Hydrogen station

一种氢罐、压缩机的技术,应用在氢技术、气体/液体分配与储存、船只建造细节等方向,能够解决控制、设备庞大、氢站难温度等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach )

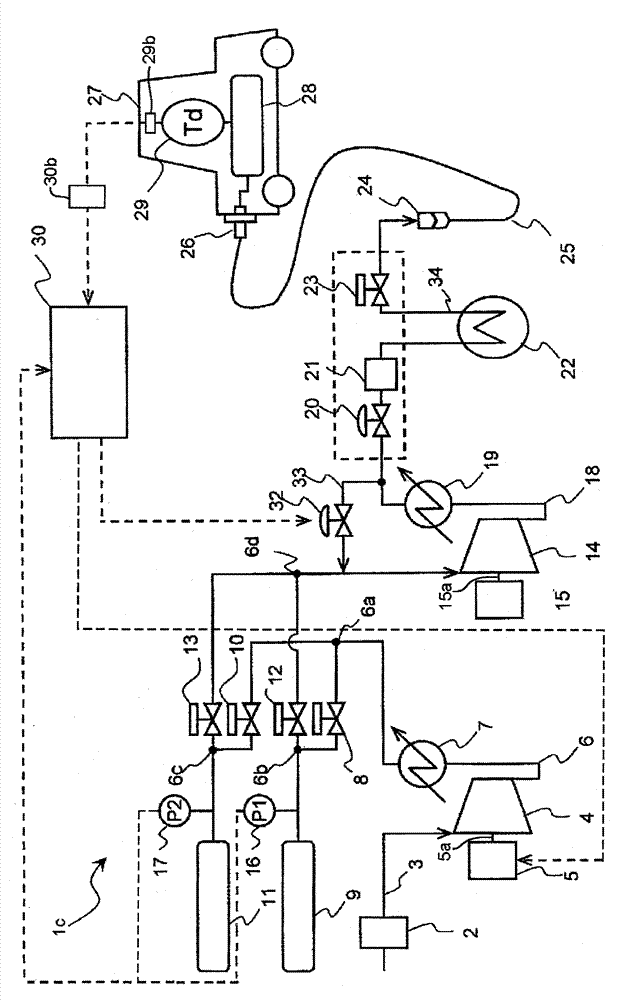

[0028] figure 1 The configuration of the hydrogen station 1 according to the first embodiment of the present invention is shown. This hydrogen station 1 is configured such that, firstly, the reciprocating compressor on the low-pressure stage side (the low-pressure side reciprocating compressor: the first compression machine) 4 to supply hydrogen (hydrogen gas).

[0029] A drive machine 5 (such as an electric motor) is connected to the low-pressure side reciprocating compressor 4 via a drive shaft 5 a. The low-pressure side reciprocating compressor 4 is driven by the rotation of a drive shaft 5 a of a drive machine 5 . The driving machine 5 is an electric motor driven by an inverter. The drive machine 5 is capable of rotational speed control, that is, the drive shaft 5 a can be rotated at an arbitrary rotational speed. In addition, the driving machine 5 is not limited to a motor driven by an inverter as long as the rotational speed can be controlled.

[0030] The hydrogen ...

no. 2 Embodiment approach )

[0083] Figure 4 The configuration of the hydrogen station 1b according to the second embodiment of the present invention is shown. This hydrogen station 1b shares almost all of its configuration with the hydrogen station 1 related to the above-mentioned first embodiment. In addition, the same code|symbol is used for the same structure as said 1st Embodiment, and detailed description is abbreviate|omitted.

[0084] In the hydrogen station 1b of this embodiment, two intermediate pressure accumulators (the first intermediate pressure accumulator 9 and the second intermediate pressure accumulator 11) are provided, and the high pressure side reciprocating compression The machine 14 is different from the hydrogen station 1 of the first embodiment in that a flywheel 31 is provided on a drive shaft 15 a connected to the drive machine 15 . Furthermore, the hydrogen station 1b of the present embodiment is also different from the hydrogen station 1 of the first embodiment in that the ...

no. 3 Embodiment approach )

[0098] Figure 5 The configuration of a hydrogen station 1c according to a third embodiment of the present invention is shown. This hydrogen station 1c shares almost all of its configuration with the hydrogen station 1b related to the above-mentioned second embodiment. In addition, the same code|symbol is used for the same structure as said 2nd Embodiment, and detailed description is abbreviate|omitted.

