Automatic paster robot for weld radiographic inspection

An automatic patch and radiographic flaw detection technology, applied in the direction of using radiation for material analysis, can solve problems affecting work efficiency and cost, and achieve the effect of speeding up efficiency, reducing labor intensity and reducing personal injury

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

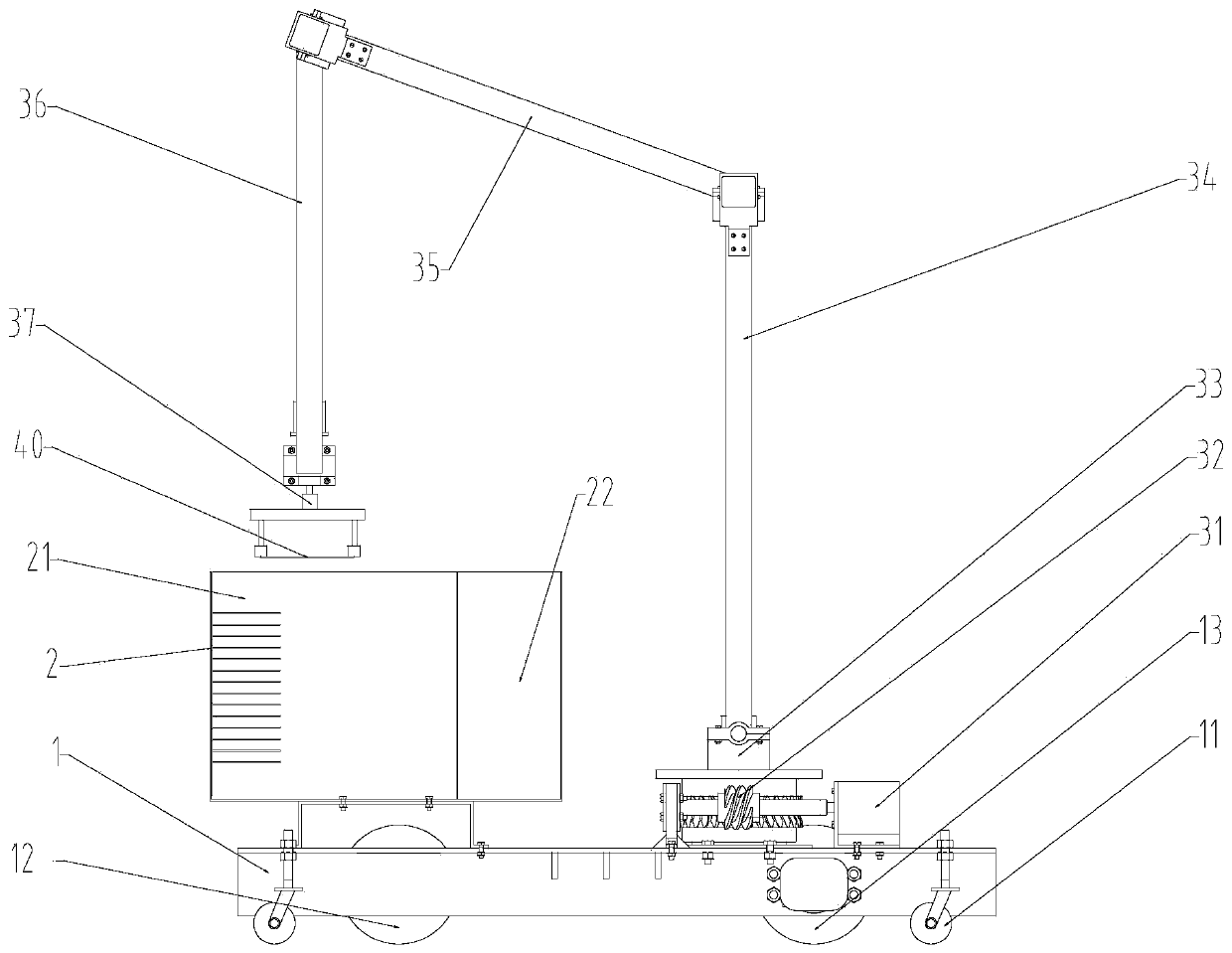

[0018] See attached figure 1 , which describes a preferred embodiment of the welding seam radiography automatic patch robot according to the present invention. The robot includes a frame, a frame traveling mechanism carrying the frame to move, a real-time detection system located on the upper part of the frame, and a lead box for storing films.

[0019] The rack walking mechanism includes a six-wheel walking trolley, which includes four wheels at both ends of the trolley and two universal wheels at the bottom of the trolley; the four wheels are symmetrically arranged at both ends of the trolley, and any wheel at the front and rear ends is the active wheel. Each driving wheel has a driving wheel shaft and a wheel drive motor respectively. The wheel driving motor is connected to the driving wheel shaft through a coupling. There are two rolling bearings between the driving wheel shaft and the driving wheel. The driving motor drives the driving wheel shaft to rotate, thereby drivi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com