Wear-resistant sole material

A sole material and raw material technology, applied in the field of wear-resistant sole materials, can solve the problems of low mechanical properties of tensile strength, poor resilience, poor wear resistance of wear-resistant soles, etc., and achieve excellent wear resistance, excellent anti-skid performance, The effect of wet skid resistance coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

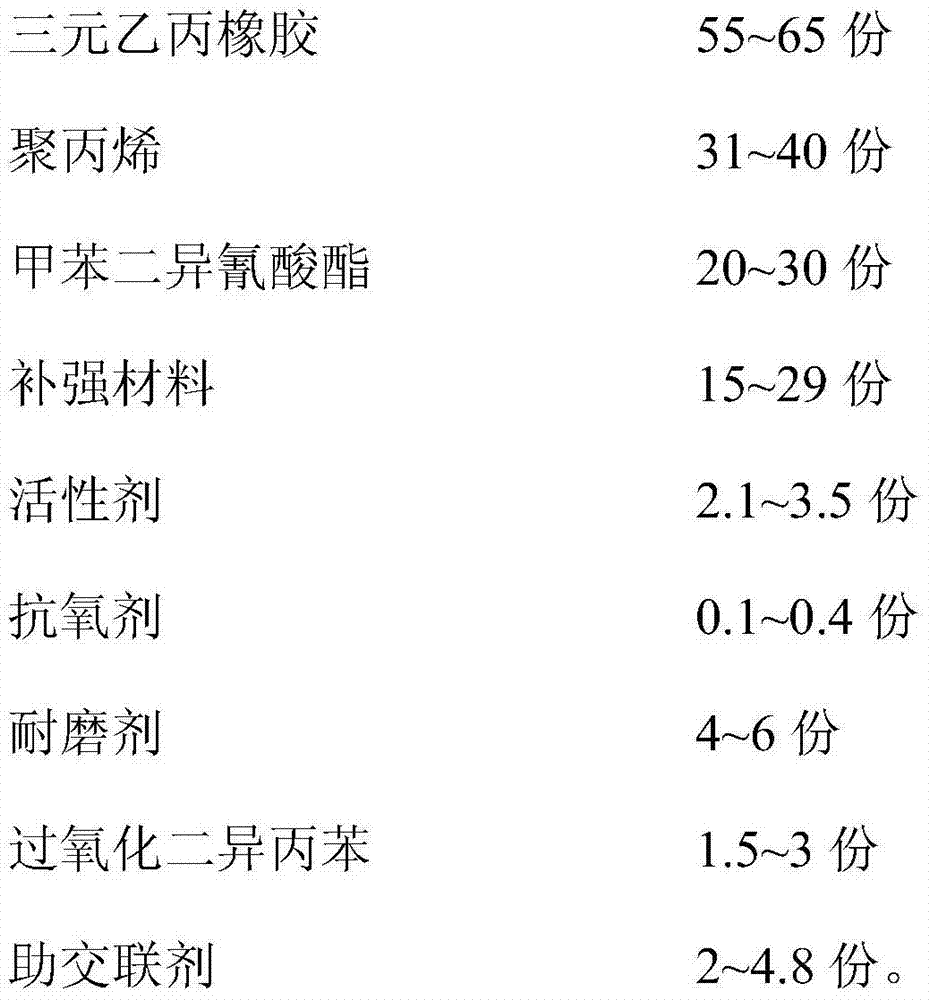

[0031] A kind of wear-resistant shoe sole material, it comprises following raw material by weight part:

[0032]

[0033]

[0034] The antioxidant is composed of primary antioxidant and auxiliary antioxidant.

[0035] The main antioxidant is antioxidant 1010.

[0036] The secondary antioxidant is triphenyl phosphite (TPP).

[0037] The anti-wear agent is graphite.

[0038] The auxiliary crosslinking agent is acrylic acid.

[0039] The reinforcing agent is selected from carbon black N234.

[0040] Described active agent selects stearic acid for use.

