Iron core reactance regulator with current control and short-circuit current-limiting functions and control method thereof

A short-circuit current limiting and power flow control technology, which is applied in the direction of output power conversion devices, AC power input conversion to AC power output, conversion equipment that can be converted to DC without intermediate conversion, etc., can solve the problem of low economy and device volume. and huge investment in equipment to achieve the effect of high reliability, simple structure and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

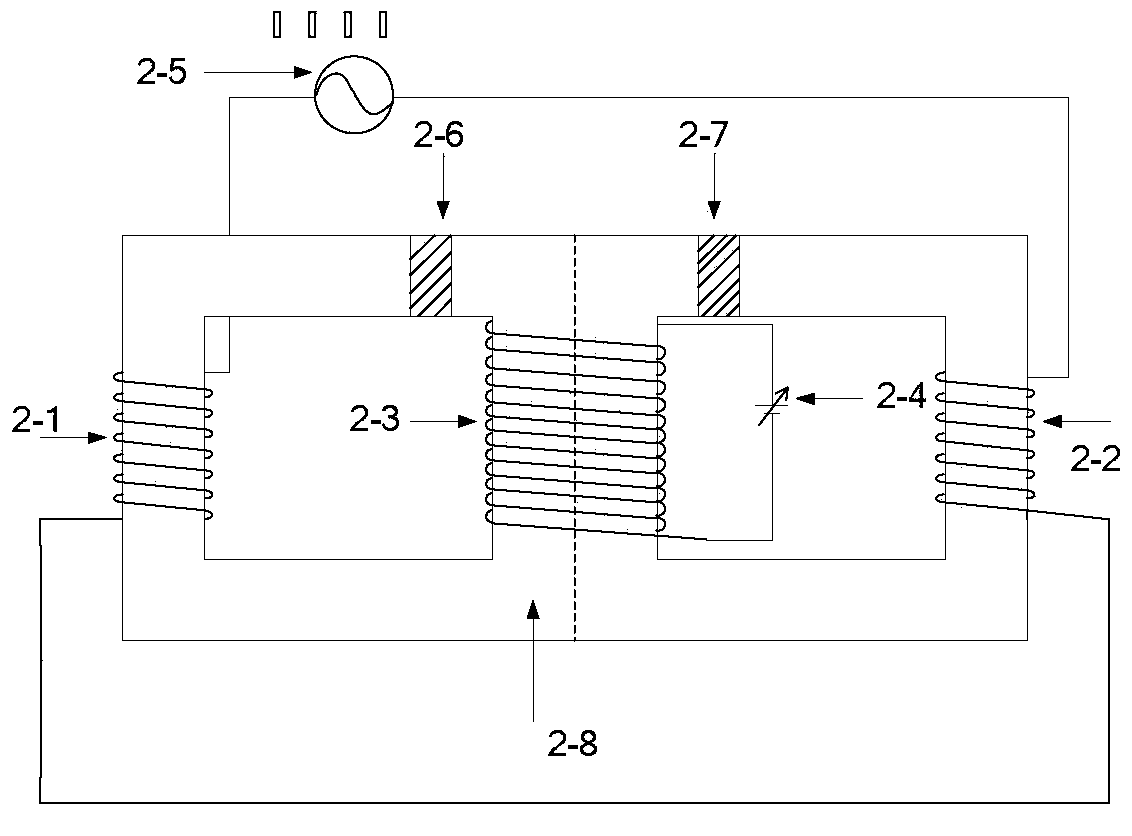

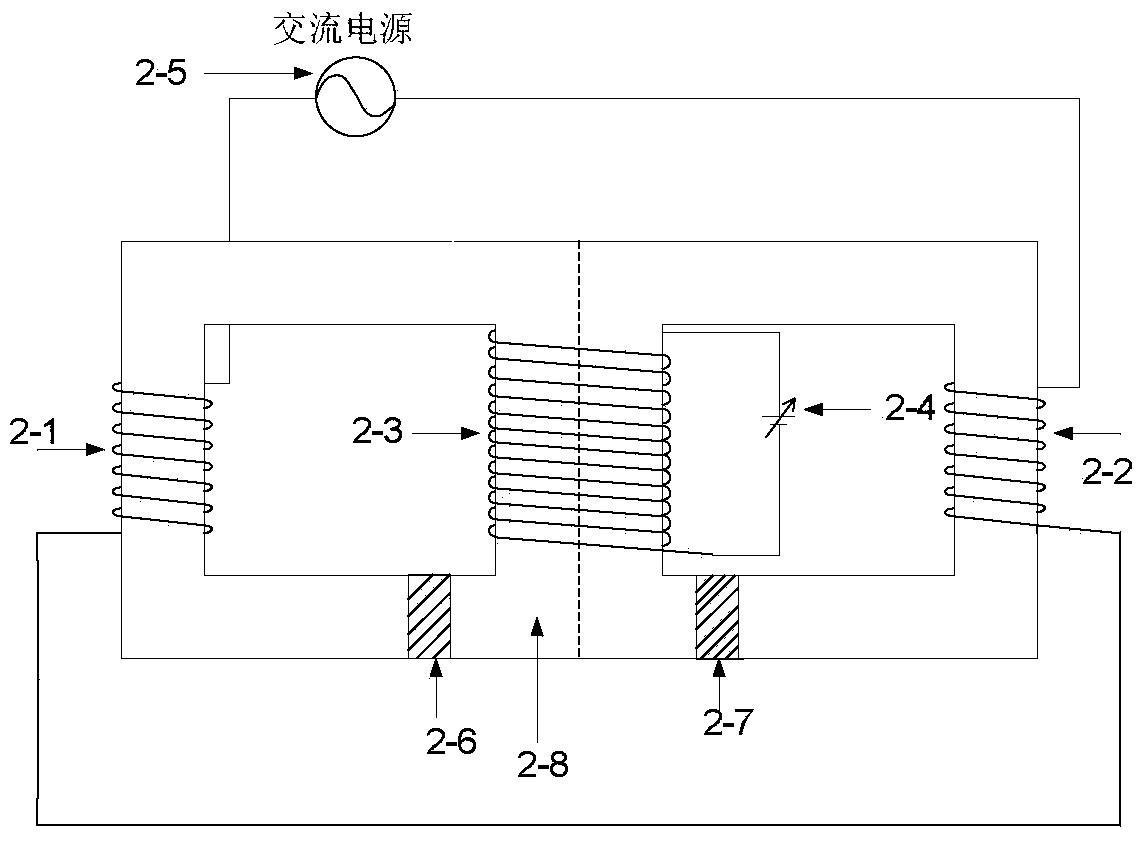

[0027] The iron core reactance regulator of the present invention includes two types: for the single-phase structure, two square-shaped iron cores are set, and each square-shaped iron core has a middle