Paper product bonding servo rectification system of cover and tray carton machine and covering making machine

A technology of cover machine and box, which is applied to paper/cardboard containers, container manufacturing machinery, containers, etc., can solve problems such as jamming, tilting of the face paper of the box, and unevenness between the cardboard and the face paper.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

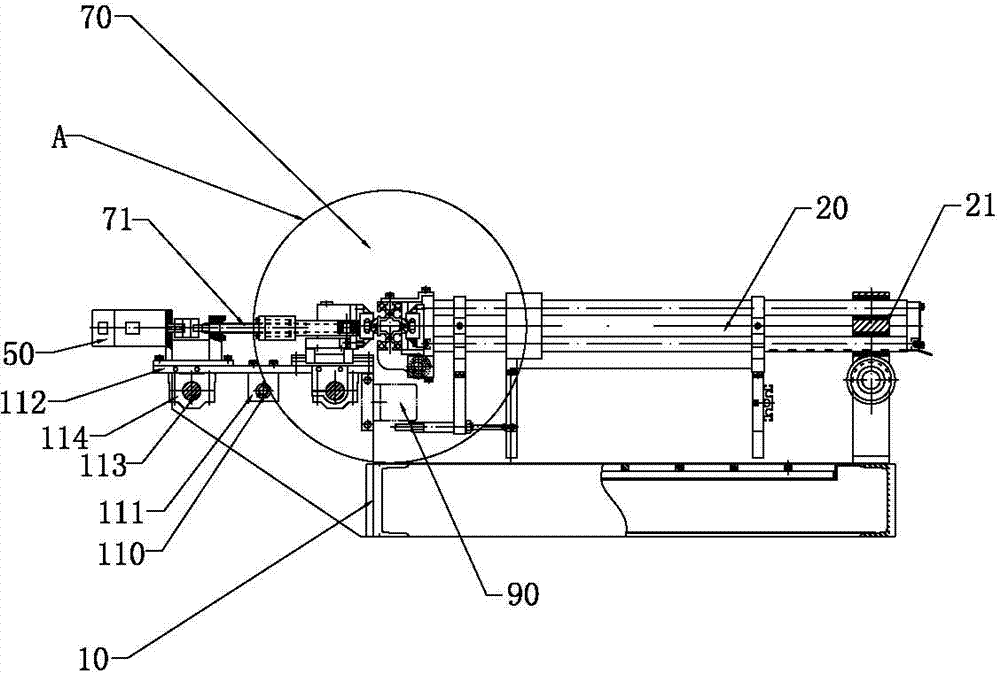

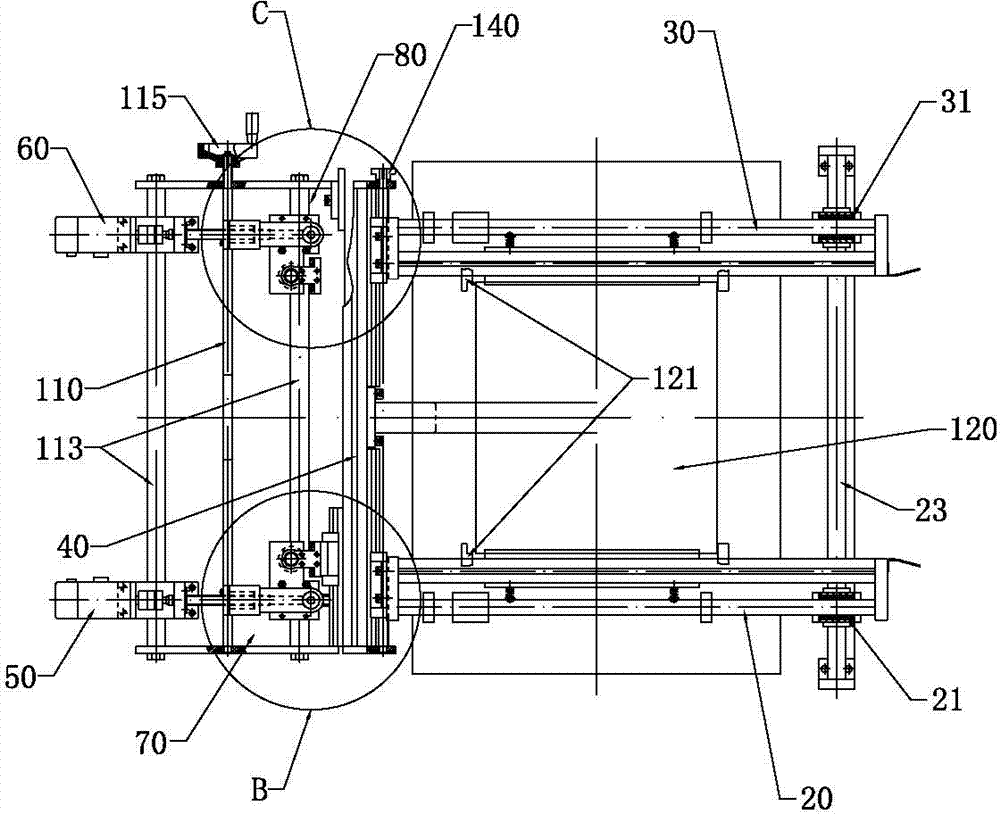

[0043] The present invention will be described in detail below in conjunction with the accompanying drawings, wherein, the orientation words in the present invention are up, down, front, back, left, and right. figure 2 as the benchmark.

