Sanitary ceramic semi-finished product crack-repairing slurry and preparation method thereof

A technology for sanitary ceramics and semi-finished products, applied in the field of semi-finished sanitary ceramics repairing mud and its preparation, to achieve the effects of improving product qualification rate, reducing environmental pollution, and increasing toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] A method for preparing crack repairing mud for semi-finished products of sanitary ceramics, comprising the steps of:

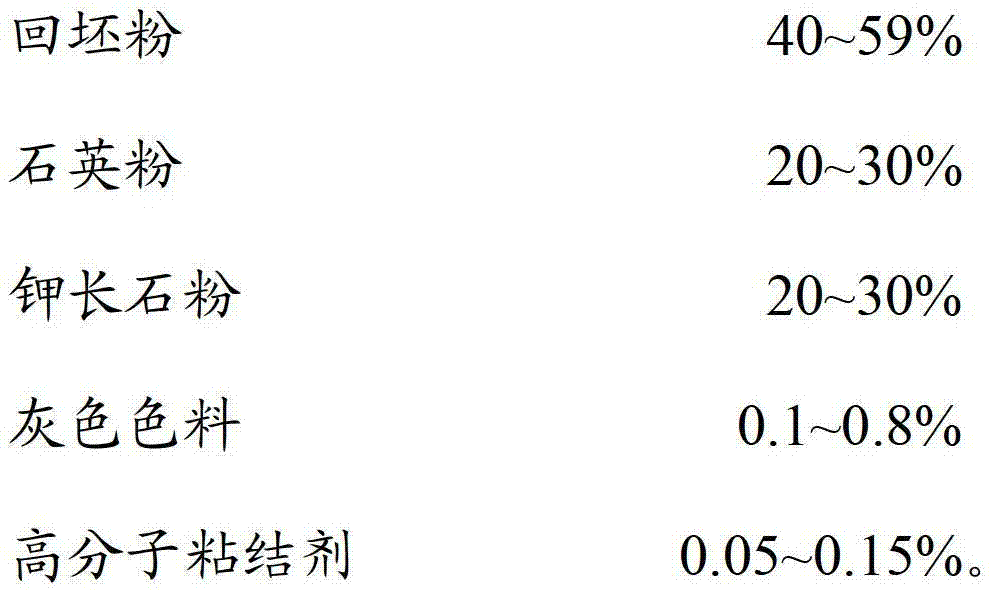

[0046] (1) Prepare basic mud, that is, weigh each component according to the following weight percentage:

[0047]

[0048] Fully mix the above components with water and ball mill to obtain the basic mud. The concentration of the basic mud is 350-360g / 200mL, and the particle size is <10um: 56-60%;

[0049] (2) Weigh 85-95 parts by weight of the above basic mud and 5-15 parts by weight of high-temperature refractory cotton, fully stir and mix evenly, and then dehydrate to obtain the semi-finished sanitary ceramic crack repair mud; the above-mentioned high-temperature refractory cotton is standard silicon Acid aluminum fiber cotton (1260°C), the fiber length of which is pre-treated to be 2-4mm;

