Fermentation reactor and preparation method for dynamically culturing and preparing ordered bacteria cellulose

A technology of bacterial cellulose, dynamic culture, applied in specific-purpose bioreactors/fermenters, microorganism-based methods, biochemical equipment and methods, etc., can solve the problems of low yield, complex process, etc., to achieve low energy consumption , The effect of simple process, strong structure and output controllability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

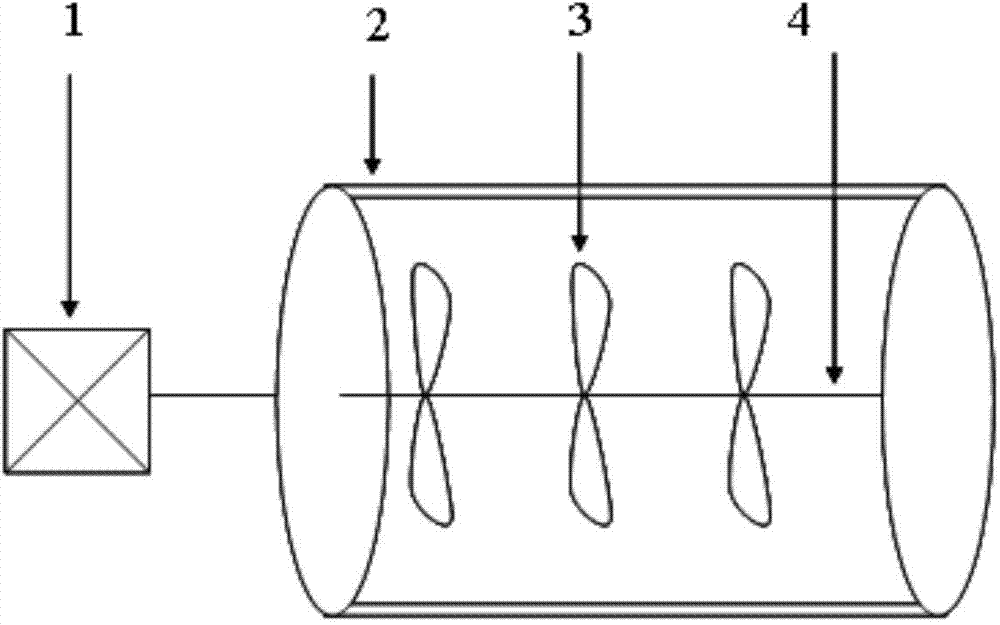

[0031] A culture method in which a mechanical transmission device is used to drive the relative movement of the fermentation broth along the inner wall of the semi-permeable membrane, such as figure 1 shown.

[0032] 1. The height of the fermentation reactor is designed to be 100mm, and the diameter is 90mm. The side wall material of the main container is a 1.5mm thick silica gel plate. The blade length in the power unit is 20mm, and the central shaft is connected to a frequency conversion motor.

[0033] 2. Preparation of medium: add glucose 25g / L, yeast powder 7.5g / L, peptone 10g / L and disodium hydrogen phosphate 10g / L into a beaker filled with 1000ml ultrapure water in turn, and stir until it is completely dissolved; Glacial acetic acid adjusts the pH value of the system to between 4 and 5. After high-temperature sterilization at 115°C for 30 minutes, it was taken out and used as a medium for bacterial growth.

[0034] 3. Bacteria inoculation in the culture medium: cool t...

