Covering method and structure for degradable film of flue-cured tobacco ridge culture

A technology of covering structure and degrading film, which is applied in the fields of botanical equipment and methods, horticulture, plant protection cover, etc., can solve the problems of high temperature of soil temperature, failure of covering to increase production, and easy blowing of mulch film. The effect of improving the utilization rate of fertilizer and moisturizing the root system of tobacco plants

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

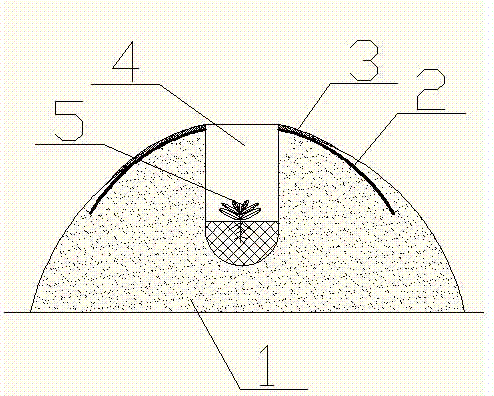

[0017] Example 1, such as figure 1 Shown, the specific implementation steps of the present invention are:

[0018] (1) Site selection: Select a smoke field with a soil depth of more than 30cm and gentle terrain.

[0019] (2) Soil preparation: deep plowing before ridge formation, the depth of the plow layer should be more than 15cm, after plowing, rake evenly, and remove the sundries in the smoke field.

[0020] (3) Base fertilizer application: Before ridge formation, apply flue-cured tobacco base fertilizer in strips according to the amount of fertilizer required by conventional tobacco leaves.

[0021] (4) Ridging: Single ridge 1 is used, and the ridge 1 is erected after the rainy day before planting. Ridge height: 22cm-25cm for soil smoke, 25cm-28cm for field smoke, and 40cm wide at the top of the ridge body. It is required to dig deep and loosen the bottom of the ridge when raising the ridge, so that the ridge body is loose, the ridge is straight, the soil is fine, full,...

Embodiment 2

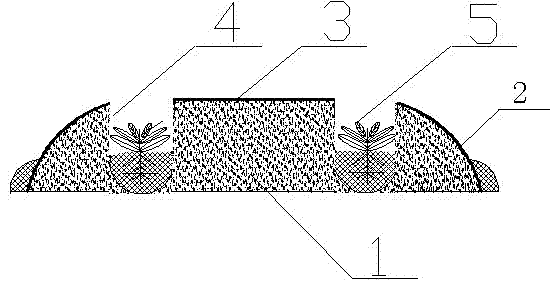

[0026] Example 2, such as figure 2 Shown, the specific implementation steps of the present invention are:

[0027] (1) Site selection: Select a smoke field with a soil depth of more than 30cm and gentle terrain.

[0028] (2) Soil preparation: deep plowing before ridge formation, the depth of the plow layer should be more than 15cm, after plowing, rake evenly, and remove the sundries in the smoke field.

[0029] (3) Base fertilizer application: according to the distance between the rows of tobacco plants between ridges of 90-100cm, and the distance between rows of tobacco plants of 110-120cm between two ridges, open a 15cm deep small ditch along the direction, and apply base fertilizer according to the amount of base fertilizer applied to conventional flue-cured tobacco strips before ridge formation .

[0030] (4) Ridging: Double row flat ridges 1 are used, and the ridges are opened according to the 210cm bottom of the ridge to form a ridge 1 with a width of 150-160cm. The h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com