Sample containing device for cone calorimeter and method for measuring fused solid and liquid samples by using same

A technology of cone calorimeter and holding device, which is applied in measurement devices, chemical analysis by combustion, instruments, etc., can solve the problems of difficulty in guaranteeing the radiation intensity of samples, inability to guarantee test accuracy, and difficulty in guaranteeing the accuracy of results. , to achieve good thermal insulation effect, avoid errors, and promote accurate results.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

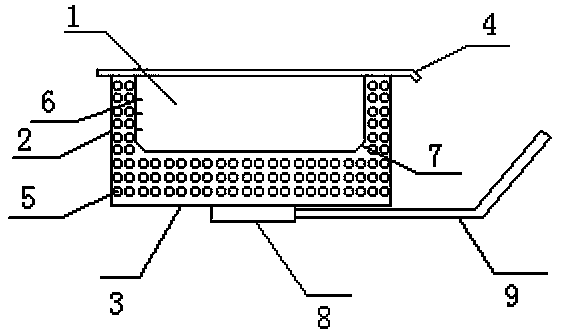

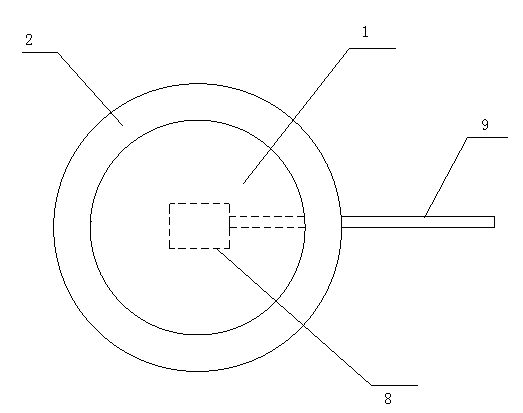

[0039] The structure of the sample holding device for the cone calorimeter described in this embodiment is as follows: figure 1 and figure 2 shown. It includes a cavity 1, and a side wall 2 and a bottom wall 3 surrounding the cavity 1. The cross section of the cavity is circular; the device is also provided with a movable baffle 4 for covering the cavity. The inside of the side wall 2 and the bottom wall 3 is provided with a cavity, and the cavity is filled with ceramic fiber cotton 5 for heat insulation. The side wall 2 surrounding the cavity 1 is provided with a scale 6, the height of the cavity is 60 mm, the zero point of the scale 6 is located at the bottom wall of the cavity, and the maximum scale is 40 mm. Rounded corners 7 are provided at the connection between the side wall 2 and the bottom wall 3 . A base 8 is disposed at the center of the outer side of the bottom wall 3 . The base 8 is connected with a handle 9, the length of the handle is 100-160mm, and the wid...

Embodiment 2

[0041] By adopting the design test method of the invention, the cone calorimeter test can be directly carried out on oily substances. Using the sample holding device for the cone calorimeter described in Example 1, proceed as follows:

[0042] S1. Preheat the cone calorimeter, and calibrate according to the standard method ISO5660-2002;

[0043] S2. Put the workshop oil sample to be tested directly into the cavity until the scale shows 10mm, and cover the movable baffle;

[0044] S3. Set the required radiation intensity, perform a baseline scan, place the sample holding device containing the sample to be tested in step S2 on the weighing device of the cone calorimeter, and open the weighing device after the reading of the weighing device is stable. Movable baffles and radiating cones are tested.

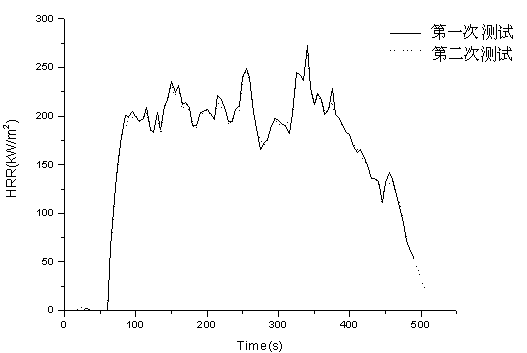

[0045] The tested HRR curve is as image 3 shown, from image 3 It can be seen that the repeatability and reliability of the two results tested using the device and method of the...

Embodiment 3

[0047] By adopting the design test method of the invention, the cone calorimeter test can be directly carried out on the solid that will melt during combustion. Using the sample holding device for the cone calorimeter described in Example 1, proceed as follows:

[0048] S1. Preheat the cone calorimeter, and calibrate according to the standard method ISO5660-2002;

[0049] S2. Make the solid sample to be tested to match the size of the cross-sectional area of the cavity, then add it into the cavity, and cover with a movable baffle;

[0050] S3. Set the required radiation intensity, perform a baseline scan, place the sample holding device containing the sample to be tested in step S2 on the weighing device of the cone calorimeter, and open the weighing device after the reading of the weighing device is stable. Movable baffles and radiating cones are tested.

[0051] At the same time, the measurement device described in ISO5660-2002 and the sample holding device of the presen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com