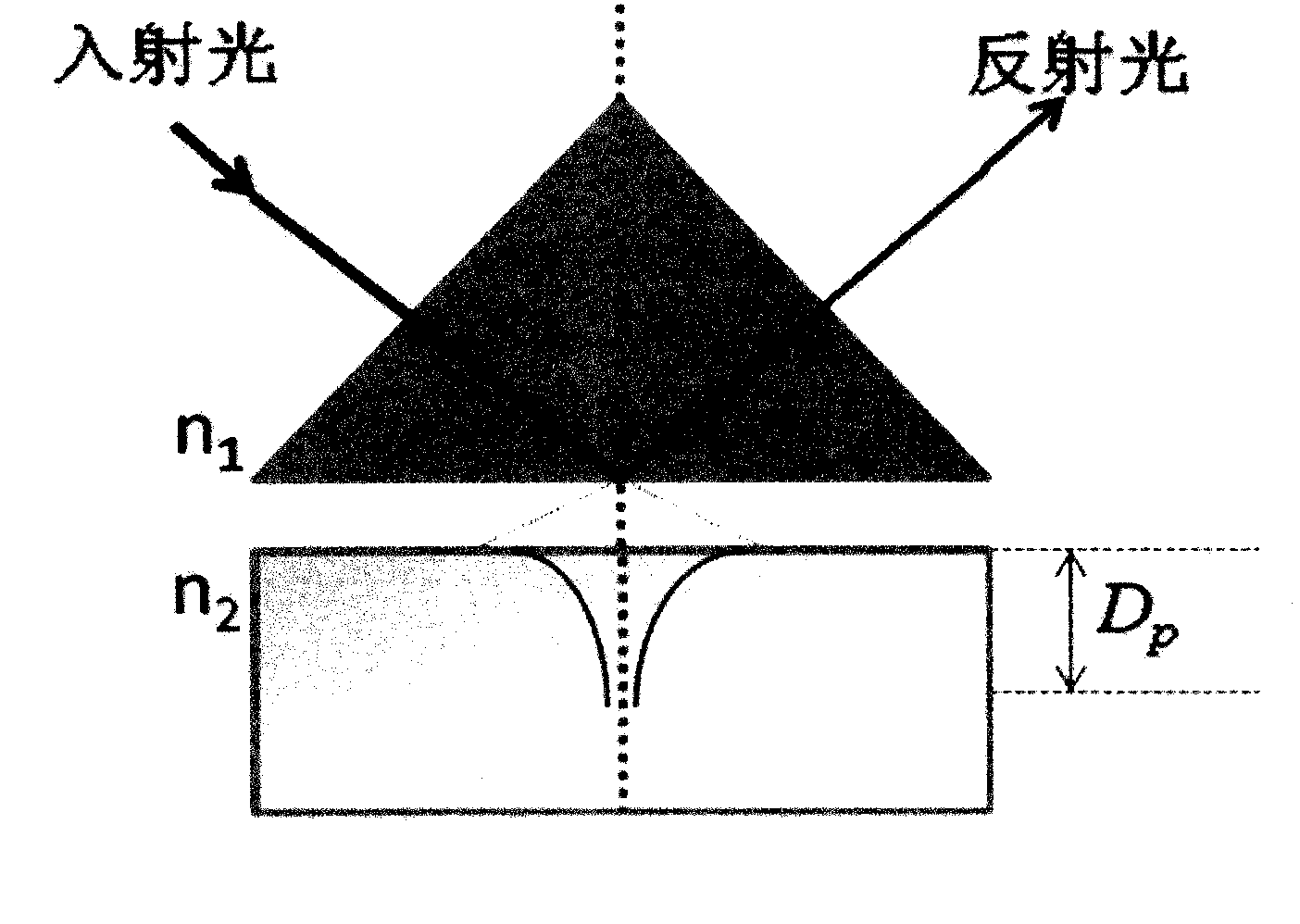

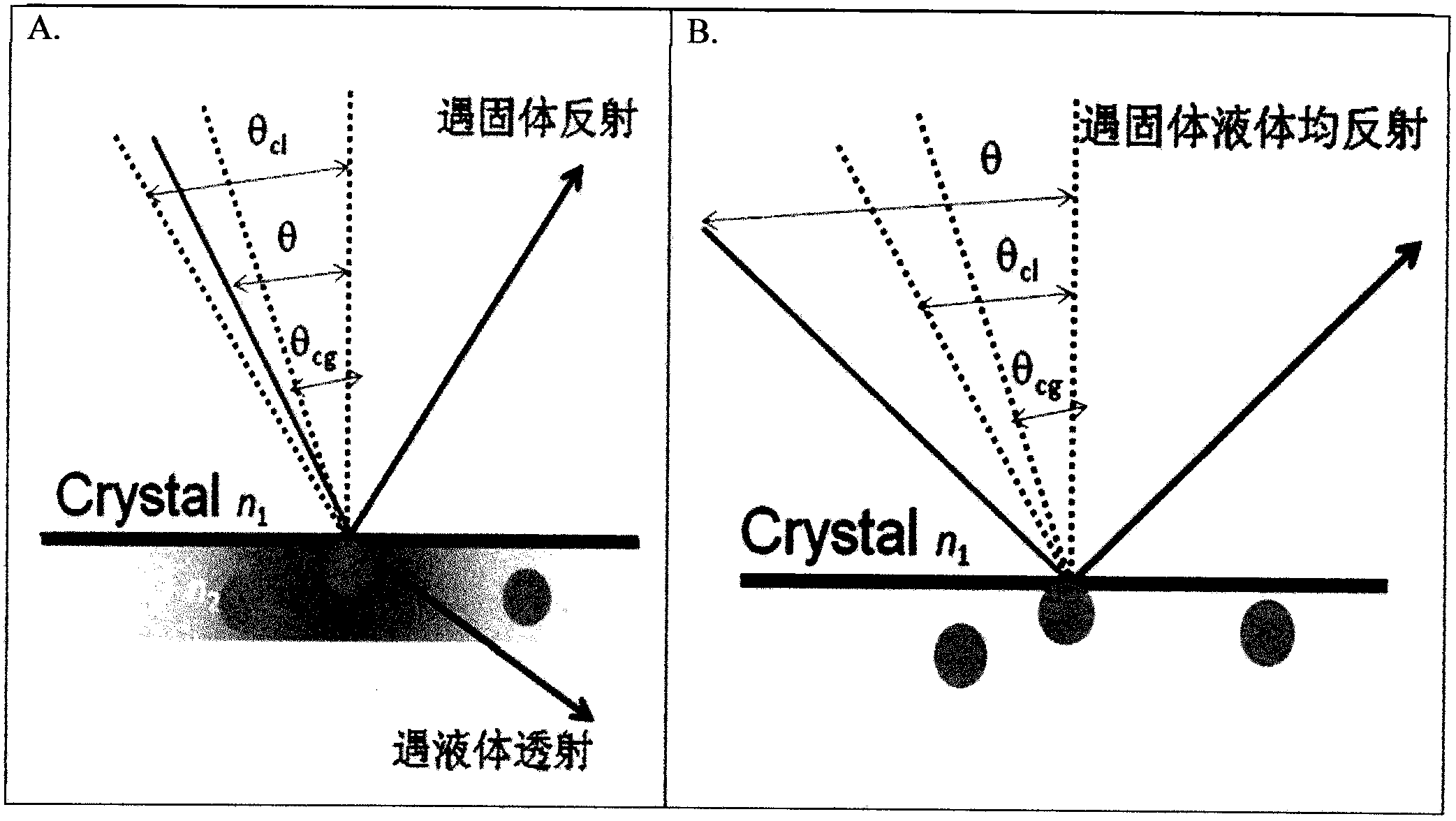

Method used

Image

Examples

Embodiment Construction

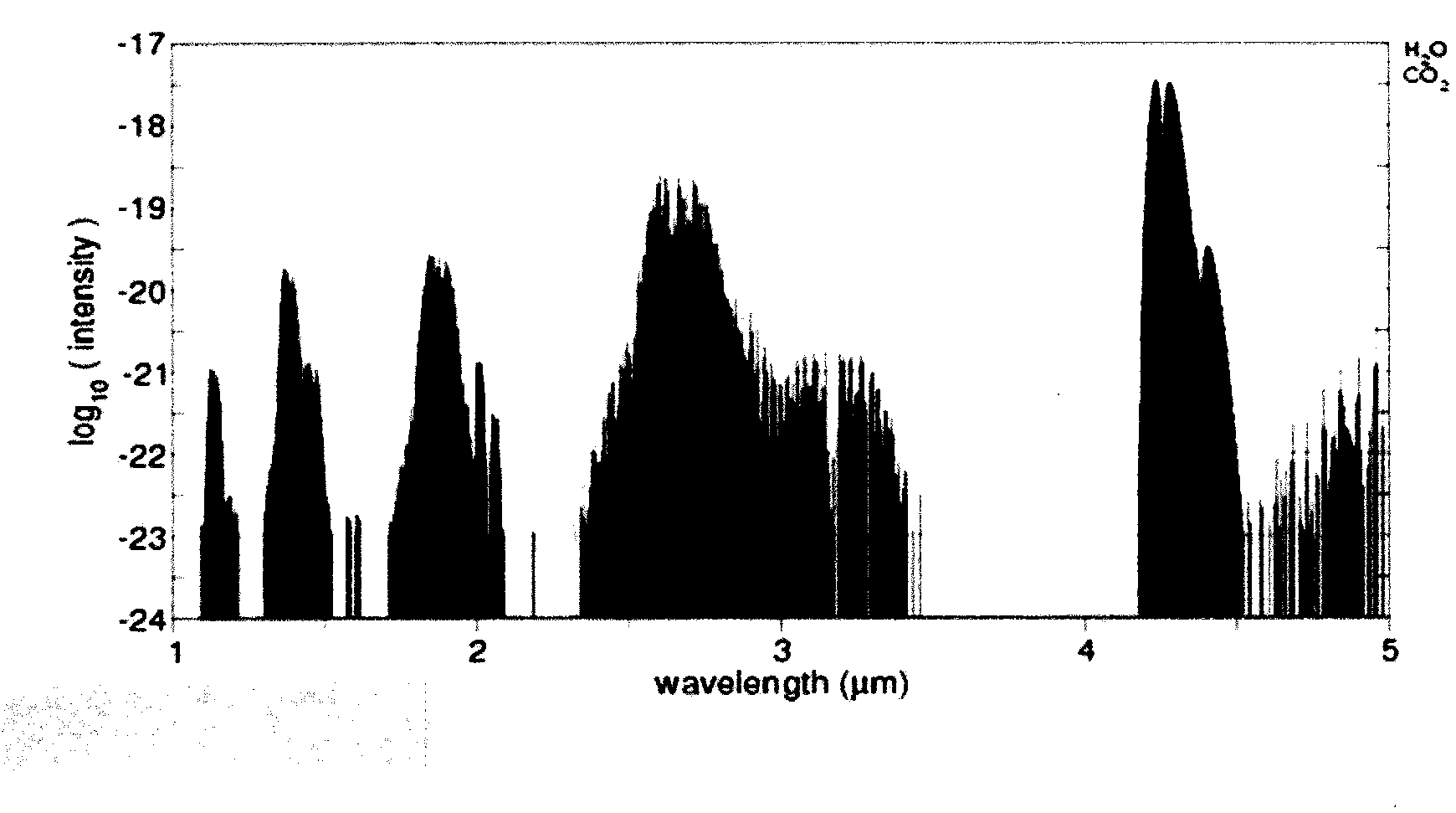

[0034] 1. Measure the content of carbon dioxide in the beer production process

[0035] Place the sensor disclosed in the present invention in direct contact with the liquid, optionally in or downstream of the reactor.

[0036] Set the working wavelength of the optical filter in front of the detector at 4.27 microns, and set the reference wavelength at 4.00 microns. Calculate the measured light intensity through equations [2] and [3] to obtain the dissolved carbon dioxide content. Figure 7 As shown, the sensor can accurately measure the carbon dioxide concentration in representative beer for a long time. The left figure shows the difference between the measured value of the sensor (red line) and the theoretical prediction value (green line) in the whole process in the temperature range of 7-2°C All links have maintained a high degree of fitting. Especially in the process of temperature changes, the sensor always maintains a quantitative display of the degree of agreement betw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com