Anti-counterfeiting ink composition containing micro-structure material, and preparation method thereof

A technology of anti-counterfeiting ink and microstructure, which is applied in the direction of ink, household utensils, applications, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

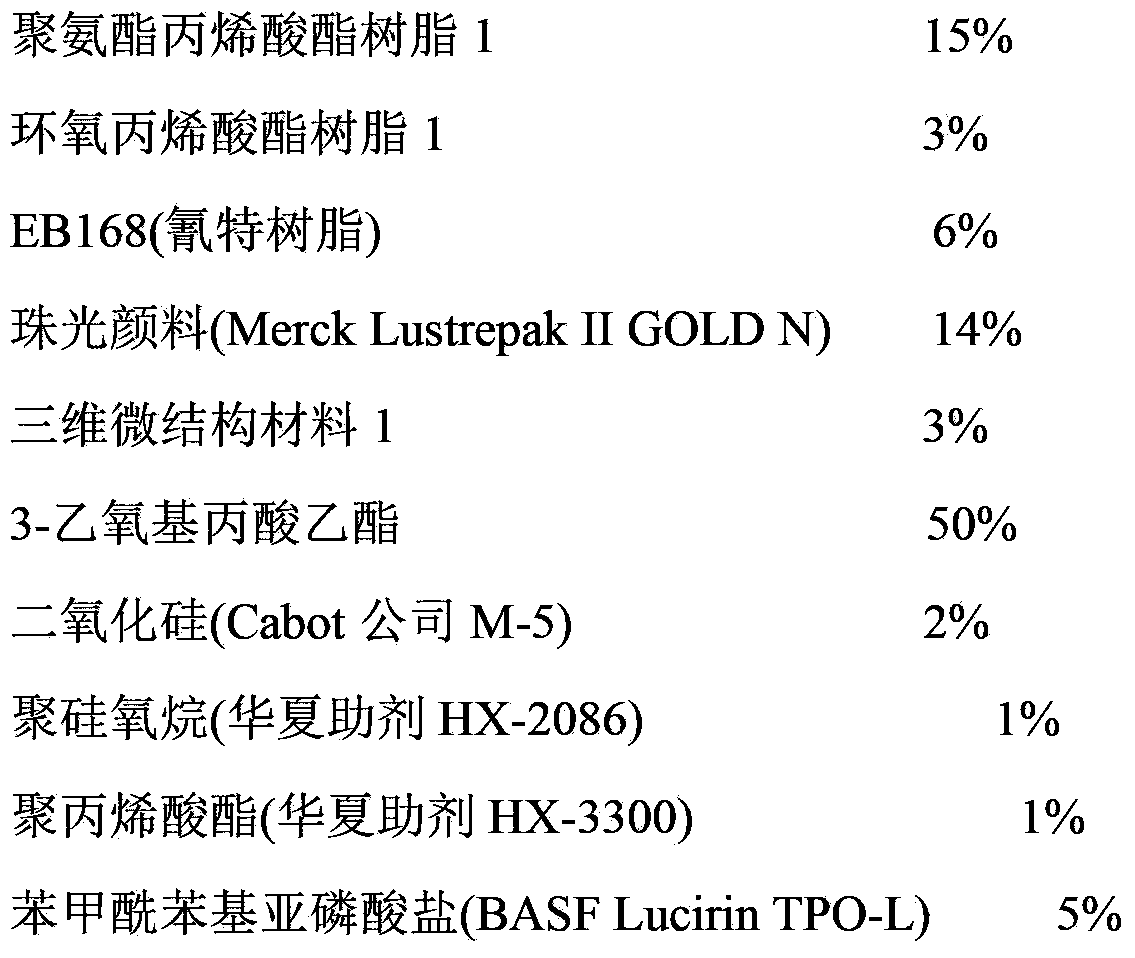

[0080] Photocurable screen printing metal microstructure material anti-counterfeiting ink composition:

[0081] Weight percent:

[0082]

[0083]The metal microstructure material used: the shape is an equilateral triangle, the side length is about 40 microns, three-layer structure, the middle is a metal layer, the metal layer is made of aluminum with a low boiling point, and the three-dimensional microstructure material is a fluorescent material layer on both sides.

[0084] The preparation method is to put all the raw materials required for the metal microstructure material anti-counterfeiting ink composition at a temperature of 45-50°C into a stirring device, start stirring, and first stir at 200 rpm for 40 minutes to make the solid The material is fully wetted by the liquid material, and then stirred at a speed of 1000 rpm for 45 minutes to disperse, so that the flake pigment and the three-dimensional microstructure metal pigment are wrapped by the ink binder, and the pr...

Embodiment 2

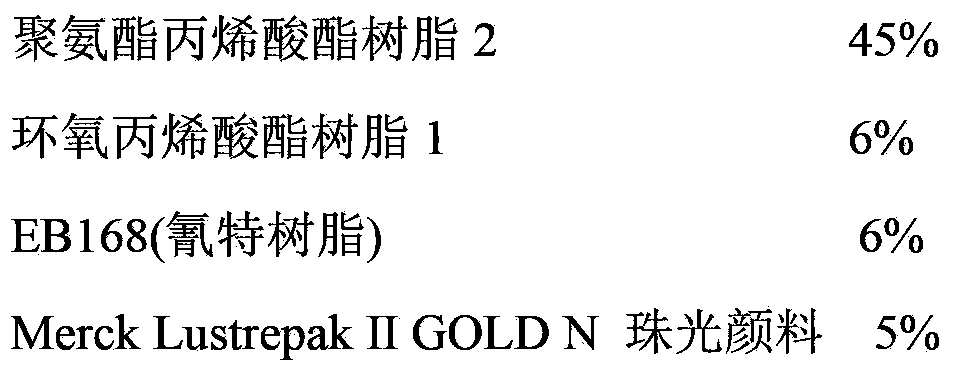

[0088] Anti-counterfeiting ink composition of photocurable screen printing metal microstructure material

[0089] Weight percent:

[0090]

[0091]

[0092] The metal microstructure material used: the shape is a regular equilateral triangle, with a side length of about 40 microns, a three-layer structure, a magnetic layer in the middle, and metal material layers on both sides. The metal layer is aluminum, and the three-dimensional microstructure formed by evaporation deposition Structural materials.

[0093] The preparation method of the metal-containing microstructure material anti-counterfeiting ink composition is the same as that in Example 1.

[0094] The metal microstructure material anti-counterfeit ink composition for silk screen printing is directly printed on a substrate according to a normal printing process. The resulting prints can be observed with a high-magnification magnifying glass to find microstructured materials with specific structures in the printe...

Embodiment 3

[0096] ——Anti-counterfeiting ink composition of metal microstructure material for oxidative polymerization drying engraving and gravure printing

[0097] The anti-counterfeiting ink composition containing the three-dimensional microstructure material of the metal substrate has the following composition:

[0098]

[0099]

[0100] The metal microstructure material used: a three-dimensional microstructure material with the shape of the letter O, a major axis outer diameter of about 20 microns, and an inner diameter of about 10 microns, with a three-layer structure, a metal layer in the middle, and Raman target layers on both sides.

[0101] The preparation method is as follows: at 45-50°C, process all other raw materials except the three-dimensional microstructure material 3 and the cobalt, manganese, and zirconium composite drier to The fineness is less than 10μm. Then referring to the preparation method of Example 1, the three-dimensional microstructure material is comp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com