iron core column, a side column, an upper magnetic yoke and a lower magnetic Yoke, the upper yoke opens an air gap of a specific size. In the single-phase structure, the middle columns of the two square-shaped iron cores are combined to form a combined middle column. The DC coil is wound on the combined middle column and connected to the adjustable bias DC source. The adjustable bias DC source can be adjusted according to the needs. Changing the saturation of the iron core changes the output fundamental reactance of the iron core reactance adjusting device. AC coils are wound on the side columns of the two square-shaped iron cores, and the two AC coils are connected at the same end and then connected in series to the power grid.

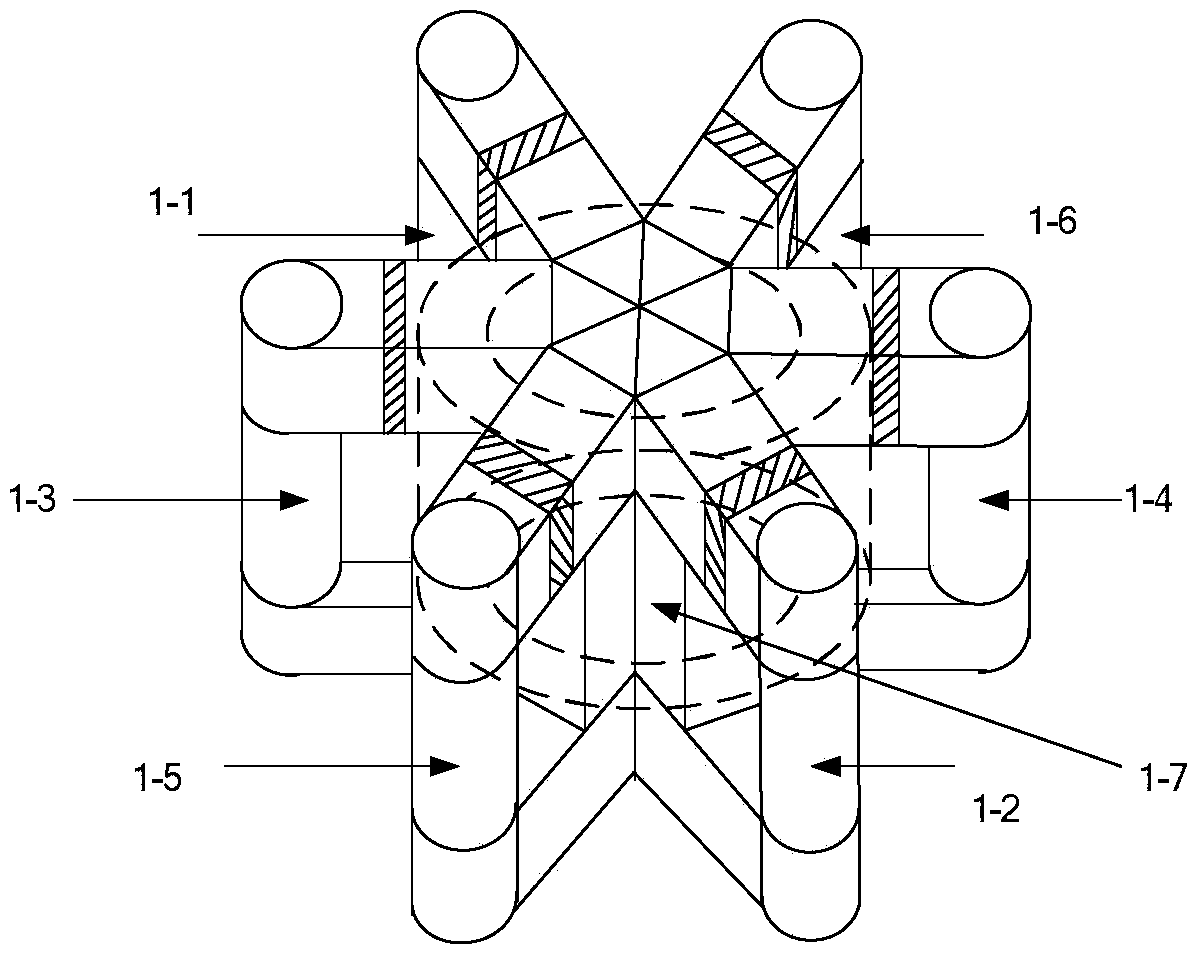

[0028] For the three-phase structure, set 6 squ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com