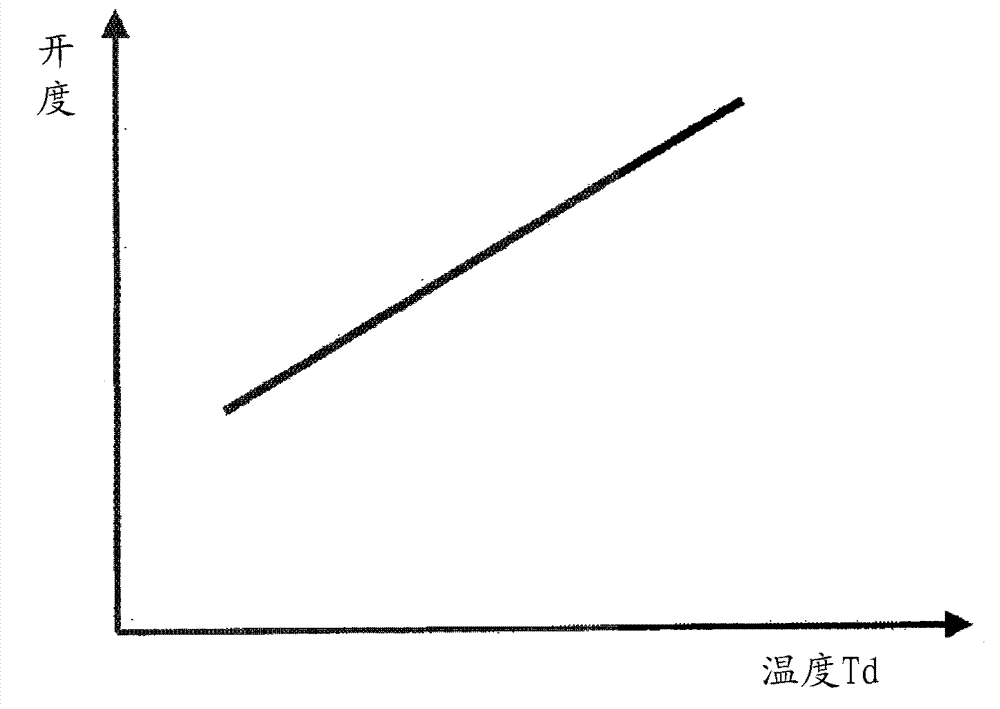

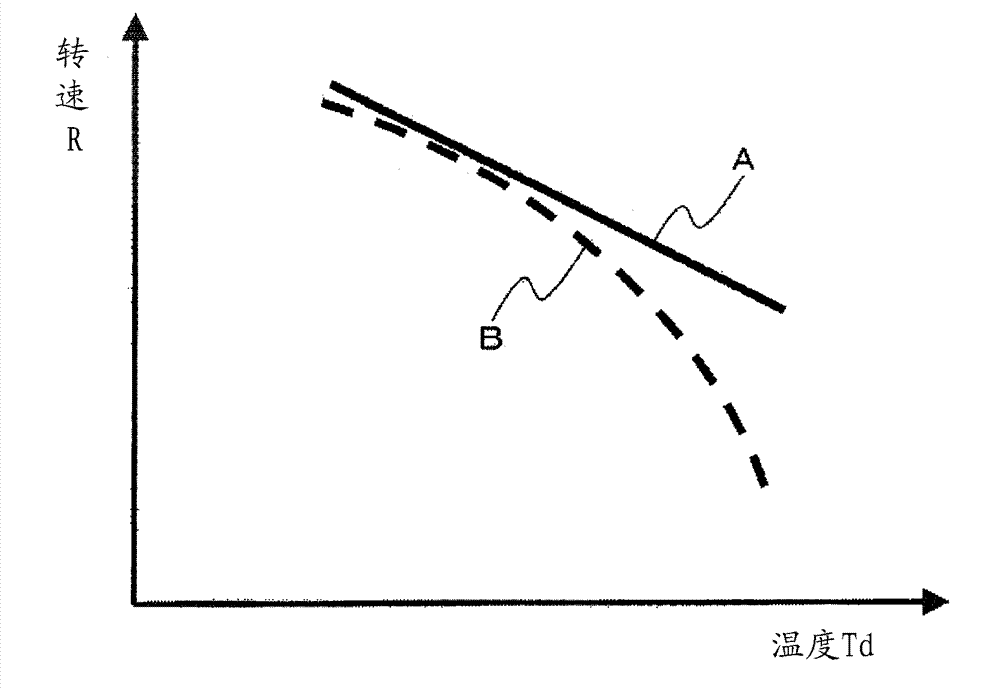

[0099] In the hydrogen station 1b of the second embodiment, the rotation speed of the driving machine 15 is controlled based on the temperature Td. On the other hand, in the hydrogen station 1b of the present embodiment, the opening degree of the adjustment valve 32, which will be described later, is adjusted based on the temperature Td. It is different in that the amount of hydrogen (return amount) returned from the discharge side to the suction side of the high-pressure side reciprocating compressor 14 via the return flow path 33 described later is adjusted.

[0100] In t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com