Phosphor-nitrogen halogen-free flame-retardant epoxy resin

A technology based on epoxy resin and phosphorus nitrogen system, which is applied in the field of halogen-free flame retardant epoxy resin, and can solve problems that have not been reported

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

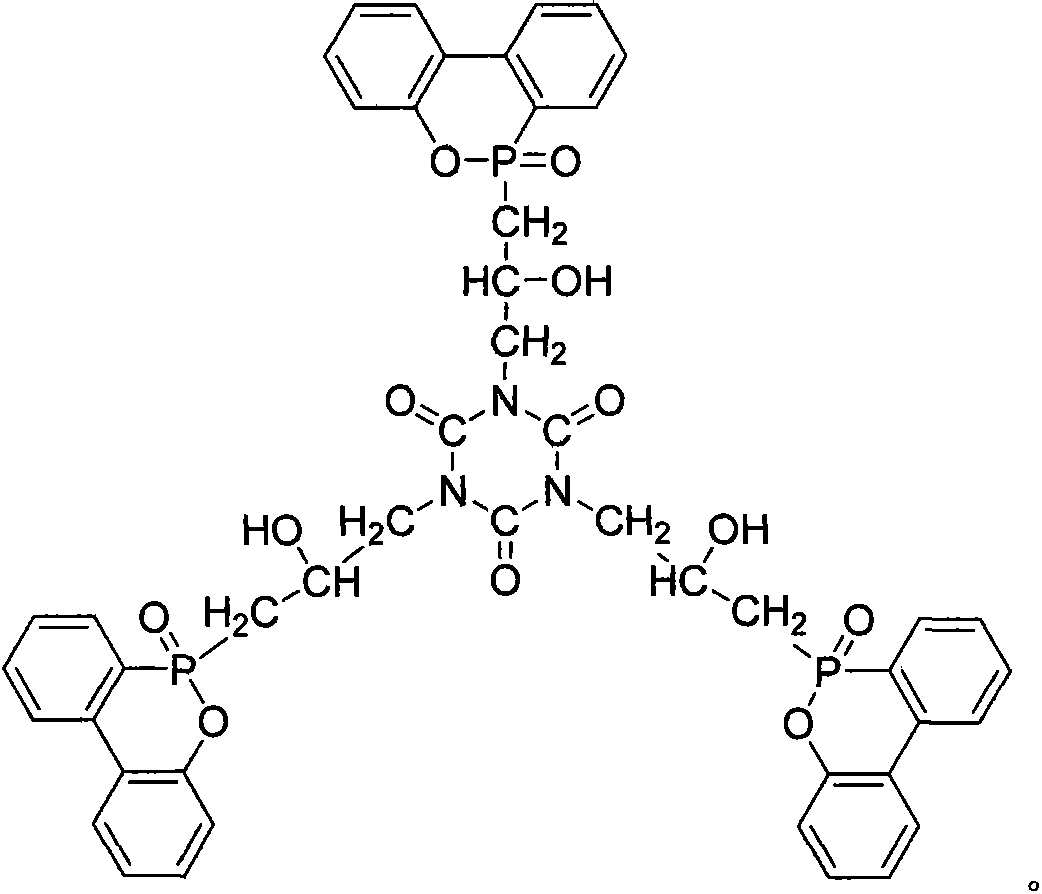

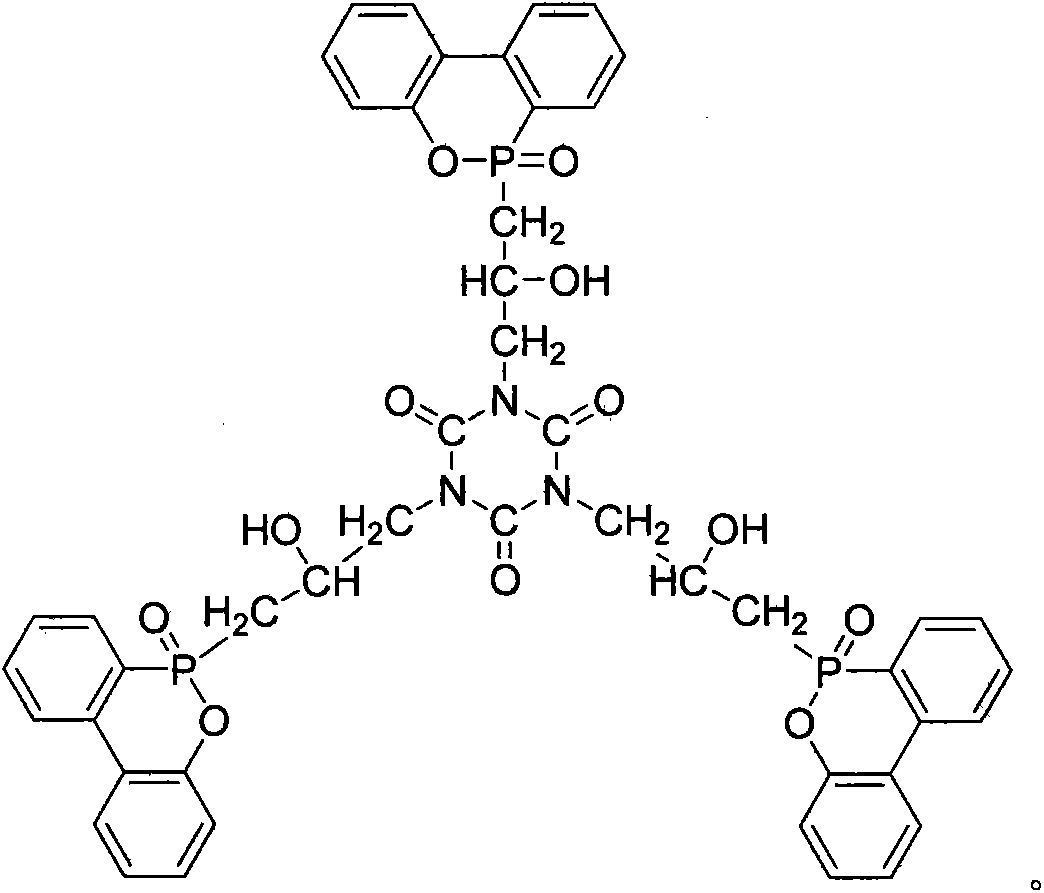

Method used

Image

Examples

Embodiment 1

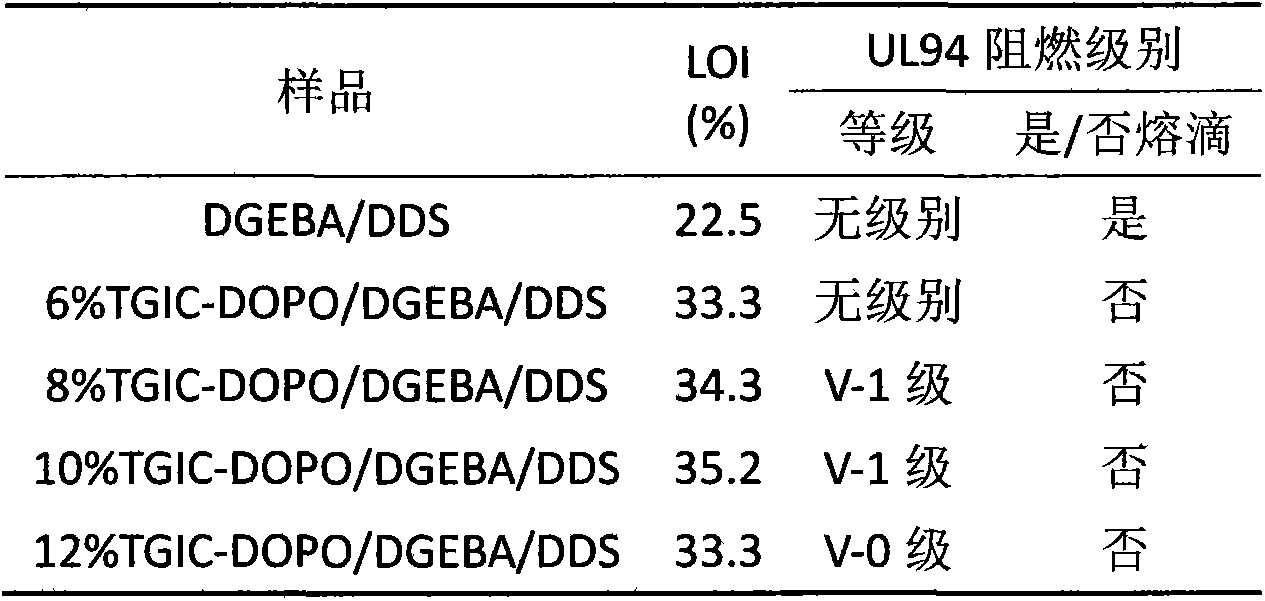

[0016] Example 1 100g of bisphenol A diglycidyl ether epoxy resin with an epoxy value of 0.51 was heated to 180°C, and 8.6g of three-(3-DOPO-2-hydroxyl-1-propyl)- Add triazinetrione into the epoxy resin, stir for 1 hour, add 31.7g DDS into the epoxy resin, stir evenly, remove the gas in the system under vacuum conditions, and then pour it into the preheated mold , pre-cured at 150°C for 3 hours, and then cured at 180°C for 5 hours, the mass fraction of TGIC-DOPO in the obtained epoxy resin cured product was 6%, and the limiting oxygen index was 33.3%.

Embodiment 2

[0017] Example 2 Heat 100g of bisphenol A diglycidyl ether epoxy resin with an epoxy value of 0.51 to 180°C, and mix 18.3g of three-(3-DOPO-2-hydroxyl-1-propyl)- Add triazinetrione into epoxy resin, stir for 1 hour, cool down the system to 75°C, add 60mL methyl ethyl ketone into epoxy resin and stir for 1 hour, add 31.7g DDS into epoxy resin, stir evenly Finally, the organic solvent in the system was removed under vacuum conditions, and then poured into a preheated mold, pre-cured at 150°C for 3 hours, and then cured at 180°C for 5 hours, the obtained epoxy resin cured product The mass fraction of TGIC-DOPO is 12%, and the flame retardant grade is UL94V-0.

Embodiment 3

[0018] Example 3 Heat 100g of bisphenol A diglycidyl ether epoxy resin with an epoxy value of 0.46 to 150°C, and mix 14.3g of three-(3-DOPO-2-hydroxyl-1-propyl)- Triazinetrione was added to the epoxy resin and stirred for 1.5 hours.

PUM

| Property | Measurement | Unit |

|---|---|---|

| limiting oxygen index | aaaaa | aaaaa |

| limiting oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com