Biosensor and manufacturing method thereof

A biosensor and insulating layer technology, applied in biological testing, instruments, scientific instruments, etc., can solve technically difficult problems, achieve smooth and uniform diffusion, simple manufacturing methods, and improve accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0094] Example 1 Using an elliptical reagent diffusion control zone to add reactive reagents to electrodes

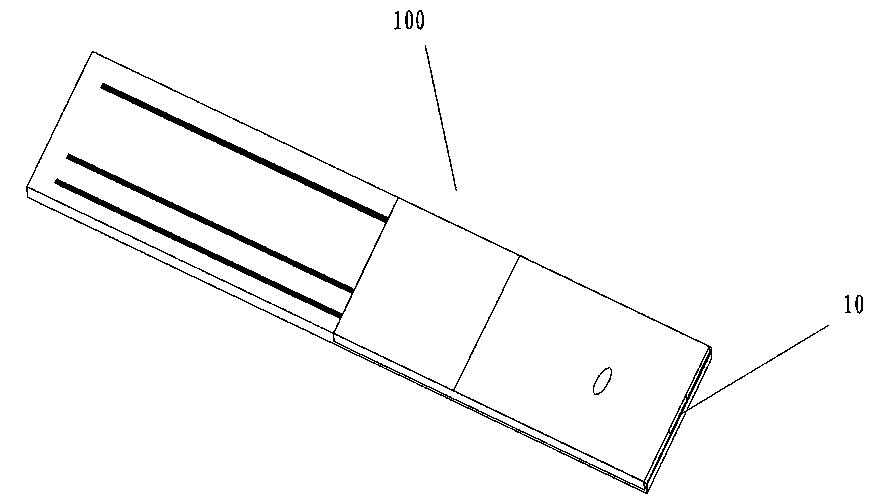

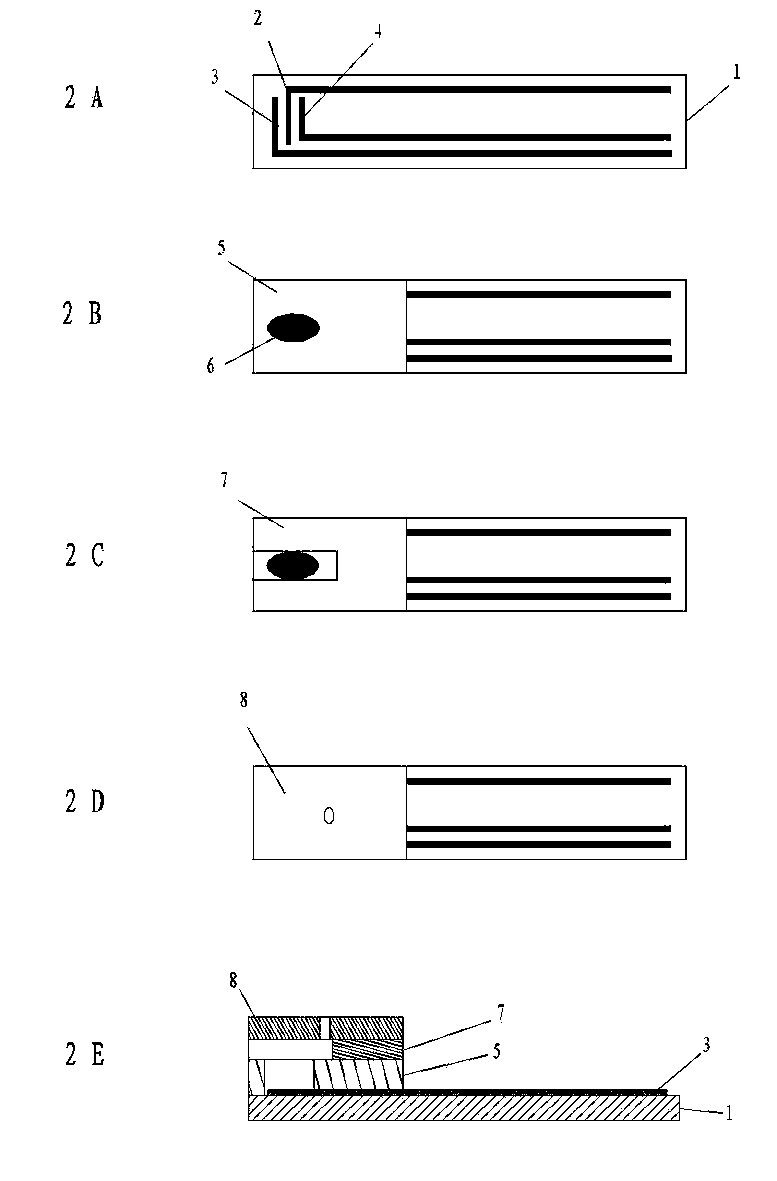

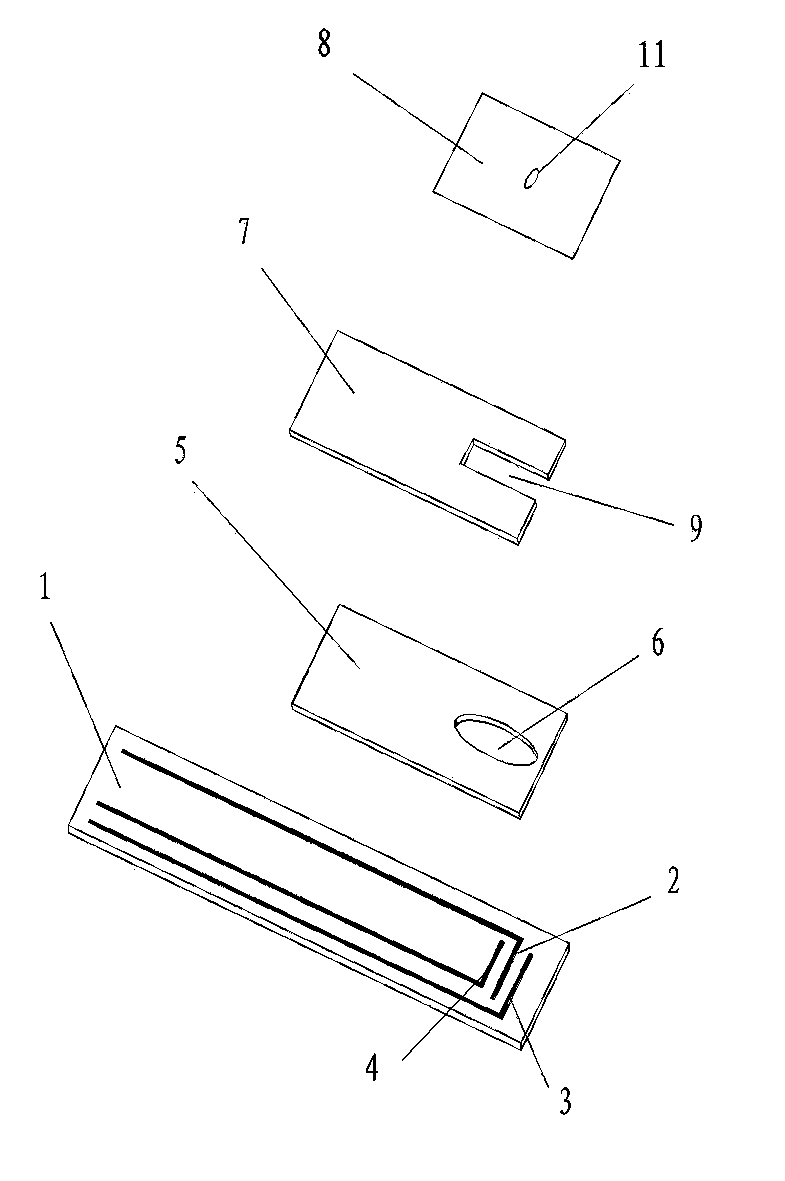

[0095] like image 3 The shown biosensor includes an insulating base plate 1 , a working electrode 2 , a counter electrode 3 and a reference electrode 4 . The electrode system is covered with a reactive reagent diffusion control layer 5, the control layer 5 includes a reactive reagent diffusion control area 6 with an oval shape, and the opening area of the reagent diffusion control area 6 is the same as the area of the reagent to be added to the electrode and Just above the electrode active area. The biosensor described in this embodiment also includes a space fabrication layer 7 and an upper cover 8 with a vent hole.

[0096] In the biosensor fabrication process, the reaction reagent is added to the electrode through the elliptical reagent diffusion control area by the method of spotting. After the reagents were added to the electrode system, the distribution of...

Embodiment 2

[0098] Example 2 Using a circular reagent diffusion control zone to add reactive reagents to electrodes

