A preparation method of thermally conductive and insulating aromatic nylon alloy material

A technology of heat conduction insulation and alloy materials, applied in the direction of heat exchange materials, insulators, organic insulators, etc., can solve the problems of poor thermal conductivity and poor thermal conductivity, improve impact strength, improve thermal conductivity, and enhance thermal conductivity performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

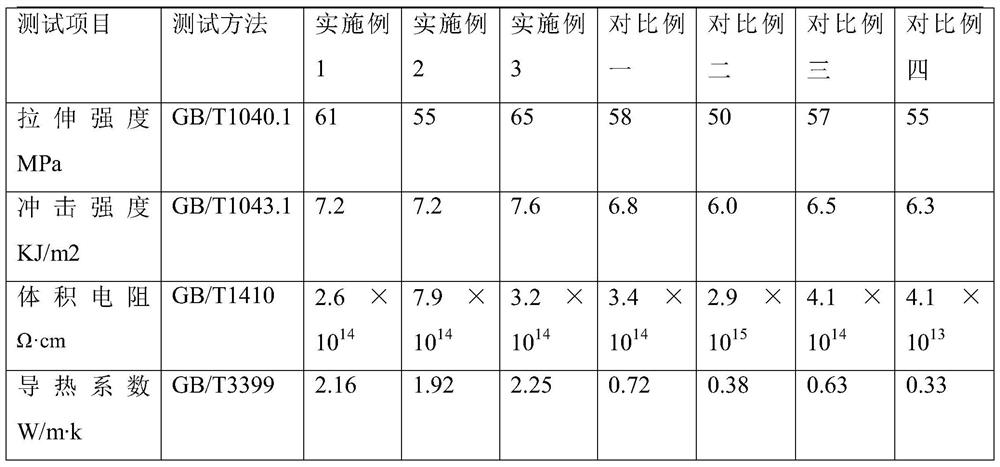

Examples

Embodiment 1

[0050] A heat-conducting and insulating aromatic nylon alloy material, comprising the following components by weight:

[0051] PA6T: 35 copies

[0052] PA66: 13 parts

[0053] Compatibilizer: 8 parts

[0054] Nylon pre-polymerized dispersed graphene: 3 parts

[0055] Aluminum nitride: 10 parts

[0056] Magnesium oxide: 10 parts

[0057] Carbon fiber: 3 parts

[0058] Graphite powder: 10 parts

[0059] Coupling agent: 3 parts

[0060] Lubricant: 0.1 parts

[0061] Antioxidant: 0.3 parts.

[0062] Described nylon prepolymerization dispersed graphene comprises following composition by weight:

[0063] Lauryl lactam: 55 parts

[0064] Caprolactam: 45 parts

[0065] Graphene mixture: 10 parts

[0066] N-acetyl caprolactam: 0.3 parts.

[0067] The preparation method of described nylon prepolymerized dispersed graphene is:

[0068] Step A: Add dry laurolactam and caprolactam monomers into the reactor, raise the temperature to 135°C, vacuumize for 30 minutes in the melte...

Embodiment 2

[0085] A heat-conducting and insulating aromatic nylon alloy material, comprising the following components by weight:

[0086] PA6T: 45 parts

[0087] PA66: 20 copies

[0088] Compatibilizer: 3 parts

[0089] Nylon pre-polymerized dispersed graphene: 8 parts

[0090] Aluminum nitride: 15 parts

[0091] Magnesium oxide: 0 parts

[0092] Carbon fiber: 5 parts

[0093] Graphite powder: 15 parts

[0094] Coupling agent: 1 part

[0095] Lubricant: 0.3 parts

[0096] Antioxidant: 0.5 parts.

[0097] Described nylon prepolymerization dispersed graphene comprises following composition by weight:

[0098] Lauryl lactam: 55 parts

[0099] Caprolactam: 45 parts

[0100] Graphene mixture: 10 parts

[0101] N-acetyl caprolactam: 0.3 parts.

[0102] The preparation method of described nylon prepolymerized dispersed graphene is:

[0103] Step A: Add dry laurolactam and caprolactam monomers into the reactor, raise the temperature to 135°C, vacuumize for 30 minutes in the melted ...

Embodiment 3

[0120] A heat-conducting and insulating aromatic nylon alloy material, comprising the following components by weight:

[0121] PA6T: 60 parts

[0122] PA66: 5 parts

[0123] Compatibilizer: 5 parts

[0124] Nylon pre-polymerized dispersed graphene: 15 parts

[0125] Aluminum nitride: 5 parts

[0126] Magnesium oxide: 10 parts

[0127] Carbon fiber: 8 parts

[0128] Graphite powder: 5 parts

[0129] Coupling agent: 2 parts

[0130] Lubricant: 0.5 parts

[0131] Antioxidant: 0.1 parts.

[0132] Described nylon prepolymerization dispersed graphene comprises following composition by weight:

[0133] Lauryl lactam: 55 parts

[0134] Caprolactam: 45 parts

[0135] Graphene mixture: 10 parts

[0136] N-acetyl caprolactam: 0.3 parts.

[0137] The preparation method of described nylon prepolymerized dispersed graphene is:

[0138] Step A: Add dry laurolactam and caprolactam monomers into the reactor, raise the temperature to 135°C, vacuumize for 30 minutes in the melted s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com