Circulating water-cooled plant factory LED (light-emitting diode) surface light source heat dissipation management system and method

A technology of LED surface light source and circulating water cooling, which is applied in the field of self-adaptive systems, can solve problems such as not being utilized, and achieve the effects of reducing energy consumption, ensuring luminous efficiency, and reducing light decay rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

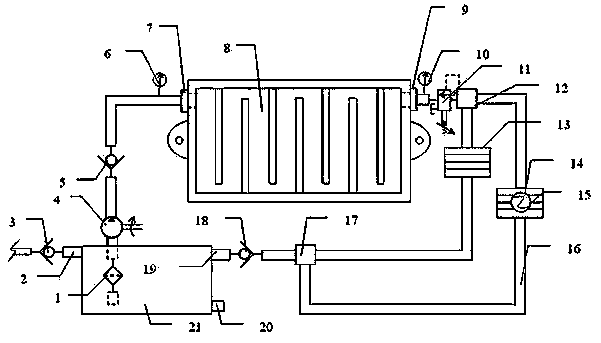

[0026] Such as figure 1 As shown, a heat dissipation management system for a circulating water-cooled plant factory LED surface light source mainly includes:

[0027] (1) LED panel heat dissipation device, this device mainly replaces the heat energy generated when LED electrons and holes recombine with hot-dip galvanized heat sink to achieve the purpose of heat dissipation.

[0028](2) Temperature measuring instrument. This measuring instrument can be used to measure the temperature of the water inlet and outlet of the LED panel cooling device. It is mainly used to calculate the heat taken away by the water passing through the LED panel cooling device. The measured heat is used to control the outdoor temperature. The speed of the fan achieves the purpose of matching the fan speed to the heat dissipation, and avoids unnecessary energy consumption caused...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com