Under-pressure drill tripping method used under top drive drilling machine

A technology of top drive and drilling rig, applied in the direction of drill pipe, drill pipe, earthwork drilling, etc., to achieve the effect of simple design, reducing labor intensity and ensuring personal safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

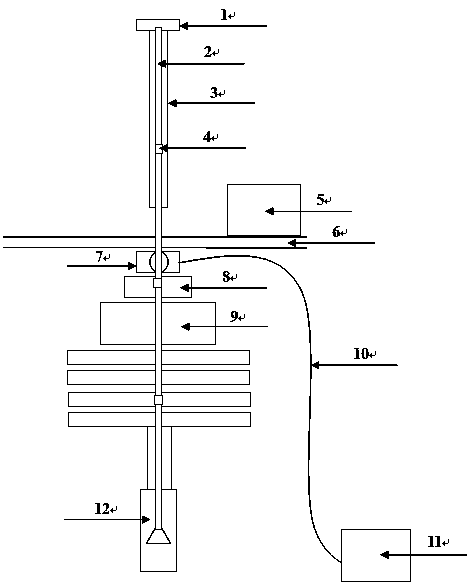

[0035] Refer to the attached figure 1 , the best implementation mode of the present invention is, comprises the following steps:

[0036] Install hydraulic slips under the drill floor, and measure the pressure of the wellhead that needs to be tripped under pressure; when the tested wellhead pressure is less than or equal to 5Mpa, use the top drive 11 to connect the drilling tool 2, and use the top drive 11 to implement under pressure When tripping out, the number of drilling tools 2 that are lifted or lowered is 1-3; when the number of drill tools 2 that is lifted or lowered reaches 1-3, the hydraulic slips arranged under the drill floor are activated, Make the hydraulic slips clamp the drilling tool 2, and the clamping force of the hydraulic slips is ≥ 3T; when starting the top drive 11 and lifting the drilling tool 2, the drilling tool 2 stuck at the wellhead is separated, and the unloaded The drilling tool 2 is placed on the rack; when the drilling tool 2 is lowered, the d...

Embodiment 2

[0037] Embodiment 2, the mode of pulling out drilling tool 2 in the well:

[0038] First test the wellhead with a pressure of 5MPa, use the top drive 11 to prevent the drilling tool 2 from going up, pull out two 9m-long drill collars at the wellhead, slowly lift them to the drill floor 6, and their joints are located 20cm~100cm above the drill floor 6, and open The hydraulic (pneumatic) pressure switch activates the hydraulic (pneumatic) slips and clamps the drill collar. At this time, the camera installed near the hydraulic (pneumatic) slips is used to monitor the opening and closing of the slips and confirm the clamping. After tightening, use iron driller or hydraulic tongs to disassemble the pipe string on the drill floor 6, remove the disassembled drill collar, and then lower the top drive 11 to the vicinity of the drill floor 6, and then Connect the remaining drill collars in the well, loosen the hydraulic (pneumatic) dynamic slips, and then use the top drive 11 to lift t...

Embodiment 3

[0039] Embodiment 3, the drilling tool 2 is lowered into the well:

[0040] Test the wellhead with a pressure of 3MPa. Use the camera installed near the hydraulic (pneumatic) slips to monitor the opening and closing of the slips. After confirming the release, use the top drive 11 to slowly lower a column (3 drill collars) , until the drill collar joint is 620cm~100cm above the drill floor, stop lowering, turn on the hydraulic (air) pressure switch, start the hydraulic (air) slips, and clamp the drill collar. After confirming the clamping, release the top drive 11, Top drive 11 connects a new column and moves it to the wellhead, uses iron drillers or hydraulic tongs to connect with the drill collar in the well, then releases the hydraulic (gas) slips, and uses top drive 11 to lower the new column. Slowly run into the well and repeat the operation until 5 to 10 columns of drilling tools 2 are scheduled to be lowered into the well.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com