Thermochemical system with housing made of composite material

A thermochemical and enclosure technology, applied in the field of thermochemical systems with enclosures made of composite materials, can solve the problems of non-competitiveness, increased system cost burden, damage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

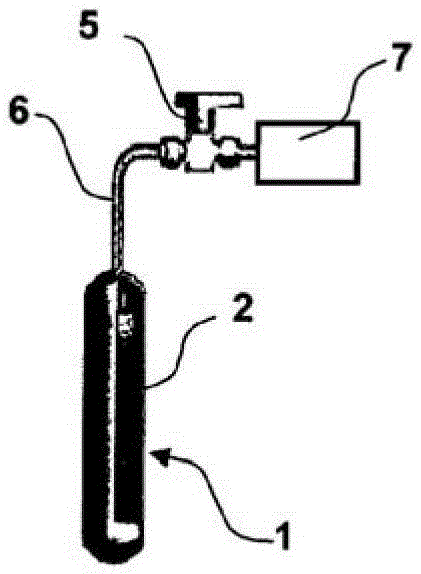

[0024] exist figure 1 The thermochemical system shown schematically above basically comprises a reactor 1 containing reactants 2 and communicating with external use parts 7 via pipes 6 under the control of a control valve 5 . As explained below and known, the reactant and the specific gas are such that the reactant can absorb the gas by an exothermic thermochemical reaction, and then when the reactant 2 is heated, release the gas by a reverse thermochemical reaction.

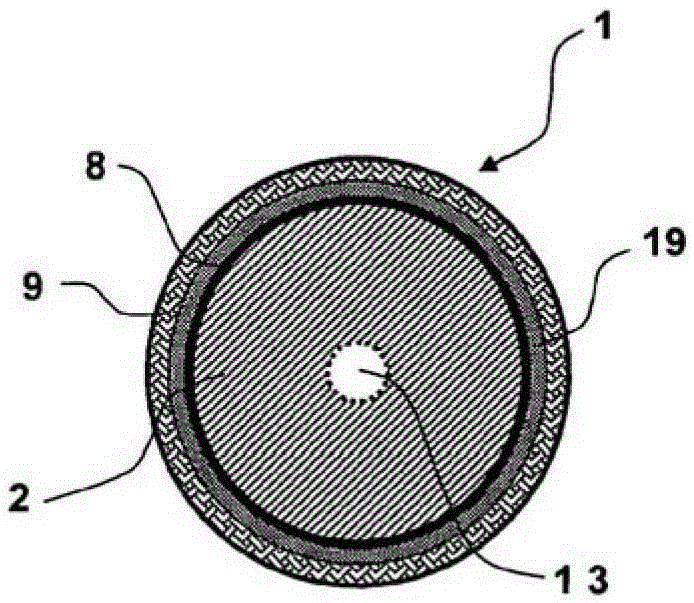

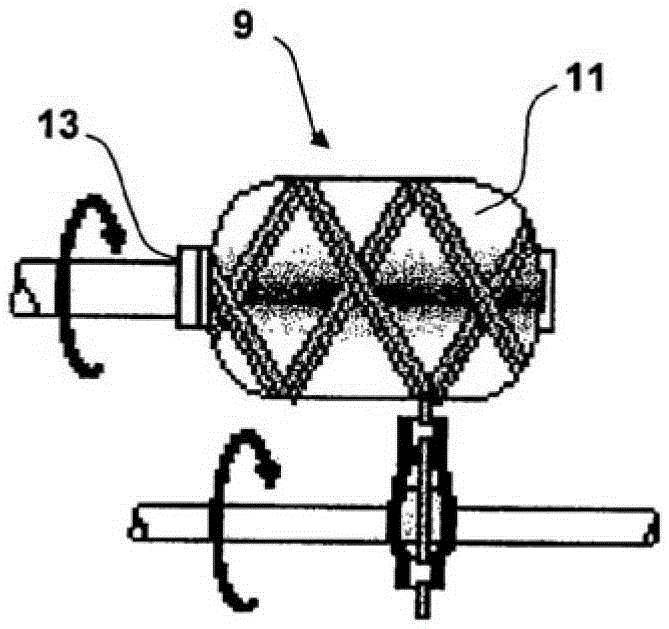

[0025] exist figure 2 In the embodiment of the invention shown above, the main body of the reactor 1 consists of two enclosures, an inner enclosure 8 or "liner" and an outer enclosure 9 .

[0026] The inner casing 8 itself is formed from two metal elements, in particular made of stainless steel, a cylindrical body 8a of lesser thickness of about 1 mm, the shape of the bottom of which is preferably hemispherical and in Its upper part is open to receive a hemispherical head 8b fixed to the body, for example by ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com