Packing method and detecting method of gel chromatography column

A gel chromatography column and column packing technology, applied in the field of chromatography, can solve the problems of toxic reagents, volatile, product quality and safety impact, etc., and achieve the effect of improving column packing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

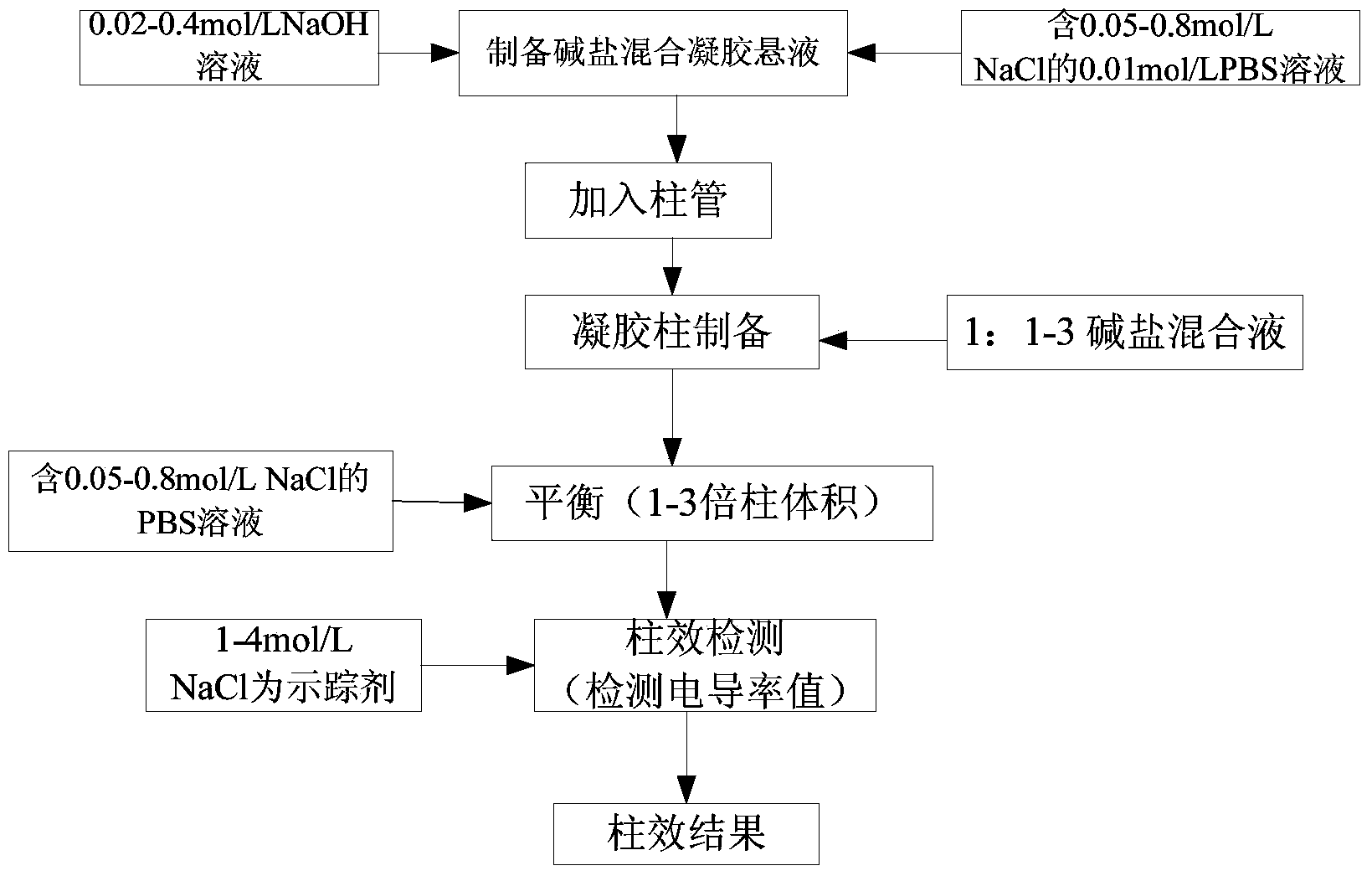

[0036] The gel was Sephacryl S-400HR produced by GE Company. see process figure 1 .

[0037] 1) Preparation of gel suspension: use 0.02mol / L NaOH solution and 0.01mol / LPBS (containing 0.05mol / LNaCl, pH7.2) solution 1:1 mixed alkali salt buffer solution to homogenize the gel, gel and alkali salt The ratio of buffer is 1:1 to get a gel suspension

[0038] 2) Column packing: Add purified water with a liquid level of 1cm at the bottom of the column tube, then fill the column with gel suspension, install the column head of the chromatography column, and pump 0.02mol / L NaOH solution with a constant pressure of 1.0bar 0.01mol / LPBS (containing 0.05mol / L NaCl, pH7.2) solution 1:1 mixed alkali-salt solution, constant pressure until the gel height remains constant, the prepared gel column height is 65cm; proceed to the next step;

[0039] 3) Equilibration: Equilibrate 1 times the column volume with 0.01mol / L PBS (containing 0.05mol / L NaCl, pH7.2) buffer solution, and the equilibrium f...

Embodiment 2

[0047] 1) Preparation of gel suspension: Mix 0.4mol / L NaOH solution and 0.01mol / LPBS (containing 0.8mol / L NaCl, pH7.4) solution 1:3 to homogenize the gel; the ratio of gel to alkali salt buffer solution 1:3; get a gel suspension

[0048]2) Packing the column: Add purified water with a liquid level of 2cm at the bottom of the column tube, fill in the gel suspension, install the column head, and then pump in 0.4mol / L NaOH solution and 0.01mol / L PBS (containing 0.8mol / L NaCl, pH 7.4) solution 1:3 mixed alkali-salt buffer to prepare a gel column, the constant pressure is 1.0bar to the same height, and the prepared gel column is 70cm high;

[0049] 3) Equilibration: equilibrate 3 times the column volume with 0.01mol / L PBS (containing 0.8mol / LNaCl, pH7.4) buffer solution, and the equilibrium flow rate is 35cm / h;

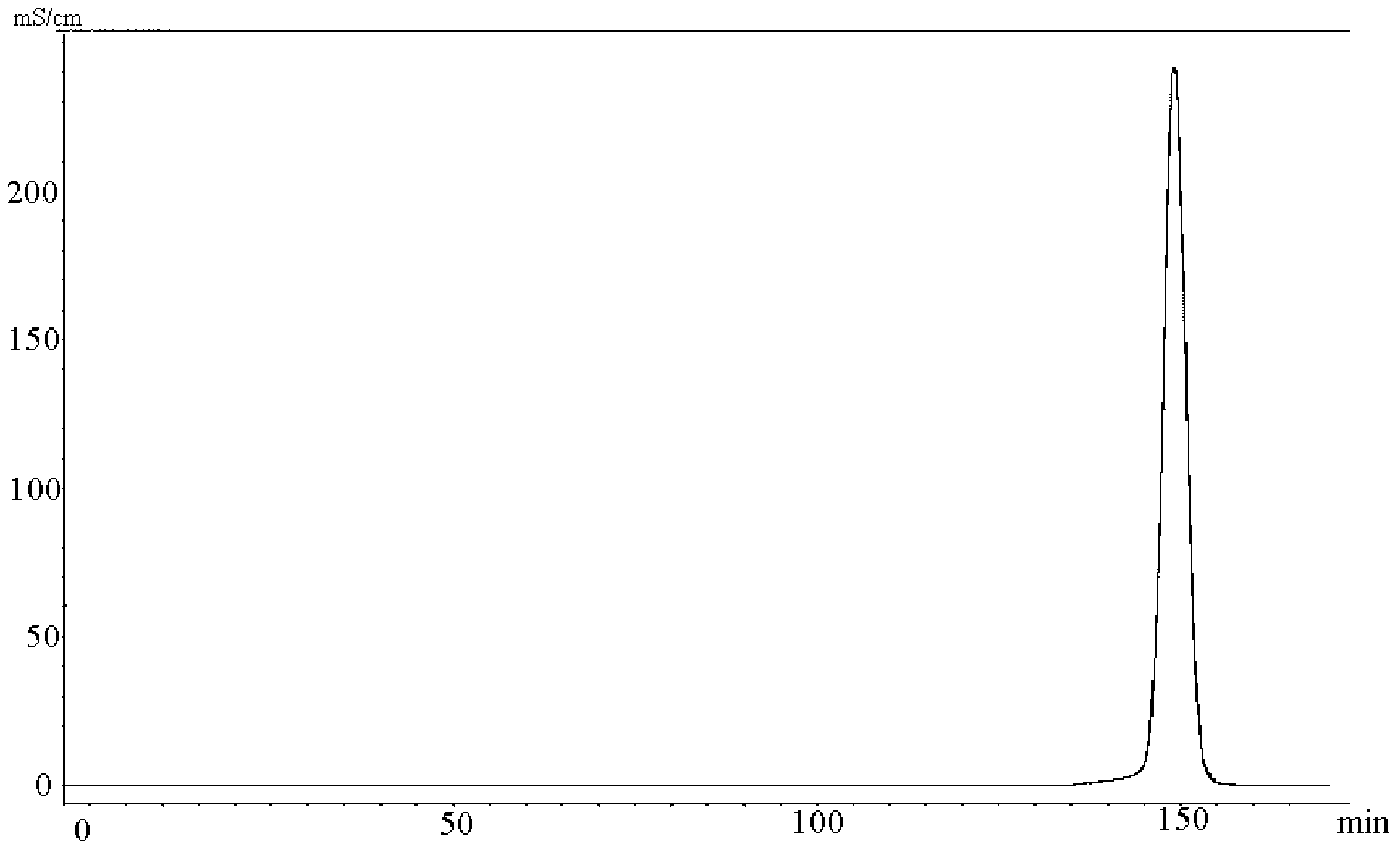

[0050] 4) Column efficiency detection:

