Adhesive conveying system with dosage control

A dose control and glue delivery technology, which is applied to the surface coating liquid device, coating, etc., can solve the problems of fluid pressure changes on the pipe wall, easy blockage, and affecting the delivery volume of A glue, etc., to achieve stable delivery and simple structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

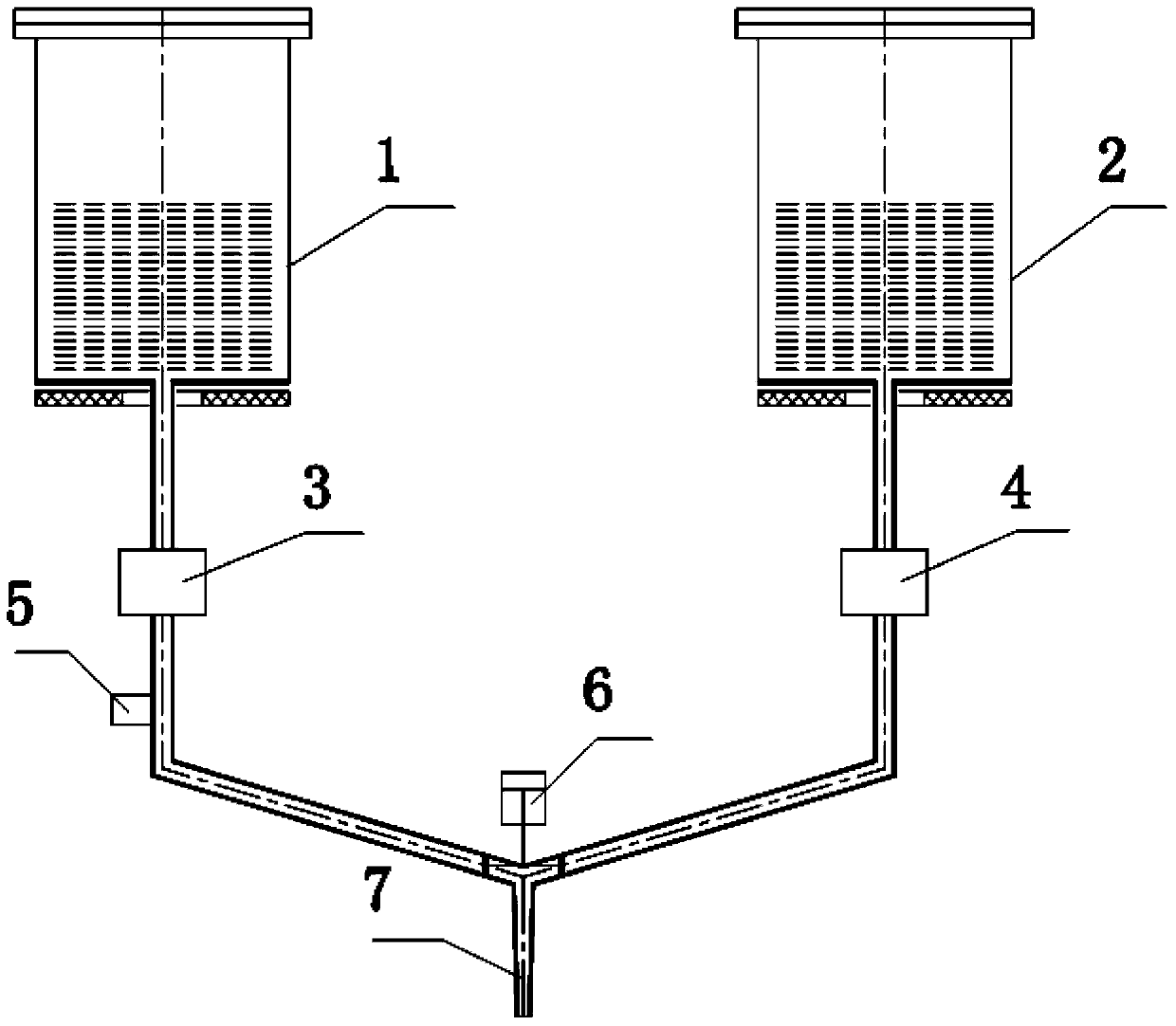

[0016] combine figure 1 , figure 2 Specifically describe the embodiment of the invention, a rubber hose pressure detection device, A glue barrel 1 is equipped with A glue, B glue barrel 2 is equipped with B glue, A glue barrel 1 is connected with the metering pump 3 outside the barrel through a pipeline, The metering pump 3 is connected with the rubber mixing valve 6 through the pipeline; the B rubber barrel 2 is connected with the metering pump 4 outside the barrel through the pipeline, and the metering pump 4 is connected with the rubber mixing valve 6 through the pipeline, and the rubber mixing valve 6 is connected with the sprayer Glue gun 7 connection. Glue A and glue B are respectively pumped by the metering pump 3 and metering pump 4 to the rubber mixing valve 6 to converge, and then flow out from the glue gun 7, thus forming the delivery path of the A / B glue.

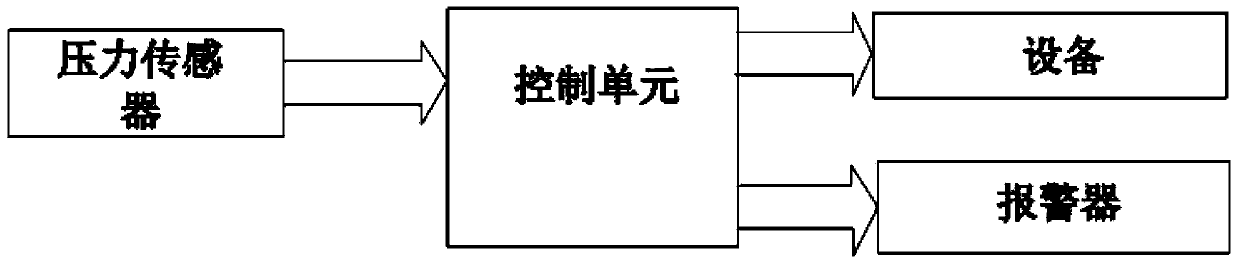

[0017] In the glue delivery path of A, a pressure sensor 5 is provided on the pipeline connecting the mete...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com