No-discharge sewage treatment system

A sewage treatment system and discharge technology, which is applied in the fields of water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc. consumption, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

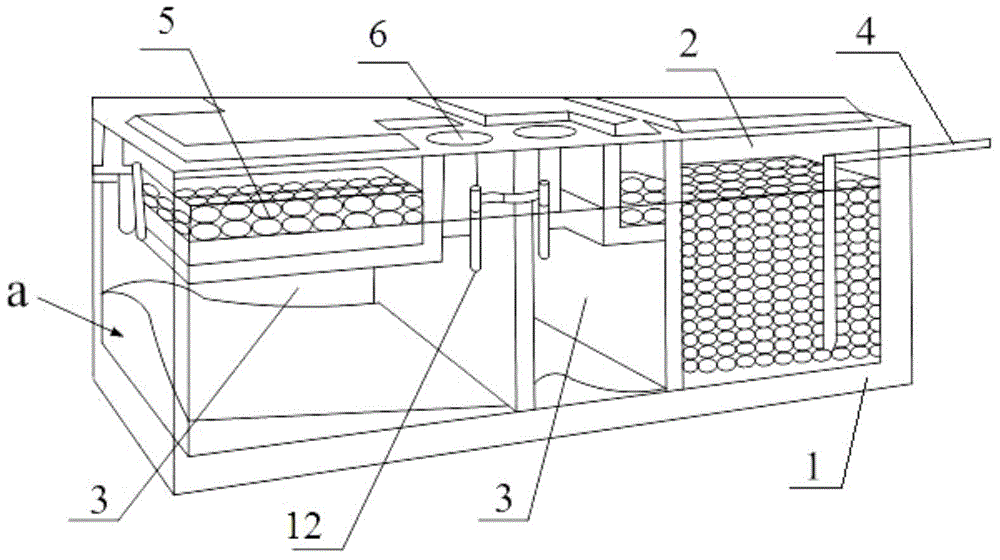

[0021] Such as Figure 1 to Figure 3 The non-discharge sewage treatment system shown includes three parts: a pretreatment device 1, a precision water filtration device and a soil purification device;

[0022] The pretreatment device 1 includes a corruption chamber 3 and a preliminary filter chamber 2, the preliminary filter chamber 2 is provided with a discharge port and a discharge port, and the corruption chamber 3 communicates with the discharge port of the preliminary filter chamber 2; The pre-filter chamber 2 is filled with filter material;