Embodiment 2

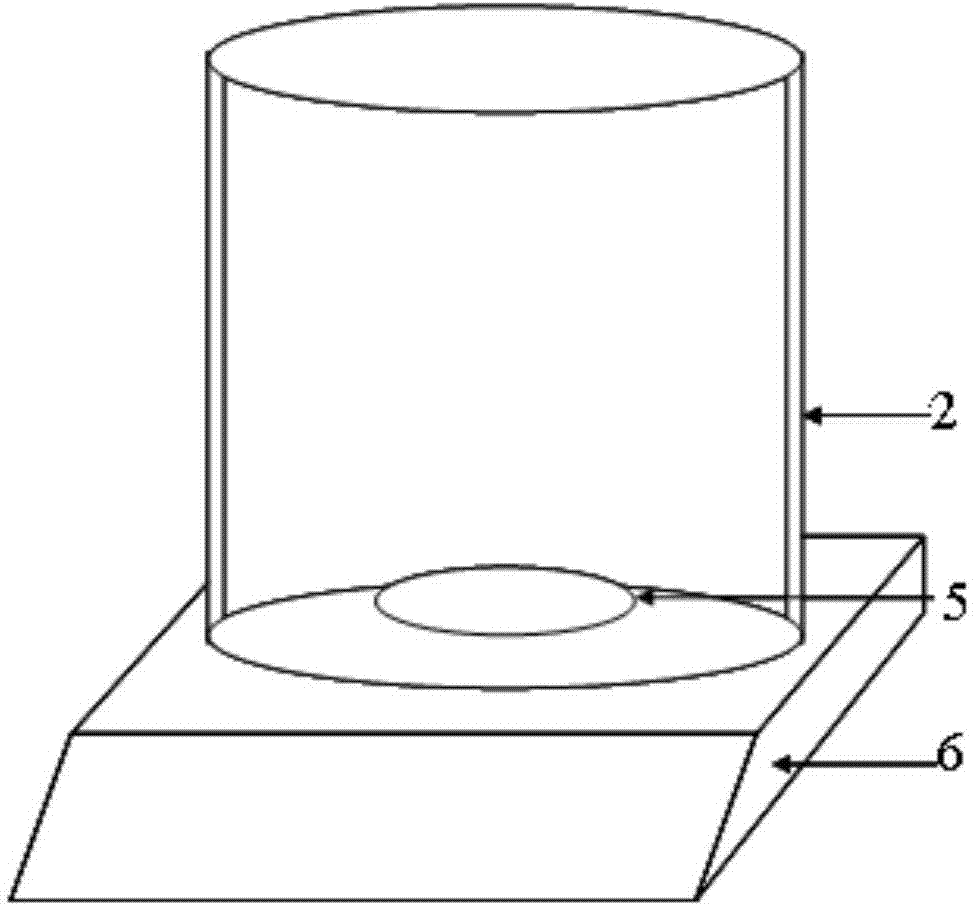

[0040] A culture method in which a magnetic stirring device is used to drive the relative movement of the fermentation broth along the inner wall of the semi-permeable membrane, such as figure 2 shown.

[0041] The preparation method step of present embodiment 2 is as follows:

[0042] 1. The height of the fermentation reactor is designed to be 100 mm, and the diameter is 90 mm. The side wall material of the main container is a silica gel plate with a thickness of 1.5 mm, and a magnet with a length of about 30 mm is selected.

[0043] 2. Preparation of culture medium: as in Example 1.

[0044] 3. Culture medium inoculated with bacteria: as in Example 1.

[0045] 4. Dynamic fermentation: Fill the entire reaction vessel with the culture solution inoculated with bacteria, and seal it with Vaseline after removing air bubbles. Adjust the rotating speed of the magnetic stirrer to about 100r / min, place the fermentation reactor in a well-ventilated constant temperature incubator a...

Embodiment 3

[0048] A culture method in which a magnetic stirring device is used to drive the relative movement of the fermentation broth along the inner wall of the semi-permeable membrane, such as figure 2 shown.

[0049] The preparation method steps of present embodiment 3 are as follows:

[0050] 1. The height of the fermentation reactor is designed to be 70mm and the diameter is 60mm. The side wall material of the main container is a silica gel plate with a thickness of 1.5mm, and a magnet with a length of about 30mm is selected.

[0051] 2. Preparation of culture medium: as in Example 1.

[0052] 3. Culture medium inoculated with bacteria: as in Example 1.

[0053] 4. Dynamic fermentation: Fill the entire reaction vessel with the culture solution inoculated with bacteria, and seal it with Vaseline after removing air bubbles. Adjust the rotating speed of the magnetic stirrer to about 300r / min, place the fermentation reactor in a well-ventilated constant temperature incubator at 30...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap