An online determination method of sintered fuel ratio

A judging method and fuel technology, applied in the direction of electrical program control, comprehensive factory control, etc., can solve the problems of inability to judge the ratio of sintered fuel in real time and inaccurate judgment, and solve the problem of not being able to judge the ratio of sintered fuel in real time, the principle Concise and adaptable to the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

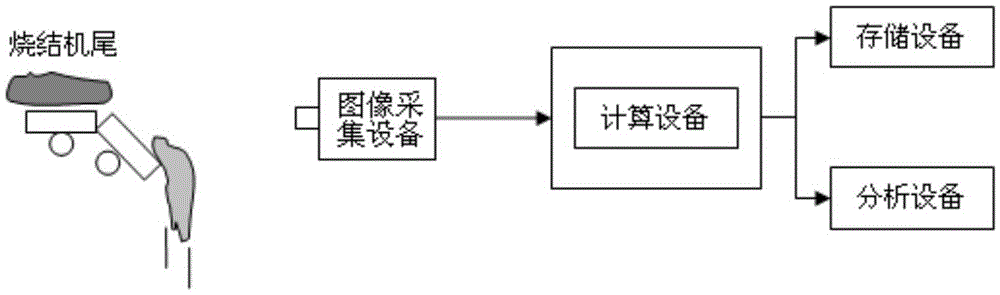

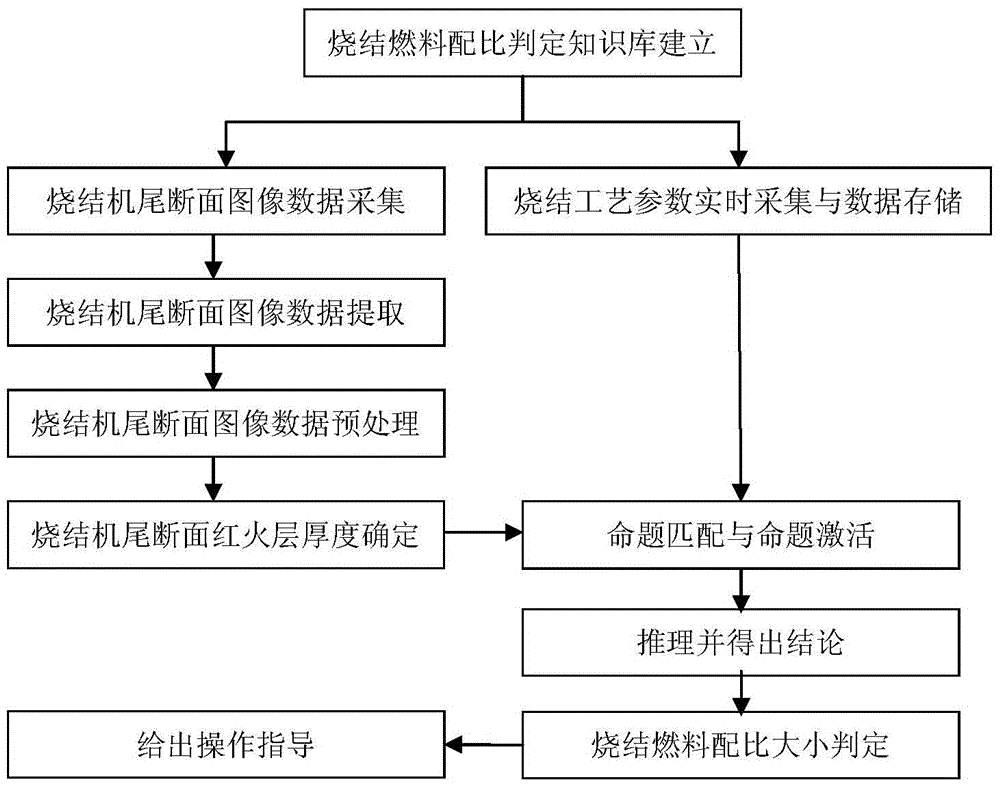

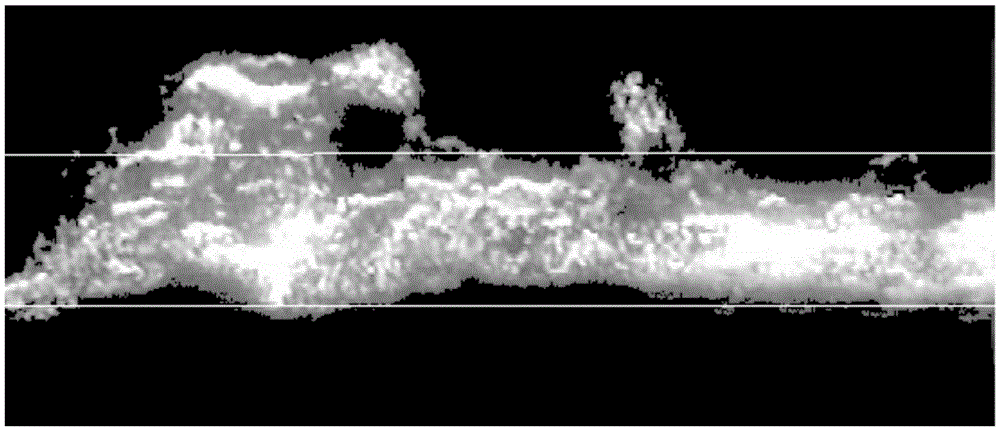

[0036] The equipment of the present invention constitutes as figure 1 As shown, it includes image acquisition equipment, computing equipment, storage equipment and analysis equipment. An image acquisition device is installed at the tail of the sintering machine, and the image acquisition device may be a video camera or a camera with a camera function and other imaging equipment. The image acquisition device is connected with the computing device, and the computing device is responsible for extracting, preprocessing and analyzing the collected images. The computing device can be a computer, single-chip microcomputer, DSP, FPGA and other computing and processing devices with programming capabilities. The storage device is responsible for storing the field parameters collected in real time and the real-time data, historical data and knowledge base of the calculated red fire layer thickness value. The analysis device adopts the expert system method to determine the size of the sin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com