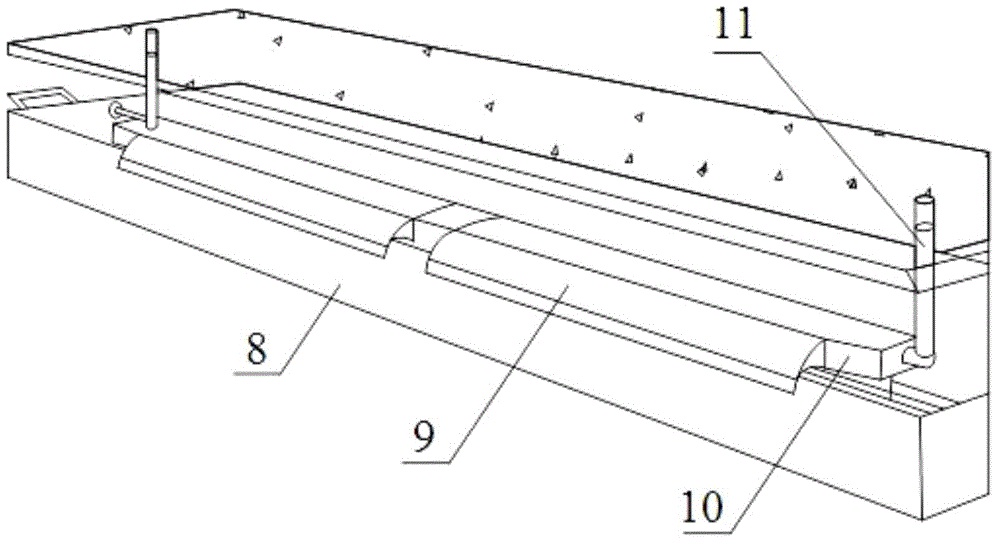

[0023] The precision water filtering device comprises: a water shielding box 8 and a water collecting pipe 10; the water shielding box 8 has a water inlet and a water outlet; the water inlet communicates with the outlet of the preparatory filter chamber 2; the water collecting pipe 10 It has a water outlet section, the water outlet section is designed as a groove structure, and the water collection pipe 10 is connected to the water ...

Embodiment 2

[0045] Based on the foregoing embodiments, the present invention has also made the following improvements:

[0046] The corruption chamber includes a primary corruption chamber and a secondary corruption chamber, and the primary corruption chamber and the secondary corruption chamber are communicated through a corruption chamber connecting pipe 12;

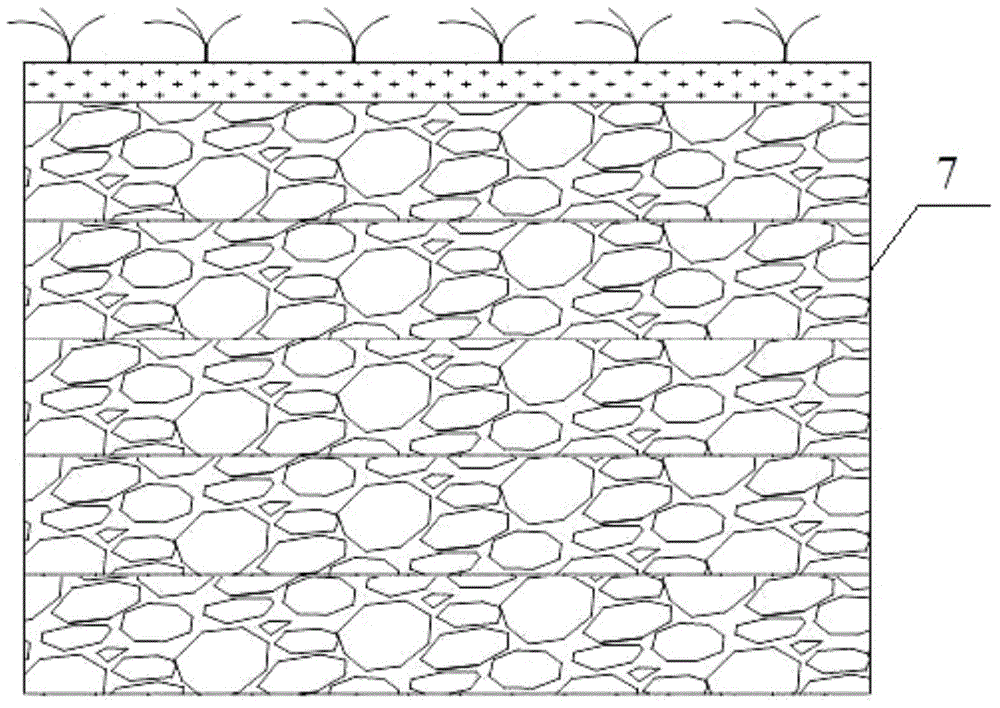

[0047] The upper side of the primary corruption chamber and the secondary corruption chamber are provided with an adsorption device 5, and the upper side of the primary corruption chamber is also provided with a filter layer;

[0048] Both the primary corruption chamber and the secondary corruption chamber are provided with a methane bacteria sludge layer a.

[0049] The primary corruption chamber and the secondary corruption chamber are provided with a sludge layer in which methane bacteria are cultivated. Under the above-mentioned anaerobic environment, the methane bacteria can carry out alkaline fermentation of the above-mentio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com