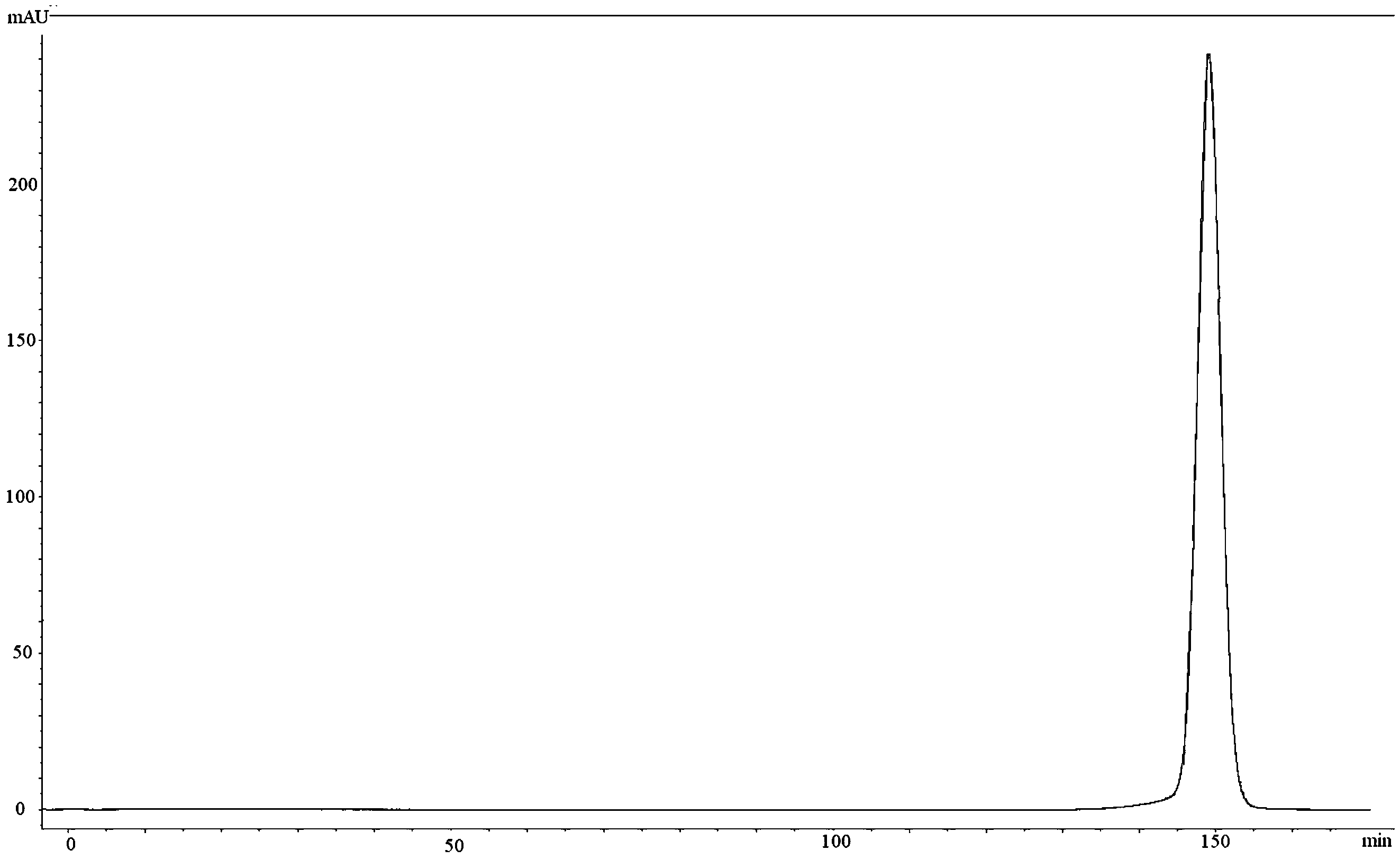

[0051] a) Acetone control: 2% acetone solution was prepared with purified water as a tracer, the loading volume was 4% of the co...

Embodiment 3

[0057] 1) Preparation of gel suspension: mix 0.2mol / L NaOH solution and 0.01mol / LPBS (containing 0.3mol / L NaCl, pH7.3) solution 1:1.5 to homogenize the gel, and the ratio of gel to alkali salt buffer is 1: 1.5; Obtain gel suspension;

[0058] 2) Packing column: Add purified water with a liquid level of 4cm at the bottom of the column tube, fill in the gel suspension, install the column head, and pump in 0.2mol / L NaOH solution and 0.01mol / LPBS (containing 0.3mol / L NaCl, pH 7.3) solution 1:1.5 mixed alkali-salt solution to prepare a gel column, the constant pressure is 1.0bar to the height unchanged, and the prepared gel column is 72cm high;

[0059] 3) Equilibration: Equilibrate 1.5 times the column volume with 0.01mol / L PBS (containing 0.3mol / LNaCl, pH7.3) buffer solution, and the equilibrium flow rate is 34cm / h;

[0060] 4) Column efficiency detection:

[0061] a) Acetone control: 2% acetone solution was prepared with purified water as a tracer, the loading volume was 2% of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com