Integral ballast bed track structure for medium and low speed maglev transportation

An integral, maglev technology, applied in the field of rail transit, can solve the long-term effectiveness and integrity of unfavorable track high ride comfort rail components, the inability to realize independent and precise ride comfort adjustment of F-shaped rail surfaces, and the difficulty in achieving high Accuracy requirements and other issues, to achieve the effect of suppressing the resonance phenomenon of the train rail, improving the mechanical characteristics of the structure, and facilitating the evacuation of passengers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

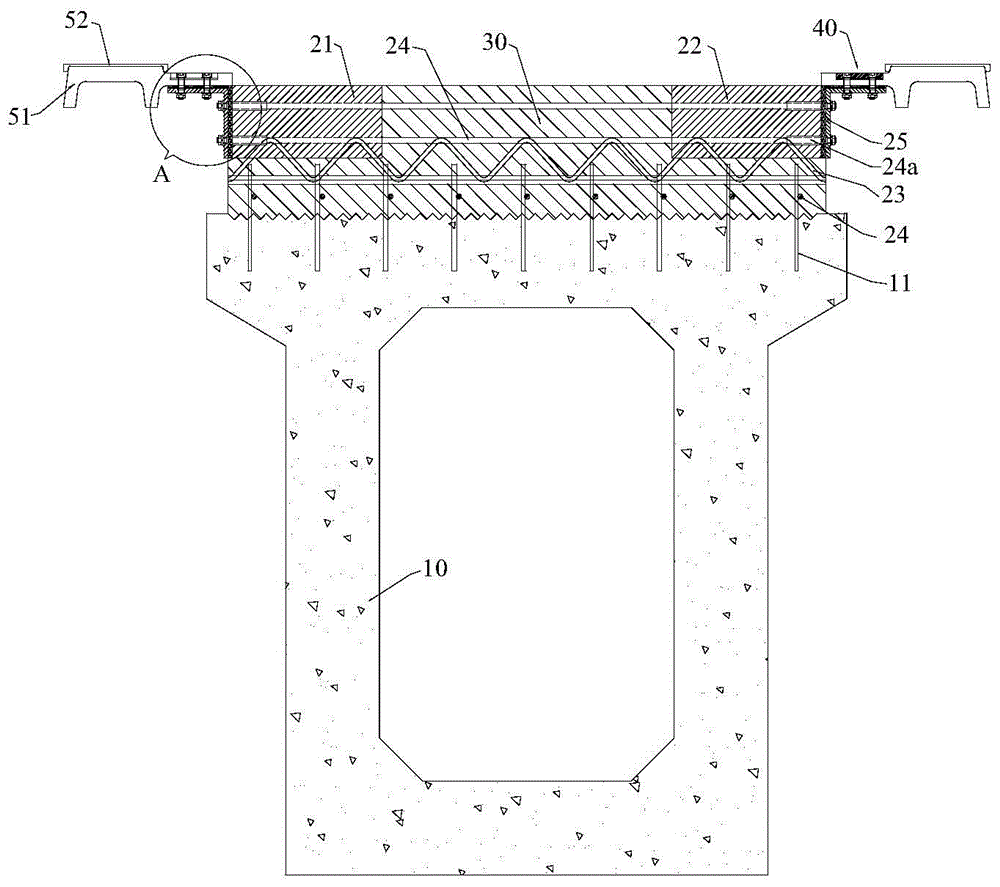

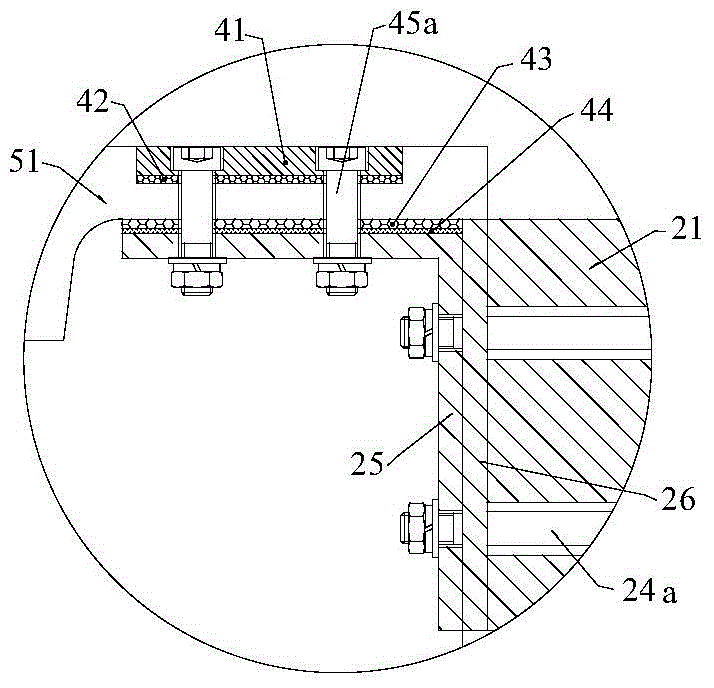

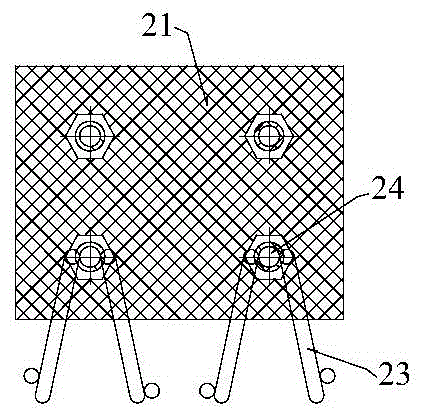

[0022] refer to figure 1 , figure 2 and Figure 6 , the integrated ballast bed track structure for medium and low-speed maglev transportation of the present invention includes a track beam 10, an F-shaped rail 51 and a fastener system. It also includes: support adjustment units arranged at intervals along the extending direction of the track beam 10, each support adjustment unit includes a left reinforced concrete connector 21, a right reinforced concrete connector 22, and a steel bar truss 23 and a through The long steel bar 24; the integral track bed slab 30 is integrally poured between the inner sides of the left reinforced concrete connector 21 and the right reinforced concrete connector 22 and between the bottom surface and the top surface of the track beam 10, and through the connecting structure and The track beam 10 is connected as a whole; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com