Heat tracing cable for oil tank, pipeline and oil extraction

A heating cable and heating cable technology, applied in the direction of heating element material, heating element shape, etc., can solve the problems of difficult to make long-lasting and thermally efficient electric heating elements, short service life of cables, high power consumption, etc., to achieve working performance Stable and reliable, uniform heating temperature and small thermal hysteresis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be described in detail below with the best embodiment 。

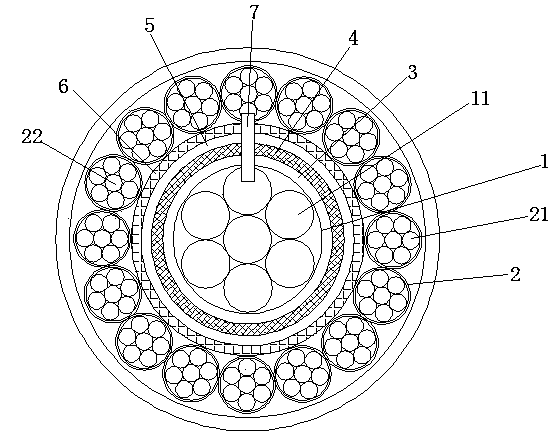

[0011] Such as figure 1 As shown, the present invention is a heat tracing cable for oil tanks, pipelines and oil production, including a power supply lead 1 and a carbon fiber heating cable 2, and a carbon fiber insulation layer 3 and a resin insulation layer are sequentially spaced between the power supply lead 1 and the carbon fiber heating cable 2. Layer 4, shielding layer 5 and glass fiber braided layer 6; the carbon fiber heating cable 2 is twisted outside the glass fiber braided layer 6; the power supply wire 1 and the carbon fiber heating cable 2 are connected through electrodes 7. The power wire 1 is formed by twisting several copper wires 11 . The copper wire 11 is a bare copper wire or a galvanized copper wire. The carbon fiber heating cable 2 is formed by twisting several carbon fiber filaments 21 and aramid filaments 22 . The heating cable used for oil tanks, pipel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com