Tool and operation method thereof

A technology of tools and tool components, applied in the direction of motor tools, manufacturing tools, wrenches, etc., can solve problems such as user neglect of update configuration, user error input, tools not operating as expected, etc., to achieve energy supply and simplify applications and transport effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

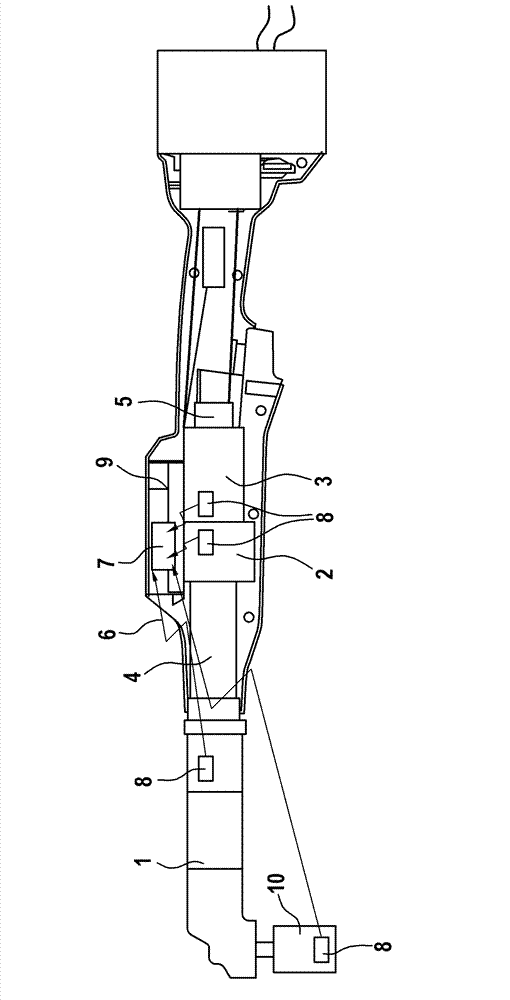

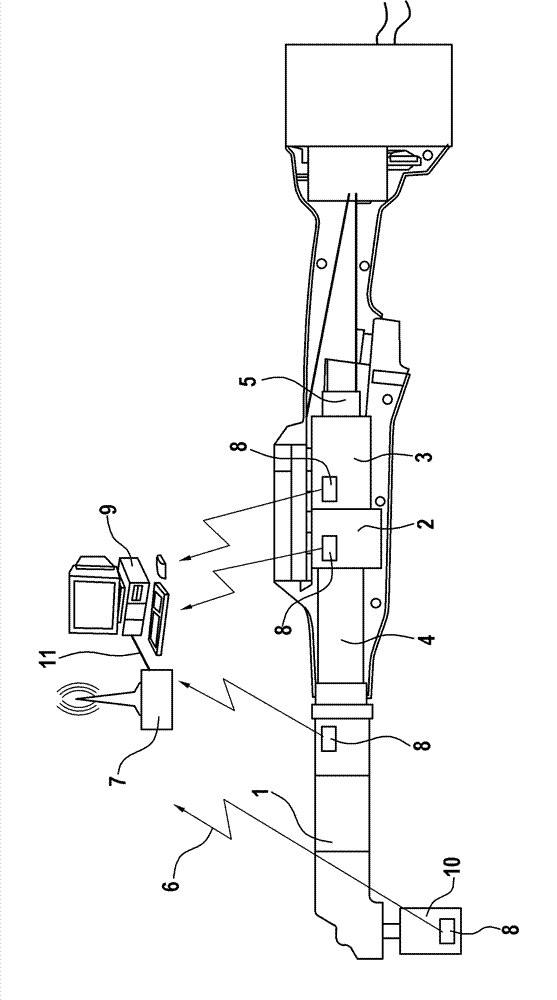

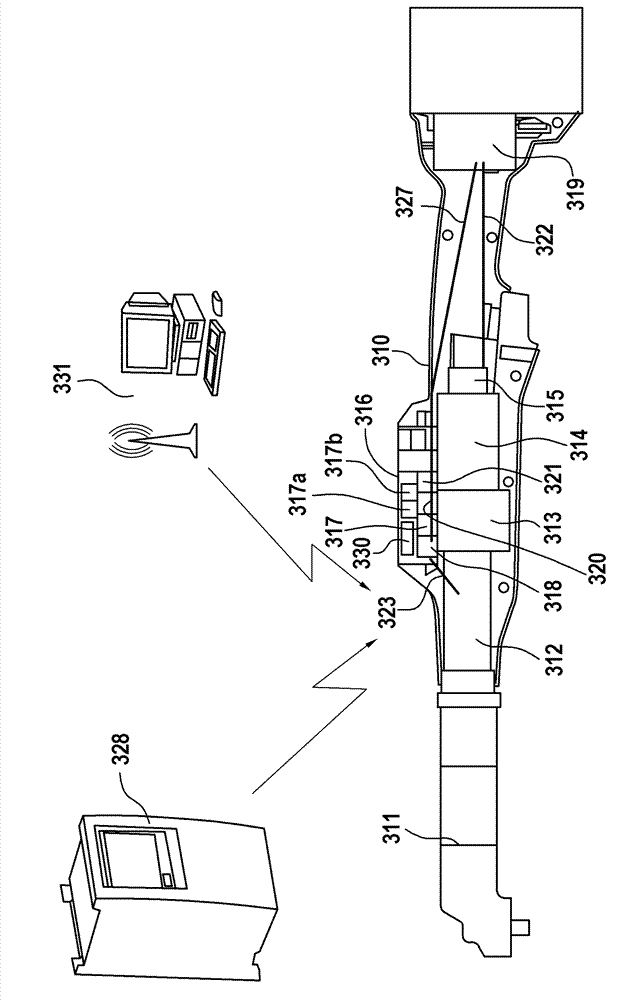

[0030] figure 1 An example of a battery-operated screw spindle is shown, and the screw spindle also includes a device for running on the power grid. The screw spindle includes a first tool assembly in the form of a drive mechanism 3 and a second tool assembly in the form of a driven mechanism 1, and preferably includes other tools such as, for example, the transmission mechanism 2, the torque sensor 4, and the rotor position detector 5. The components, which are mutually arranged inside the housing and connected to each other, enable the driven mechanism 1 to be driven by means of the drive mechanism 3.

[0031] The tool assembly 1-5 includes a self-contained and wirelessly working data communication unit 8 with a memory and an energy supply unit. The energy supply unit is implemented in such a way that the energy supply unit can be inductively coupled to an external energy source to provide the energy required for operating the data communication unit 8.

[0032] In addition, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com