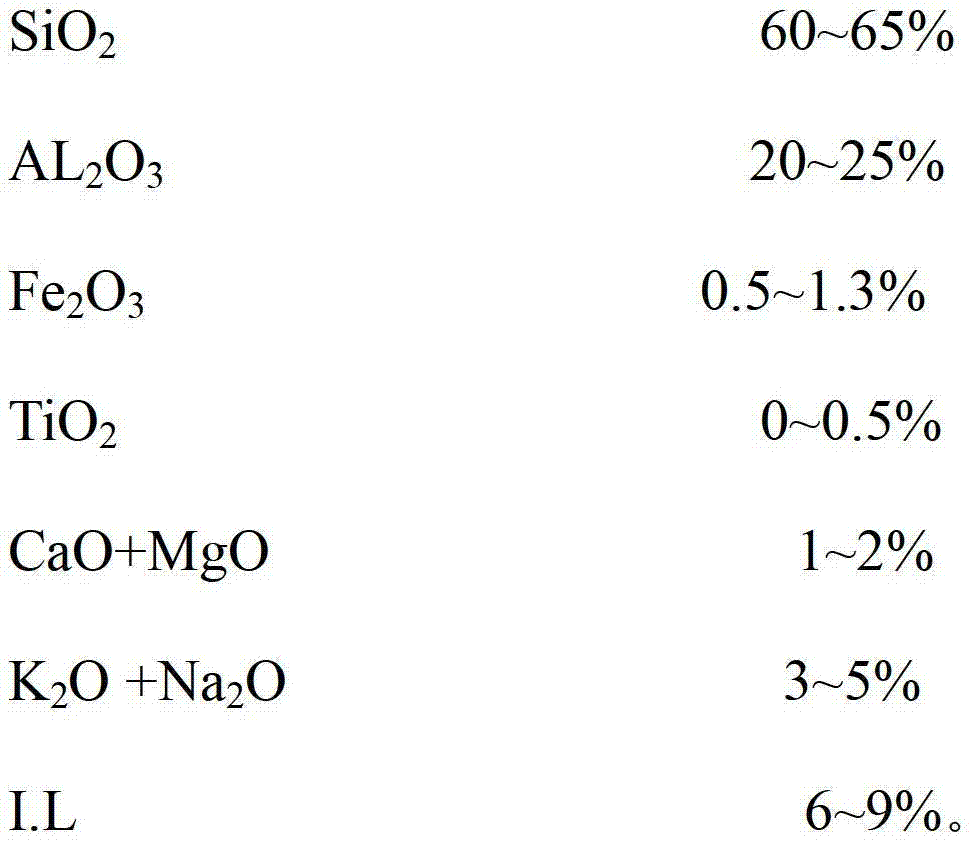

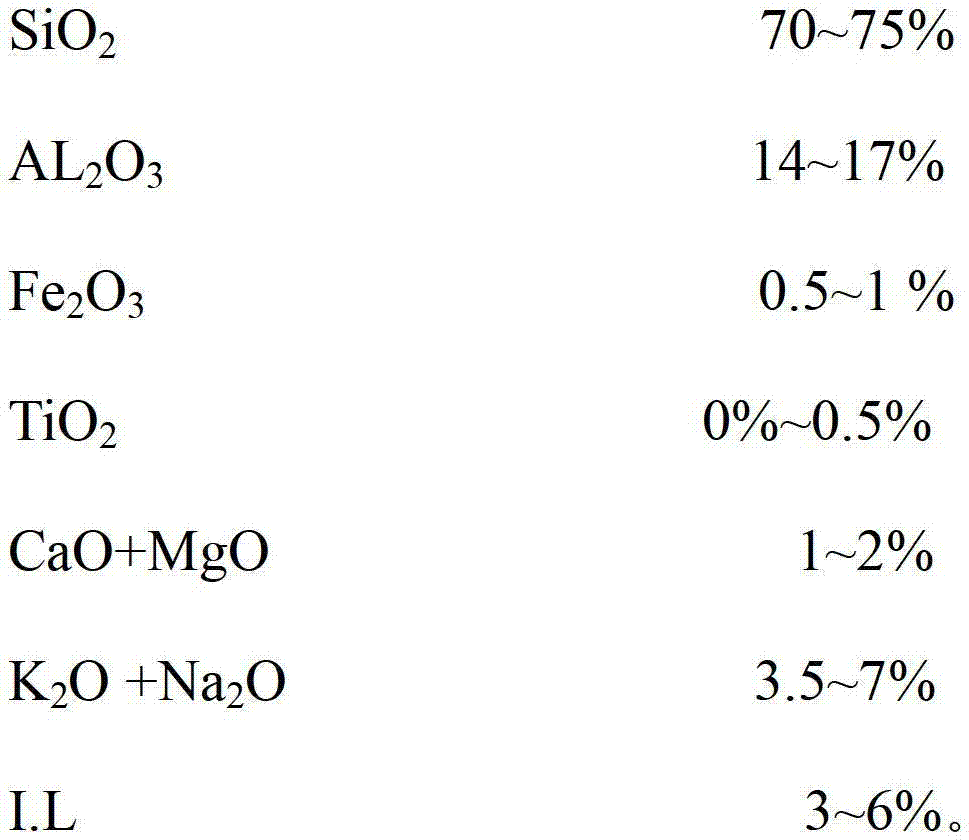

[0050] Above-mentioned back compact powder comprises the component of following percentage by weight:

[0051]

[0052] The above-mentioned regenerated p...

Embodiment 2

[0060] (1) Use a blade to scrape the part that needs to be repaired on the semi-finished sanitary ceramics until there is no crack, and wet the part with water;

[0061] (2) Use the crack repairing mud to make mud strips to repair the above-mentioned treated parts that need to be repaired, and compact them to avoid internal air bubbles;

[0062] (3) After the repair is completed, dry the repaired part and polish it until there is no obvious concave-convex feeling compared with other parts;

[0063] (4) Glaze the part to be repaired after drying to avoid poor glazing in the later glazing process;

[0064] (5) After brushing the glaze, it can be glazed according to the normal product and fired at 1190℃~1210℃.

[0065] In addition, according to different crack lengths, brushing repair and mud strip repair can be selected for repair. The specific implementation is as follows:

[0066]

[0067] Note: When scraping the cracked part, it must be scraped to the place where there i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com