Reconstructed tobacco leaves containing basic incense substances in tobaccos prepared by water extraction method and ethanol extraction method and cigarettes produced by reconstructed tobacco leaves

A technology of reconstituted tobacco leaves and aroma substances, applied in the field of tobacco, can solve the problems of not meeting the taste requirements of reconstituted shredded tobacco, difficulty in large-scale industrial production, single spices, etc., so as to enhance the sense of body fluid in smoke and set off the natural aroma of smoke , enhance the effect of fragrance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 0

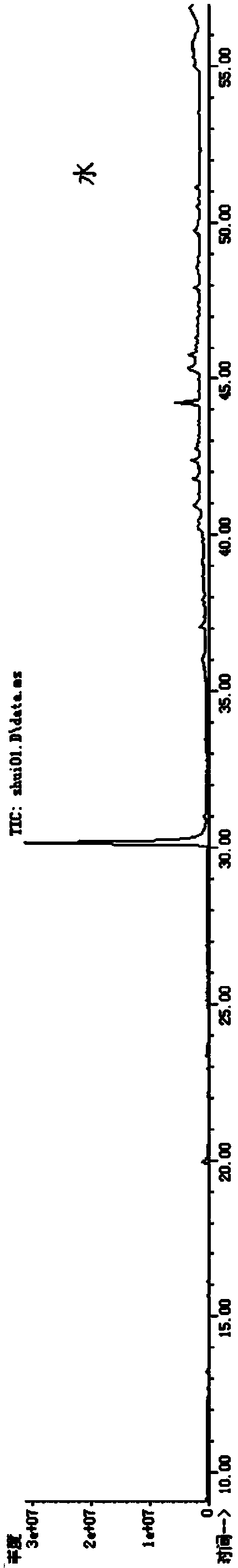

[0030] Take 40kg of waste soot and extract it with 280L of water at 40°C for 1 hour, filter, concentrate the extract to a density of 1.2g / mL, take 10,000g of water-extracted concentrate, and add it to 10kg of reconstituted tobacco leaf substrate as a control sample group.

Embodiment 1

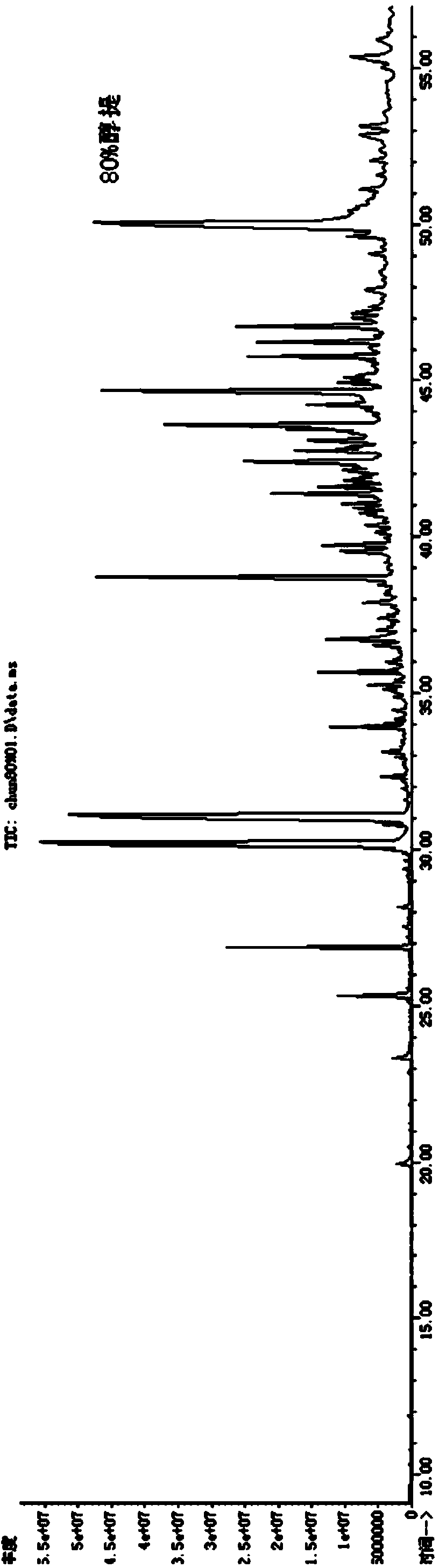

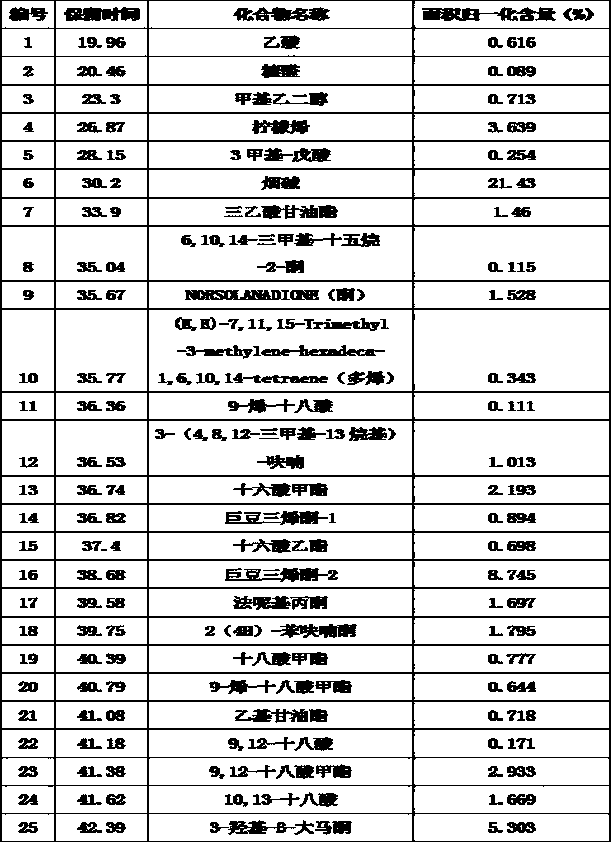

[0032] Take 40kg of waste soot and extract it with 200L of water at 50°C for 1 hour, filter, concentrate the extract to a density of 1.2g / mL, and extract the concentrated solution with water for later use; take 10kg of waste soot and use 40L of 80% ethanol at 50°C for 2 hours, extracted twice, and concentrated the extract to a density of 1.2 g / mL; took 10,000 g of water extract concentrate and 300 g of ethanol extract concentrate, mixed them evenly, added them to 10 kg of reconstituted tobacco leaves, and smoked them through sensory evaluation. Compared with the control sample group, the aroma transparency and brightness are slightly better, with a slightly sweet aroma, the smoke has a certain softness, the concentration is medium +, there are floating thorns in the mouth, and the aftertaste is slightly astringent.

Embodiment 2

[0034] Take 40kg of waste soot, stir and extract with 200L water at 40°C for 1 hour, extract twice, filter, concentrate the extract to a density of 1.2g / mL, and extract the concentrated solution with water for later use; take 10kg of waste soot and use 80L of 60% ethanol at 70°C, The extraction time was 1 hour, and the extraction was performed once, and the extract was concentrated to a density of 1.2 g / mL; 10,000 g of water extraction concentrate and 200 g of ethanol extraction concentrate were mixed evenly and added to 10 kg of reconstituted tobacco leaves. Smoking evaluation, compared with the control sample group, the aroma transparency is slightly better, the smoke concentration is medium +, it is still delicate and agglomerated, there are floating thorns in the mouth, slightly woody, and the aftertaste is slightly astringent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com