Shell structure and electronic device using same

A shell structure, electronic device technology, applied in the direction of telephone structure, telephone communication, electrical components, etc., can solve the problems of time-consuming, poor electrostatic protection, high manufacturing cost, etc., to prevent electromagnetic interference, light weight, beautiful appearance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

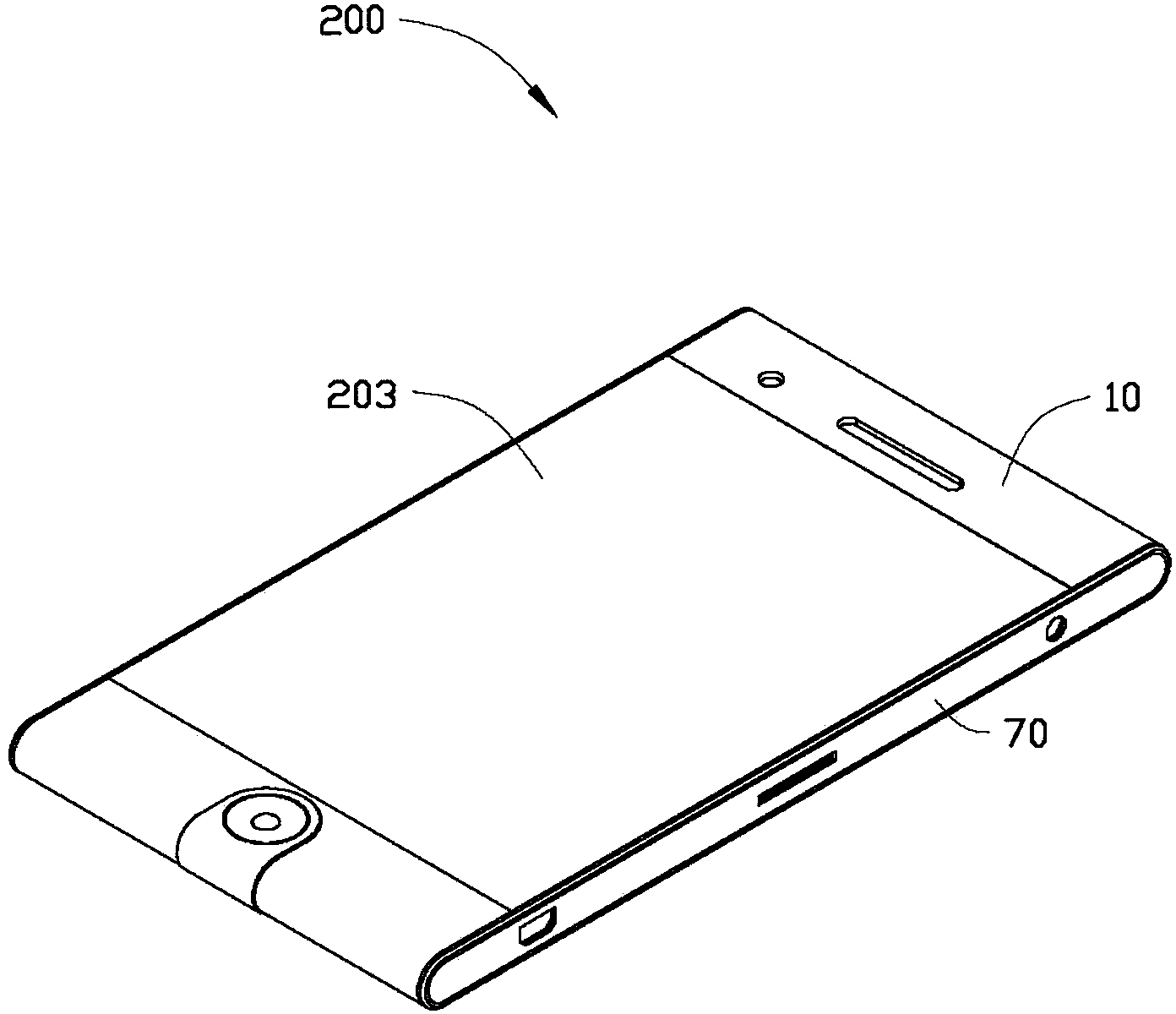

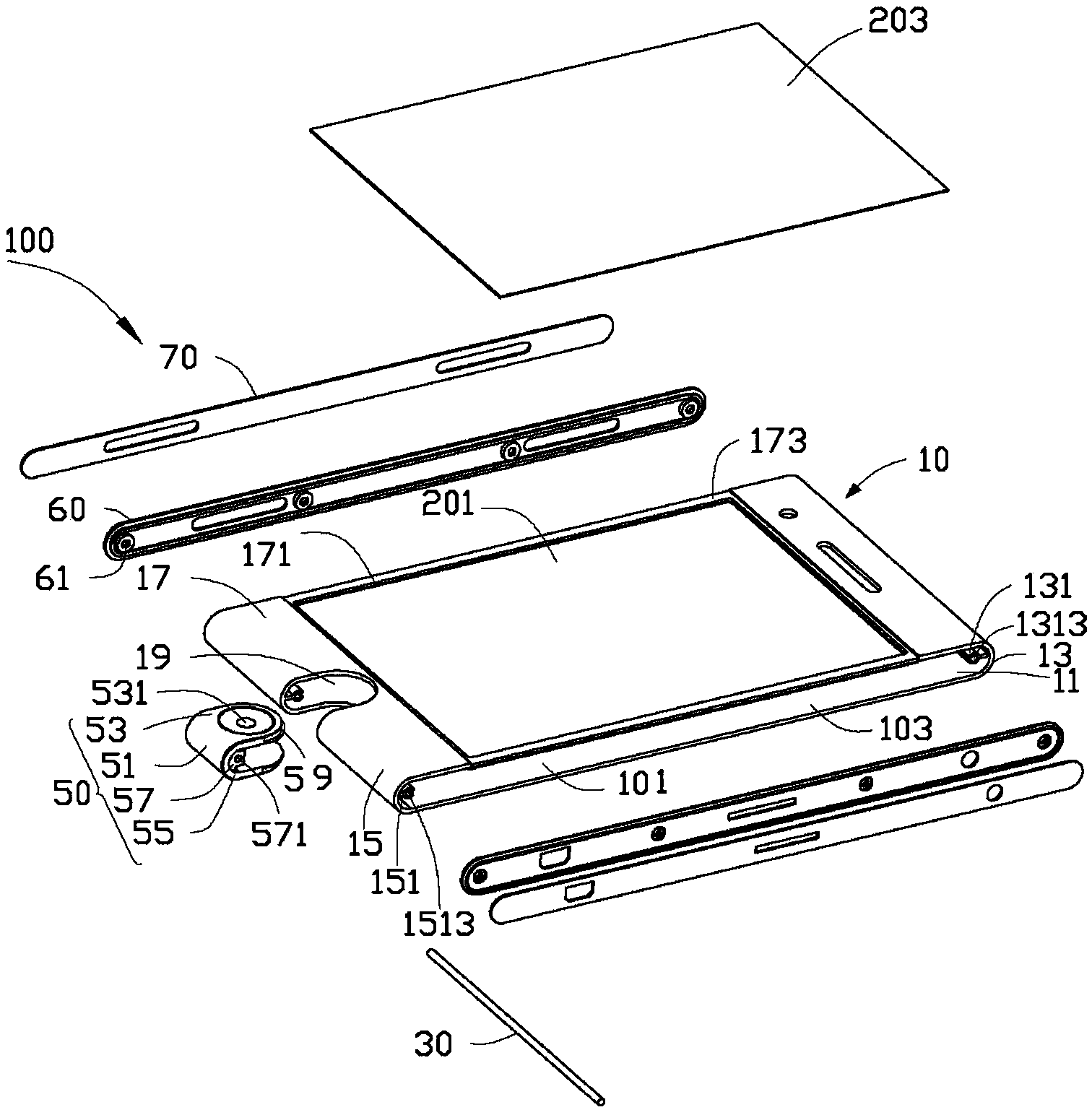

[0013] see figure 1 and figure 2 , the electronic device 200 according to the embodiment of the present invention includes a housing structure 100 , a display panel 201 , a protective screen 203 and internal electronic components (not shown). The display panel 201 and internal electronic components are accommodated in the casing structure 100 . The protective screen 203 is installed on the housing structure 100 and located above the display panel 201 . Internal electronic components include motherboard, CPU, audio components and other functional components, which are not described in detail here to save space. The display panel 201 is electrically connected to the main board of the internal electronic components.

[0014] The shell structure 100 includes a shell 10 , a connecting piece 30 , a button 50 , two mounting pieces 60 , two packaging pieces 70 and a protective screen 203 . The button 50 is mounted on one end of the casing 10 through the connecting piece 30 , and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com