Capacitive microcomputer electromagnetic field sensor

A magnetic field sensor and electromagnetic field technology applied in the field of sensors to achieve the effects of easy driving, reliable performance and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

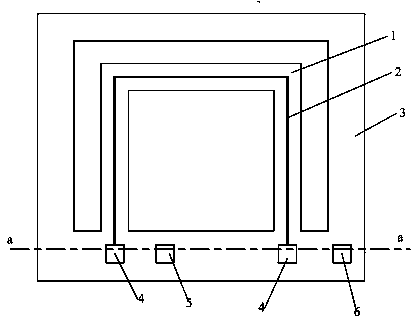

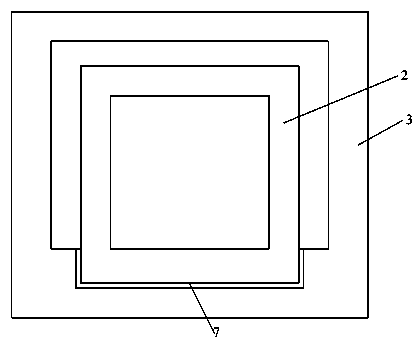

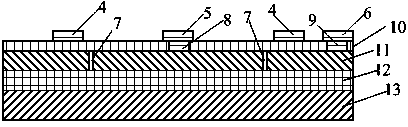

[0015] The technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0016] like Figure 1 to Figure 3 As shown, a capacitive microcomputer electromagnetic field sensor of the present invention includes a silicon substrate 13 , a silicon dioxide layer 12 , a polysilicon layer 11 and a silicon nitride layer 10 stacked in sequence from bottom to top. The middle part of the silicon dioxide layer 12 is hollow. A U-shaped beam 1 is arranged in the middle of the polysilicon layer 11 and the silicon nitride layer 10 . The U-shaped beam includes a polysilicon layer on the lower part and a silicon nitride layer on the upper part. The polysilicon layer of the U-shaped beam and the polysilicon layer 11 are located in the same layer, and the silicon nitride layer of the U-shaped beam and the silicon nitride layer 10 are located in the same layer. The surroundings of the silicon nitride layer 10 are set as anchor regio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com