[0099] like Figure 5 Shown is the reaction reagent diffusion control layer 5 in which the shape of the reaction reagent diffusion control region 6 is circular. In the biosensor fabrication process, the reaction reagent is added to the electrode through the circular reagent diffusion control area by the method of spotting. After the reagents were added to the electrode system, the distribution of the reagents on the electrodes was photographed with a digital stereo microscope (microscope model MOTICAM 2306, manufacturer McDior Industrial Group Co., Ltd.) to observe the distribution of the reagents on the electrodes. picture. like Image 6 It is shown that the added reaction reagent diffuses uniformly on the working electrode 2, the counter electrode 3 and the reference electrode, and no reagent overflows the edge 6-1 defined by the reagent diffusion control zone. And t...

Embodiment 3

[0101] Example 3 Addition of Reagents on Electrode System with Assisted Diffusion Electrode

[0102] like Figure 7 The electrode system of the shown biosensor includes functional electrodes 2 , 3 , 4 and an auxiliary electrode 12 . The biosensor also includes a reactive reagent diffusion control layer 5 with an oval shape 6 . In the biosensor fabrication process, the reaction reagent is added to the electrode through the elliptical reagent diffusion control area by the method of spotting. After the reagents were added to the electrode system, the distribution of the reagents on the electrodes was photographed with a digital stereo microscope (microscope model MOTICAM 2306, manufacturer McDior Industrial Group Co., Ltd.) to observe the distribution of the reagents on the electrodes. picture. like Figure 8 It is shown that the added reaction reagent diffuses uniformly on the electrode, and no reagent overflows the edge 6-1 defined by the reagent diffusion control zone. An...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com