All-optical hydrophone that is not sensitive to temperature or static pressure

A hydrophone and temperature change technology, which is applied in the direction of instruments, scientific instruments, seismic signal receivers, etc., can solve the problem that the axial deformation is not enough to obtain the sensitivity of the hydrophone

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

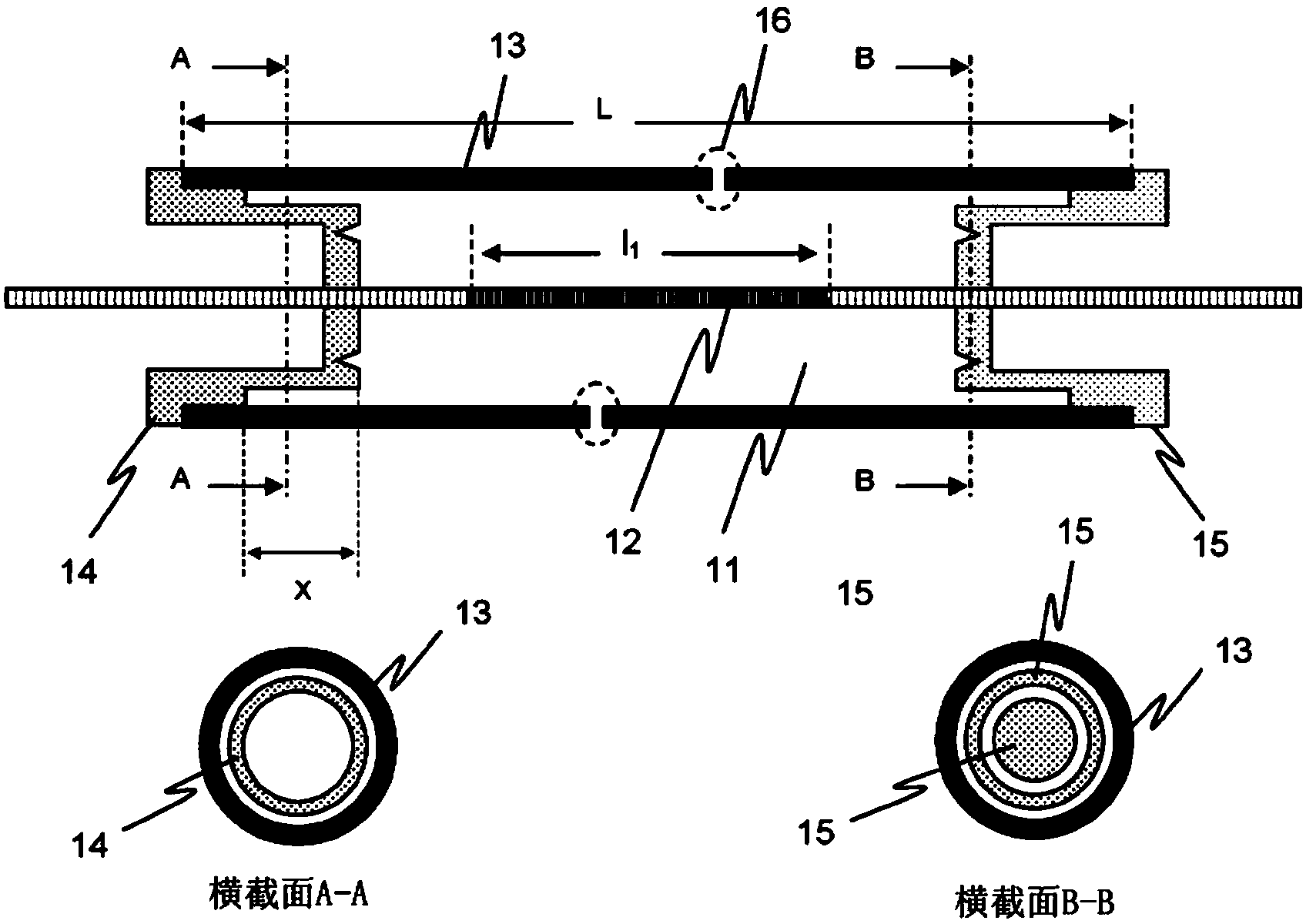

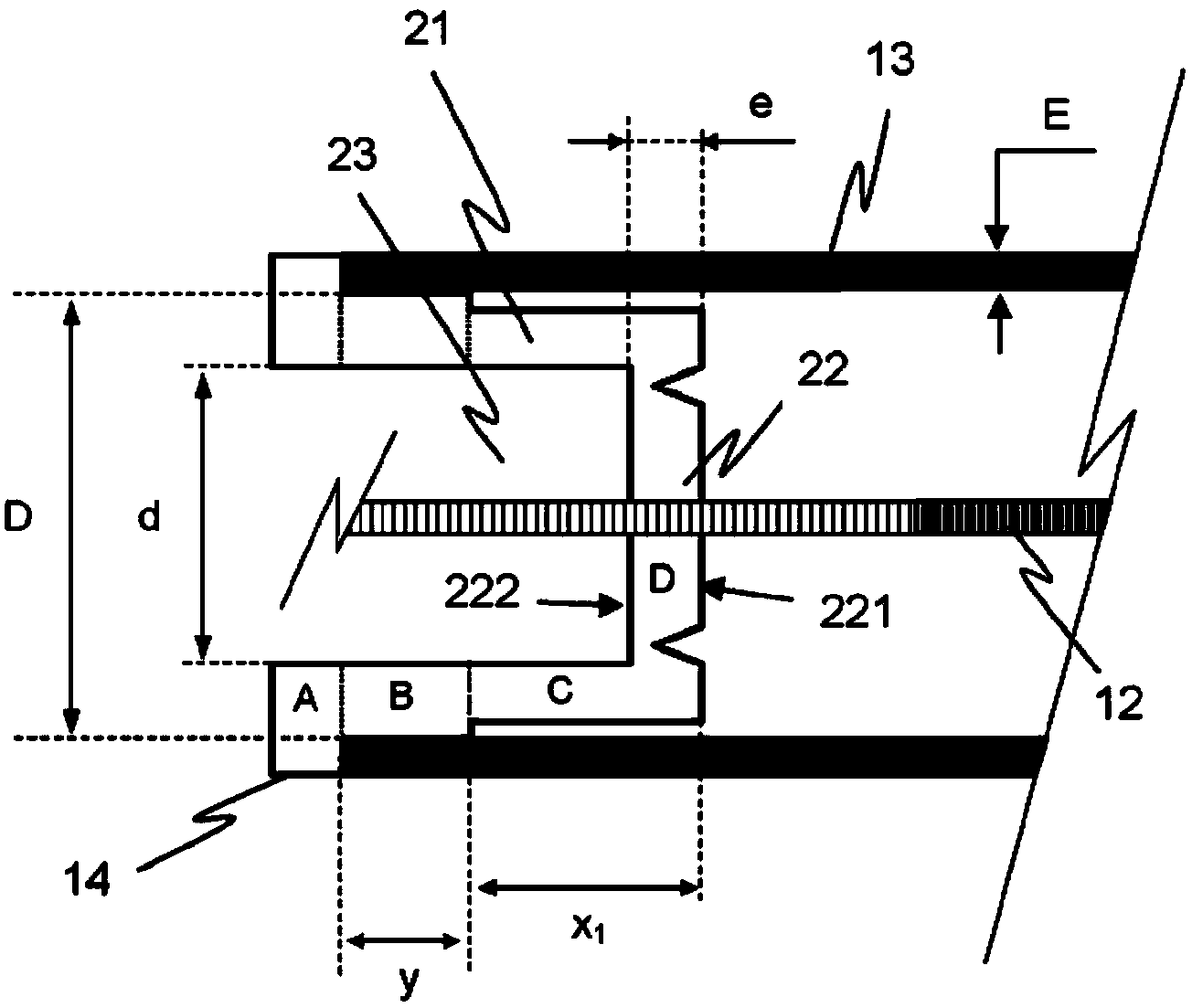

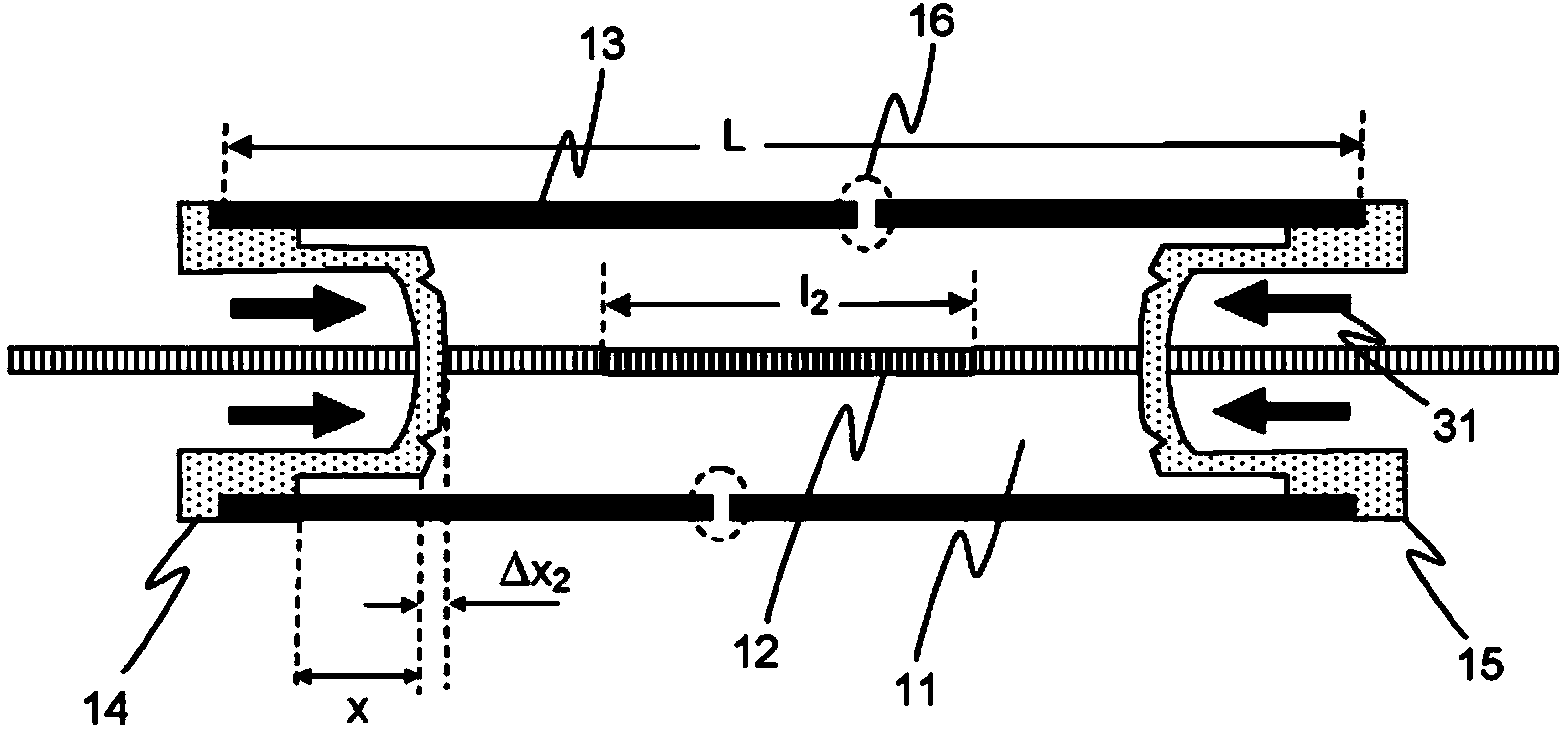

[0052] The following description presents the characteristics of the optical hydrophone according to the invention by means of a preferred embodiment, which is used here as an exemplary embodiment and does not limit the scope or breadth of the invention. pass Figure 1 to Figure 6 In particular, the structure of this particular embodiment is illustrated, along with an explanation of the principles of its operation.

[0053] The hydrophone according to the invention comprises a protective mechanical structure defining a cavity 11 inside which a Bragg grating fiber optic element 12 is placed. In addition to the shielding function, this cavity also has the function of amplifying, in a known manner, the axial deformations exerted on the fiber optic element 12 by the dynamic pressure exerted by the external medium.

[0054] In a known manner, the fiber optic element 12 constituting the Bragg-grating fiber single-frequency laser cavity (which forms the sensitive part of the hydroph...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com