Shallow tunneling method for pipe-proof-supporting structure combined system

A technology of supporting structure and shallow burial, which is applied in shaft lining, tunnel lining, underground chambers, etc., can solve the problems of high safety risk, significant social impact, and difficult to control land subsidence, and achieves broad market promotion value, Less interference with urban production and life, ensuring the effect of the road

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Below in conjunction with accompanying drawing, the present invention is described in further detail:

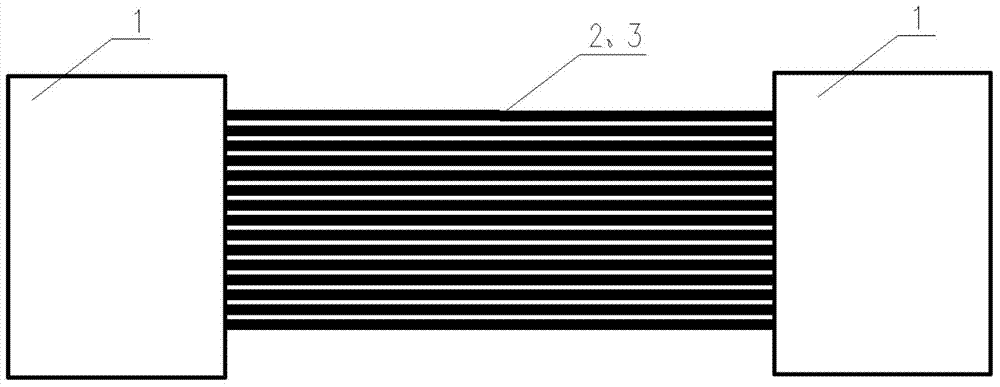

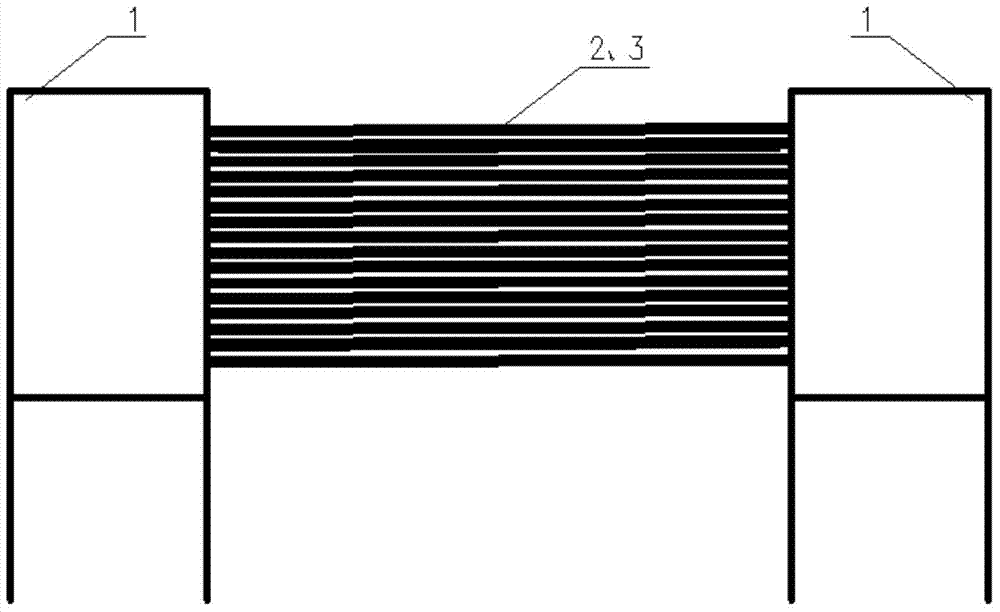

[0032] according to Figure 1~9 It can be seen that for the shallow-buried large-section underground structure in saturated soft soil stratum, this method can effectively excavate the underground structure to retain soil and water, reduce the disturbance to the adjacent soil during excavation, and correspondingly reduce the deformation of the surrounding soil. To achieve strict control of settlement during excavation, without affecting ground activities, and maintaining the normal functions of upper buildings (structures), roads and pipelines, the steps are:

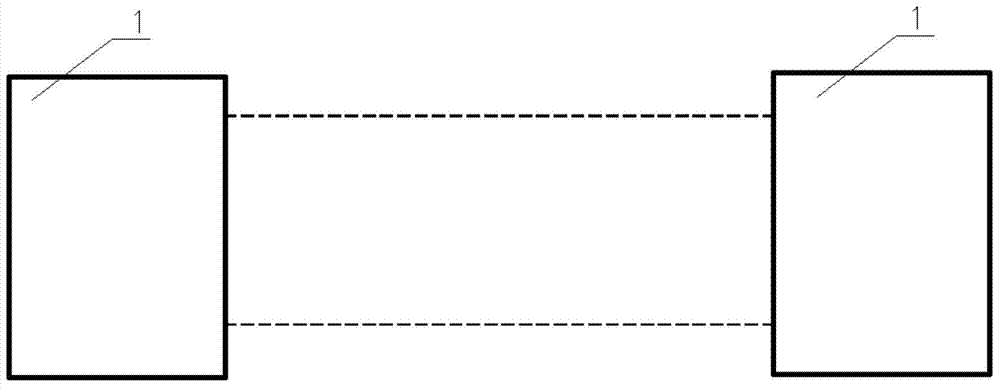

[0033] In step 1, two vertical working wells 1 are formed at both ends of the underground main structure 10 . The section shape of the underground main structure 10 is an ellipse composed of multiple circular arcs, which is a reinforced concrete structure and is the main permanent force-bearing structure for sh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com