Design method of hole-drilling and hole-forming process scheme for drainage of outburst coal seam

A technology for extracting drilling holes and outburst coal seams, which is applied in drilling equipment and methods, drilling equipment, mining equipment and other directions to achieve the effect of automatic design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be described in detail below in conjunction with the accompanying drawings.

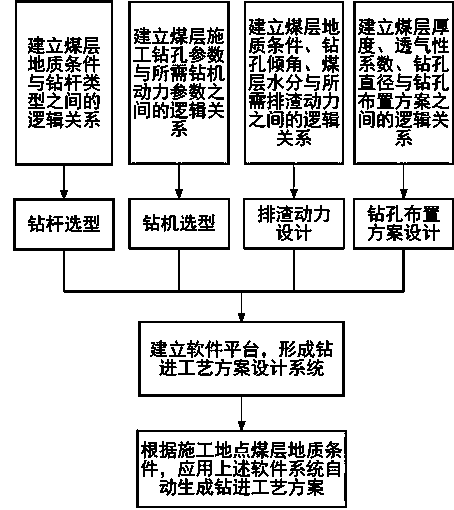

[0014] The specific implementation technical scheme of the technical scheme design method of drilling holes for outburst coal seam extraction of the present invention includes the following steps.

[0015] (1) Drill pipe selection. As for the problem of drilling outburst coal seams in my country, through a large number of previous studies, it was found that different types of drill pipes affect the drilling depth and drilling efficiency of coal seams, and there are certain rules to be found. That is, there is an optimal matching relationship between the geological conditions of the coal seam and the type of drill pipe. Therefore, the optimal drill pipe can be selected according to the change of the geological conditions of the coal seam. The geological conditions of the coal seam include the coal seam firmness coefficient f, the absolute gas emission of the coal seam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com