Fuel cell engine system and load increase and load decrease control method

An engine system, fuel cell technology, applied in the direction of fuel cells, fuel cell additives, electrochemical generators, etc., can solve the problems of shortening the service life of fuel cells, fuel cell voltage fluctuations, catalyst attenuation, etc., to reduce the voltage The effect of reducing the fluctuation of electric potential and improving the life of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention is further described below in conjunction with embodiment and accompanying drawing.

[0029] The fuel cell engine system includes air system, hydrogen system, cooling circulation system, stack module

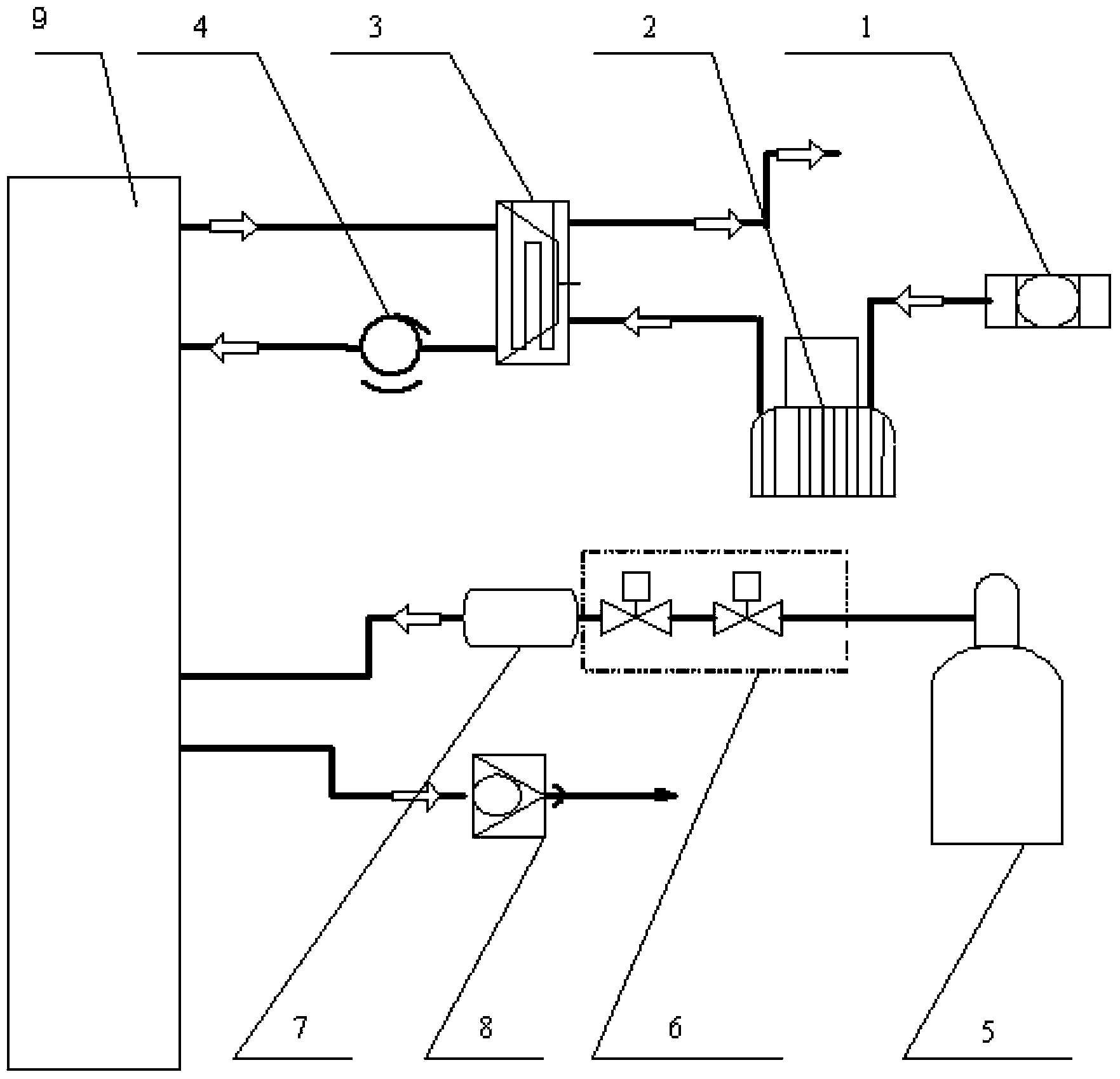

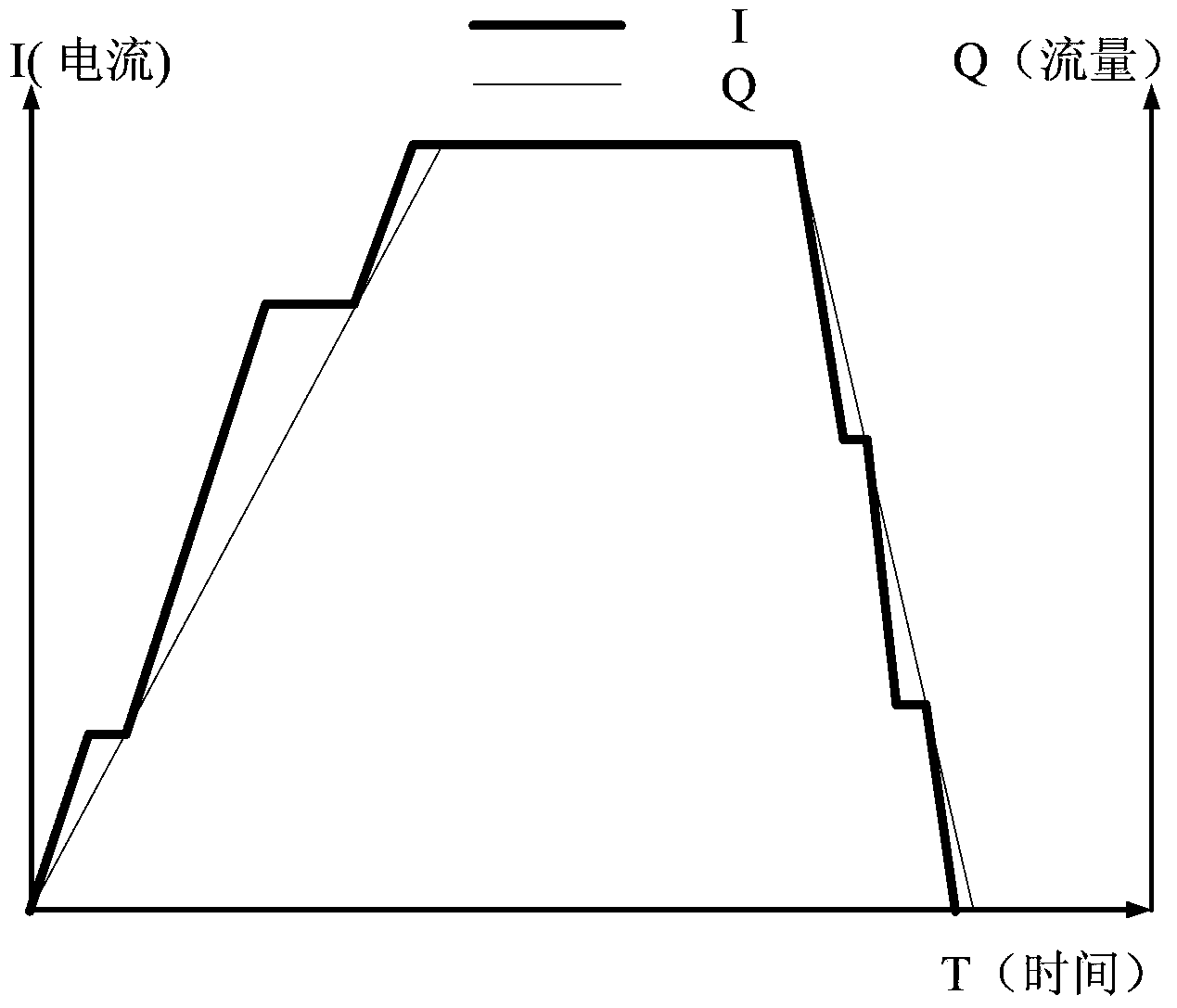

[0030] (9) and electric control system; air system includes filter muffler (1), air supply mechanism (2), humidifier (3) and water separator (4); hydrogen system includes hydrogen storage tank (5), control valve (6), hydrogen exhaust valve (8) and buffer tank (7), the buffer tank (7) is installed on the pipeline between the control valve (6) and the hydrogen inlet of the stack module (9), the stack Module (9) is a 400-cell battery module, the hydrogen utilization rate in the working condition test is higher than 95%, the cathode stoichiometric ratio is 2.5, that is, S is 2.5, and the minimum loading stoichiometric ratio is 2.0, that is, S 1 is 2.0, the highest stoichiometric ratio of load reduction is 3.0, that is, S 2 It is 3, that is, the stoichi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com