Method for preventing doping ions from outgassing in process of ion implantation

A technology of doping ions and ion implantation, applied in the field of ion implantation, can solve the problems of electrical performance failure, change of silicon substrate resistance value, affecting the doping concentration of silicon substrate, etc., to achieve improved performance, excellent barrier properties and stability. , Guaranteed the effect of resistance value and electrical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

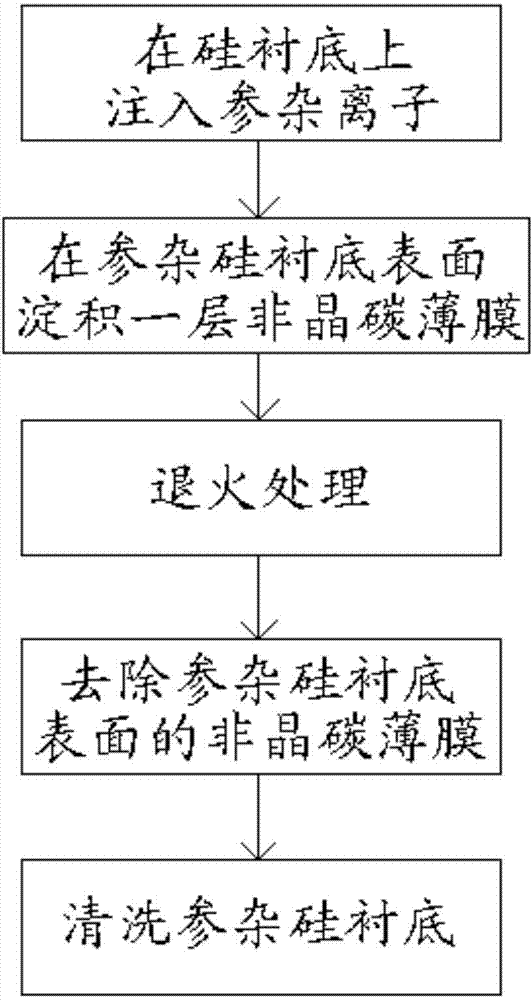

[0020] like figure 1 As shown, firstly, doping ions are implanted on the silicon substrate, and ion doping is performed in the area of the silicon substrate that needs to be doped to obtain a doped silicon substrate; then a layer of doped silicon substrate is deposited on the surface of the doped silicon substrate Amorphous carbon film, using plasma-enhanced chemical vapor deposition process to deposit a layer of amorphous carbon film with a thickness ranging from 100A to 10000A on a doped silicon wafer substrate at a temperature range of 200 ° C to 500 ° C; followed by annealing treatment, in During the annealing process, the doped silicon substrate with the amorphous carbon film is placed in N 2 or Ar or He for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com