Grinding head installation base of groove grinding machine

A technology for mounting seats and grinding grooves, which is applied to the parts of grinding machine tools, grinding machines, grinding/polishing equipment, etc., and can solve problems such as unusable, low precision, and design errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The present invention will be further described below in conjunction with accompanying drawing:

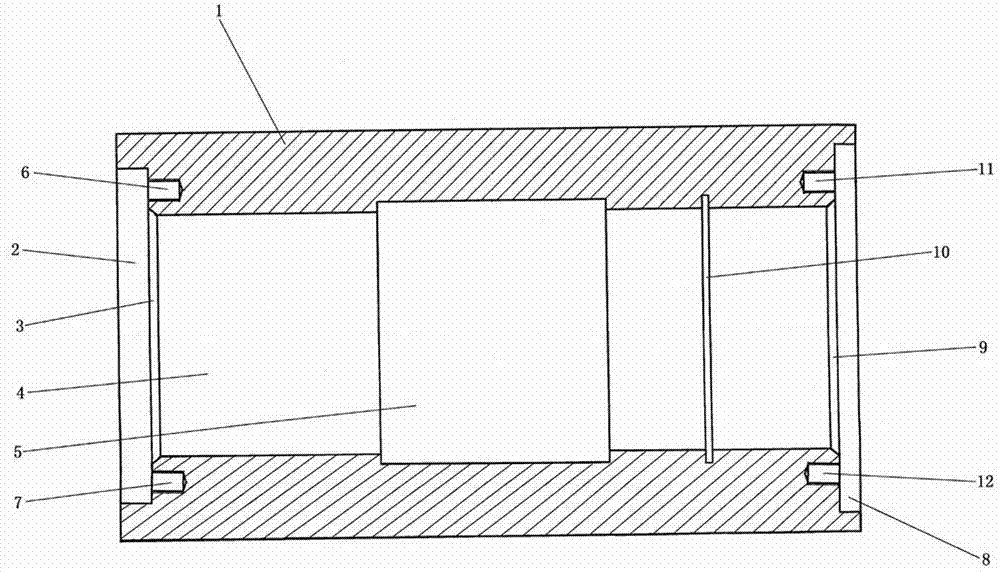

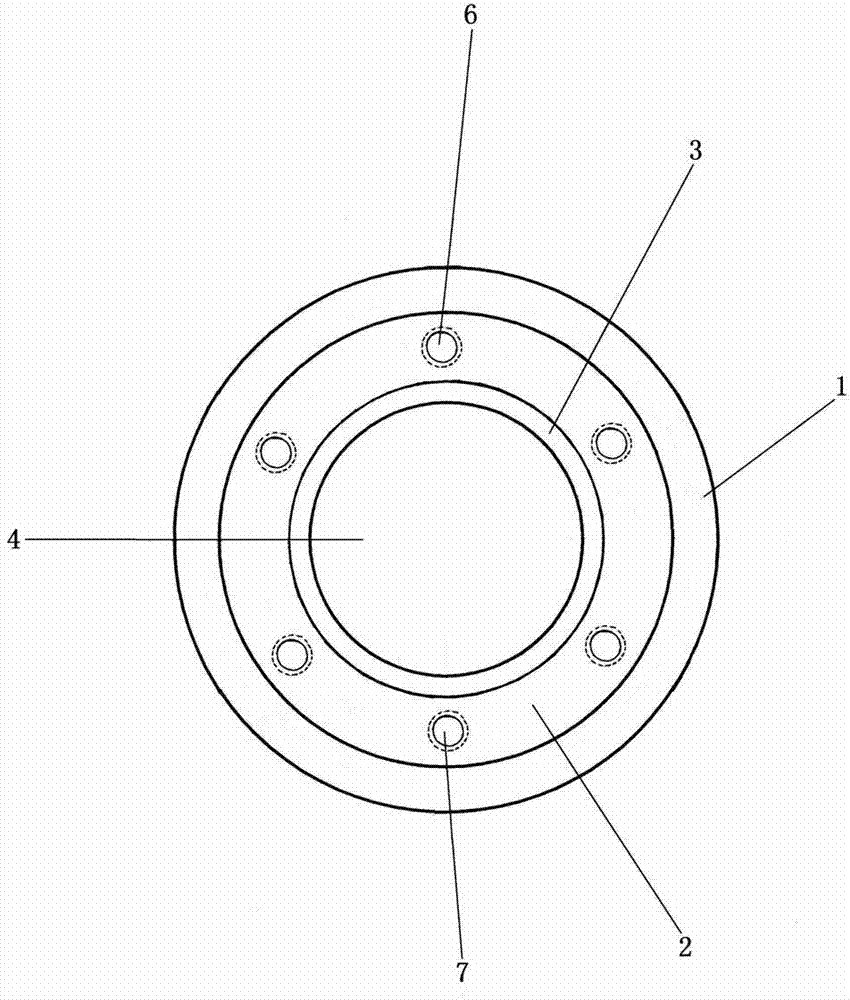

[0010] The grinding head mounting seat of the groove grinding machine includes a metal seat, a round through hole and a threaded hole. It is characterized in that the metal seat 1 is a cylindrical metal seat, placed horizontally, and the diameter of the outer circumference of the metal seat 1 is 215mm, left and right The length is 355㎜; at the center of the left circular surface of the metal base 1, drill a circular through hole 4 to the right. The diameter of the circular through hole 4 is 110㎜. The shape surface has been drilled through the right circular surface of the metal seat 1, and the circular through hole 4 is concentric with the outer circumference of the metal seat 1; on the left circular surface of the metal seat 1, a left circular hole 2 is drilled, and the left circular The diameter of hole 2 is 155㎜, and the length of left and right is 15㎜; the left round ho...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com