Embodiment 2

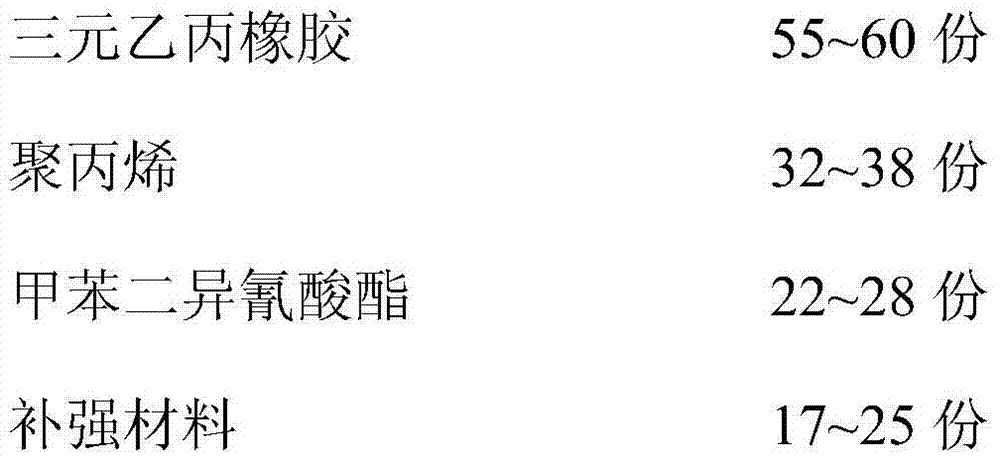

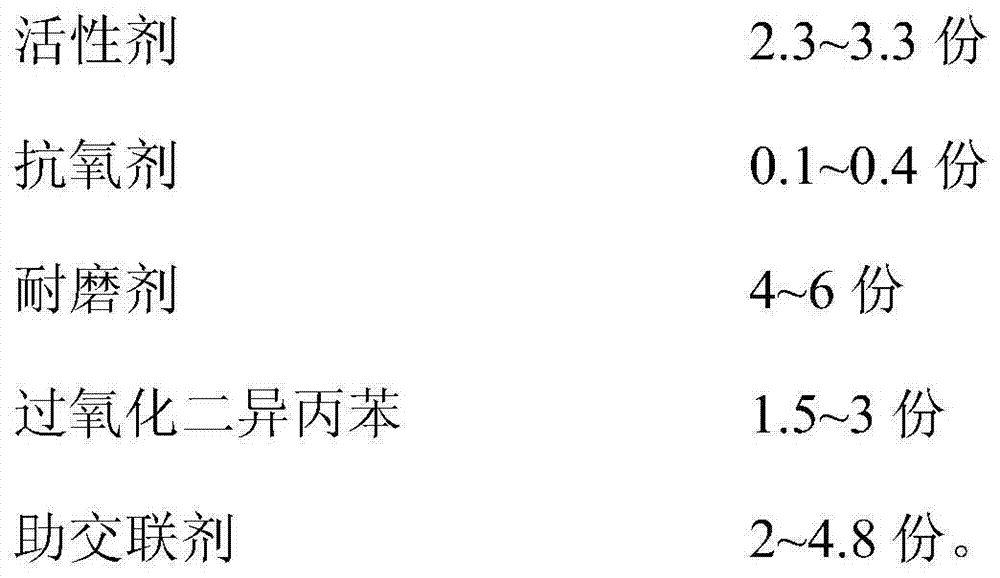

[0042] A kind of wear-resistant shoe sole material, it comprises following raw material by weight part:

[0043]

[0044] The antioxidant is composed of primary antioxidant and auxiliary antioxidant.

[0045] The main antioxidant is antioxidant BHT.

[0046] The secondary antioxidant is phenyl diisodecyl phosphite (PDDP).

[0047] The anti-wear agent is graphite.

[0048] The auxiliary crosslinking agent is styrene.

[0049] The reinforcing agent is selected from carbon black N330.

[0050] Described active agent selects stearic acid and zinc stearate for use.

Embodiment 3

[0052] A kind of wear-resistant shoe sole material, it comprises following raw material by weight part:

[0053]

[0054] The antioxidant is composed of primary antioxidant and auxiliary antioxidant.

[0055] The main antioxidant is antioxidant 1790.

[0056] The auxiliary antioxidant is selected from antioxidant 168.

[0057] The anti-wear agent is graphite.

[0058] The auxiliary crosslinking agent is acrylic acid and styrene.

[0059] The reinforcing agent is selected from a mixture of carbon black N234, carbon black N220 and carbon black N330.

[0060] The active agent is stearic acid or / and zinc stearate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com