[0044] Such as Figure 1 to Figure 7 As shown, the paper bonding servo correction system of the heaven and earth box machine and the cover machine of the present invention includes a frame 10, and the two sides above the frame 10 are respectively provided with a left movable rod 20 and a right movable rod 30;

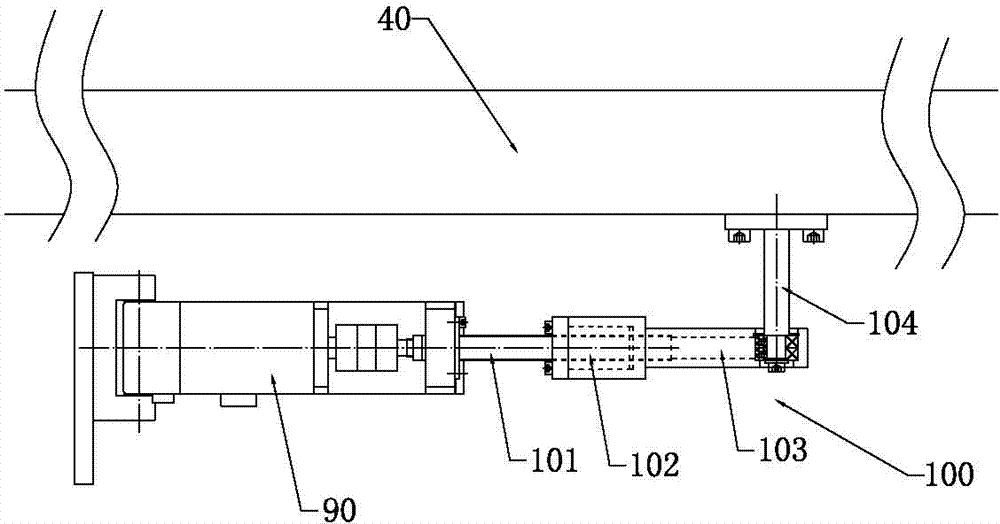

[0045]The front end of the left movable rod 20 and the front end of the right movable rod 30 are provided with a linear slide rail 40, and the linear slide rail 40 is slidingly connected with a first left slider 41, a second left slider 42, a first right slider (Fig. Not marked in, the installation method of the first right slider is the same as the first left slider 41) and the second right slider 43, the left movable rod 20, the ri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com