A virtual human-machine interface system and construction method based on machine vision

A man-machine interface and machine vision technology, applied in the direction of comprehensive factory control, electrical program control, etc., to achieve the effect of ensuring no leaks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

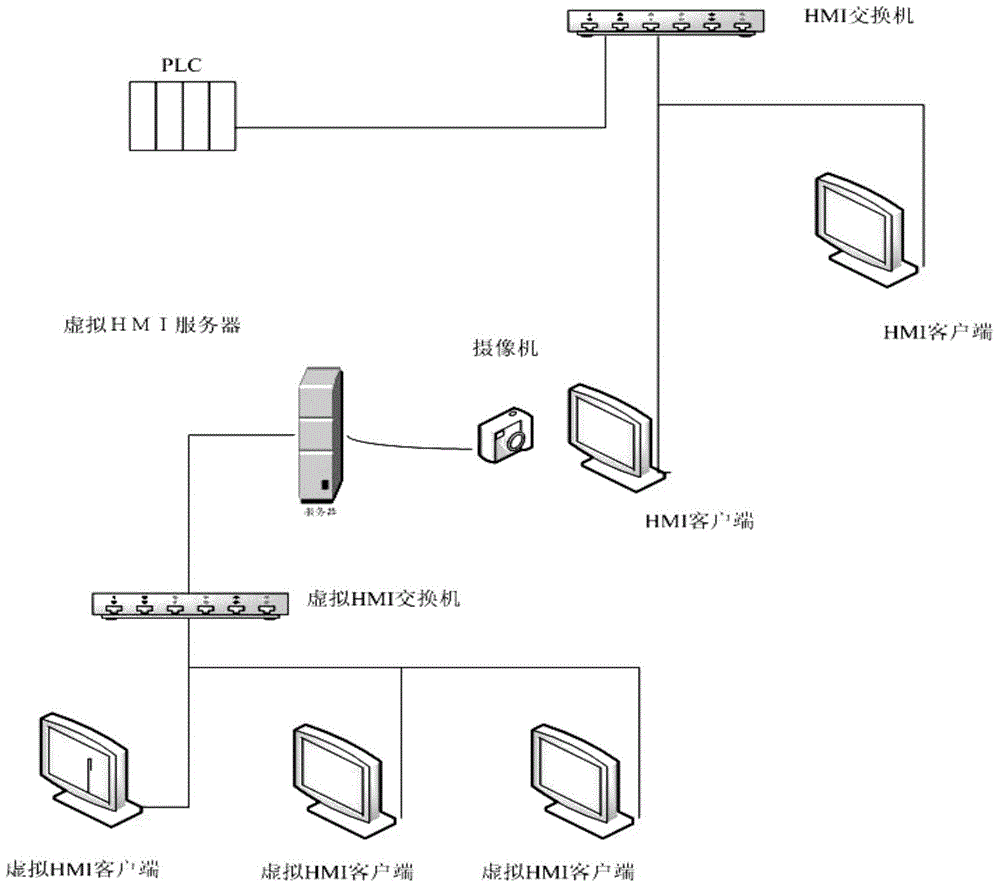

[0019] figure 1 It is a structural schematic diagram of the system of the present invention, as shown in the figure, the system includes a camera, a server, a switch and a plurality of client computers; the camera monitors the computer display running the HMI, and the camera area of the camera covers the entire display screen. And transmit the obtained video data to the server; the server extracts the background image of each sub-screen of the HMI, and gives the category mark; the server uses image processing and pattern recognition technology to extract and identify the process data from the real-time video collected by the camera, and the process The data is extracted and the HMI is reconstructed on the client computer using the background image.

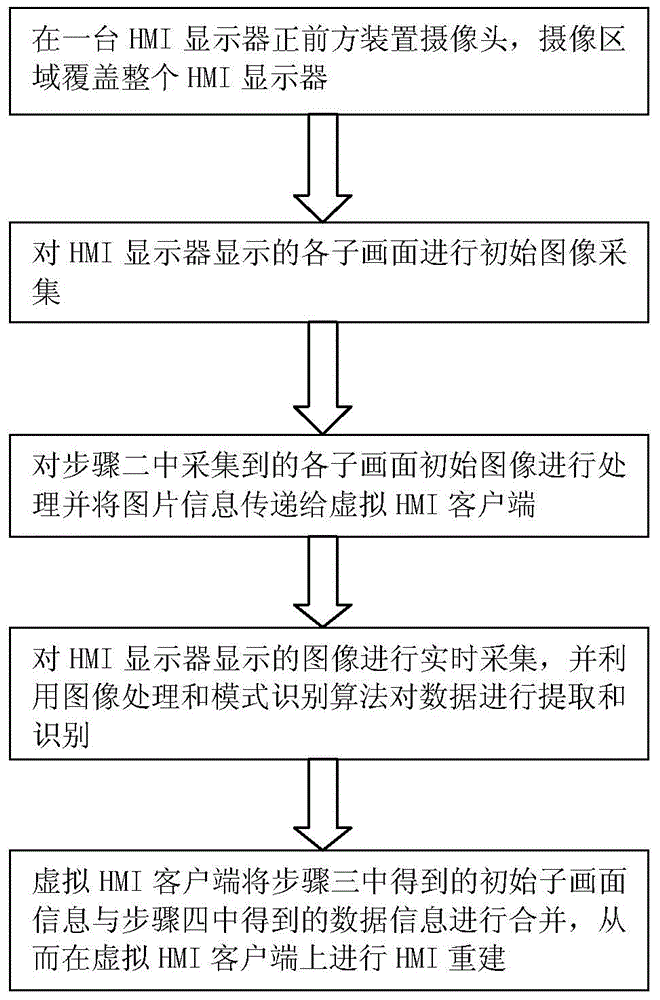

[0020] figure 2 It is a schematic flow chart of the method of the present invention, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com